Mixed ventilation cooling system and method for permanent magnet traction motor

A traction motor, ventilation and cooling technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of low indirect cooling efficiency of permanent magnets, affect the heat transfer of permanent magnets, and it is difficult to ensure the heat dissipation capacity, etc., to achieve Balance temperature rise, enhance heat dissipation, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

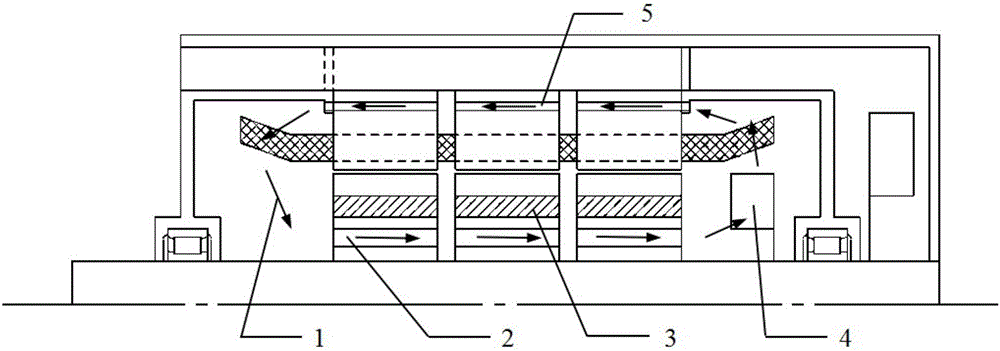

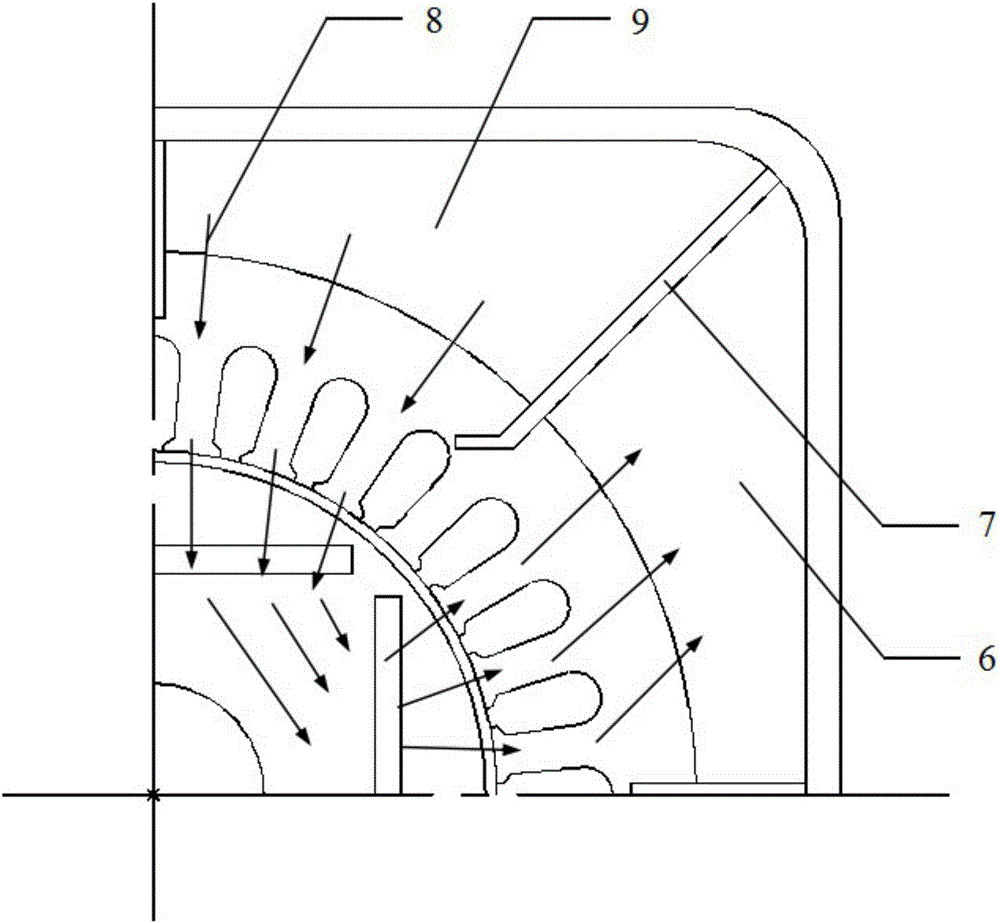

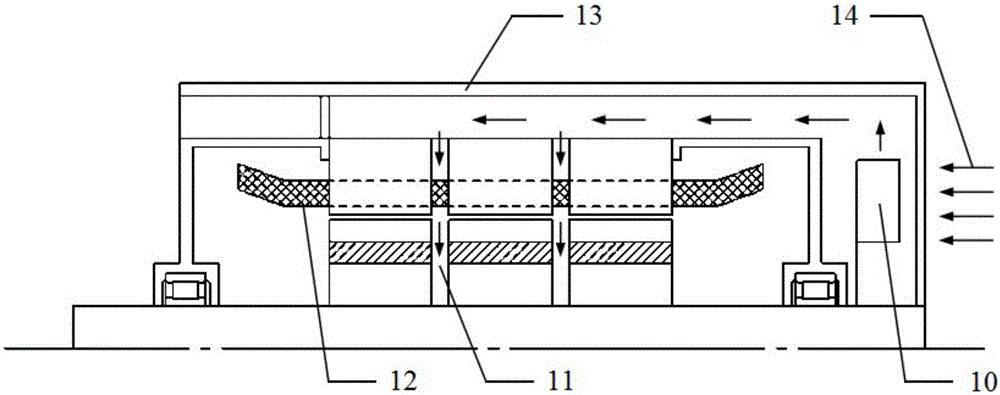

[0031] The present invention proposes a hybrid ventilation and cooling system for permanent magnet traction motors, such as Figure 1~Figure 5 As shown, the bearing 17 of the motor is installed between the end cover 20 and the rotating shaft 21 , the stator coil 12 is wound in the slot of the stator core 19 , and the permanent magnet 3 is built in the rotor core 18 . The cooling system is divided into radial ventilation system and axial ventilation system.

[0032] Axial ventilation system includes rotor core laminations punched out of rotor axial ventilation hole configuration and stacked to form rotor axial ventilation hole 2, stator core laminations punched out of stator axial ventilation hole configuration and laminated to form stator shaft To the ventilation hole 5, and the centrifugal fan 4 of the axial air path; the centrifugal fan 4 of the axial air path is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com