Low-profile lens antenna based on reflective array feed

A technology of lens antennas and reflectarrays, which is applied in the direction of antennas and electrical components, can solve the problems of limiting the application range of folded reflectarrays, the inability to achieve dual polarization or circular polarization, and increasing processing and production costs, achieving multiple degrees of design freedom , short preparation cycle and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

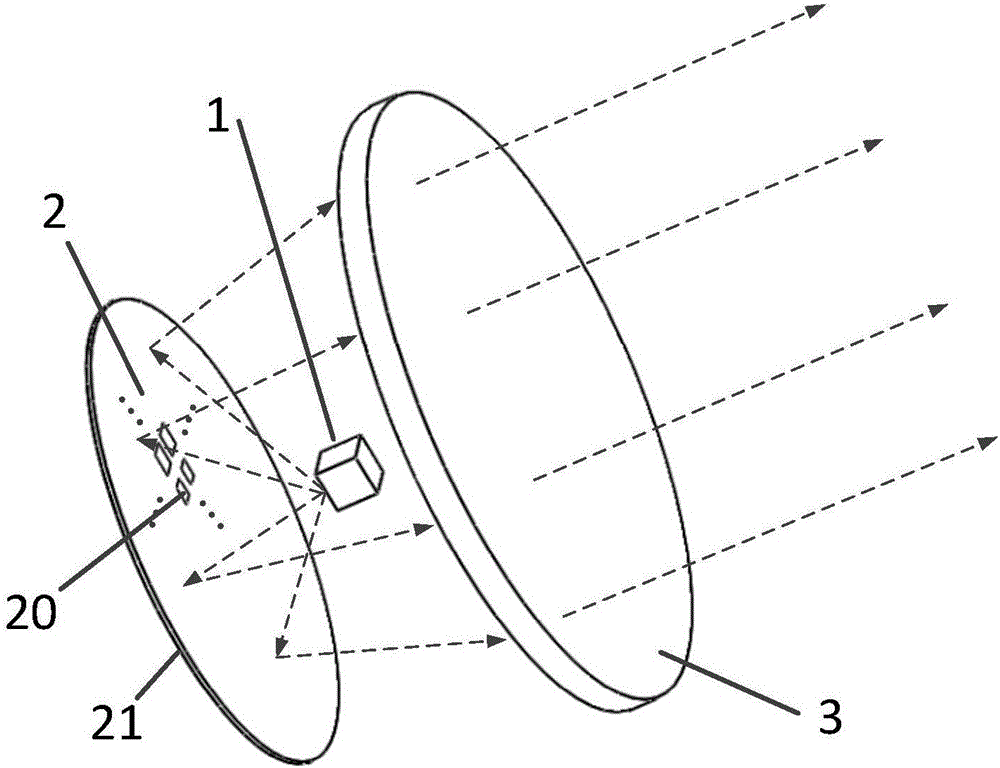

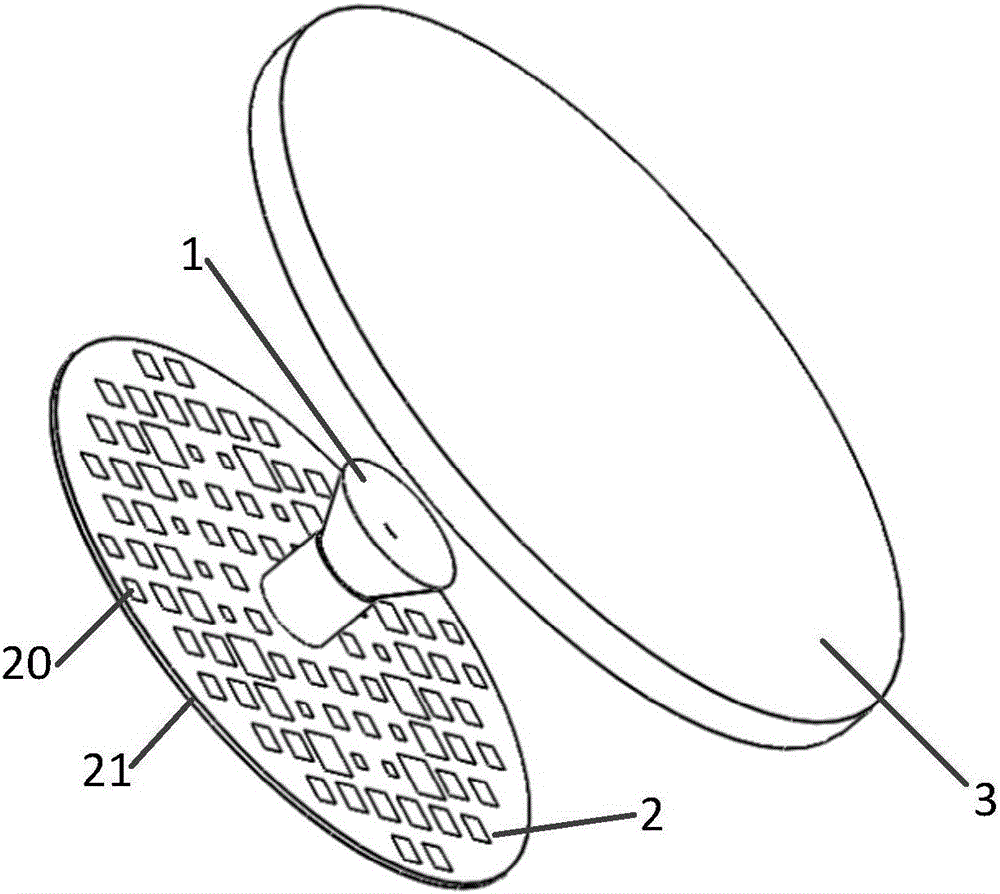

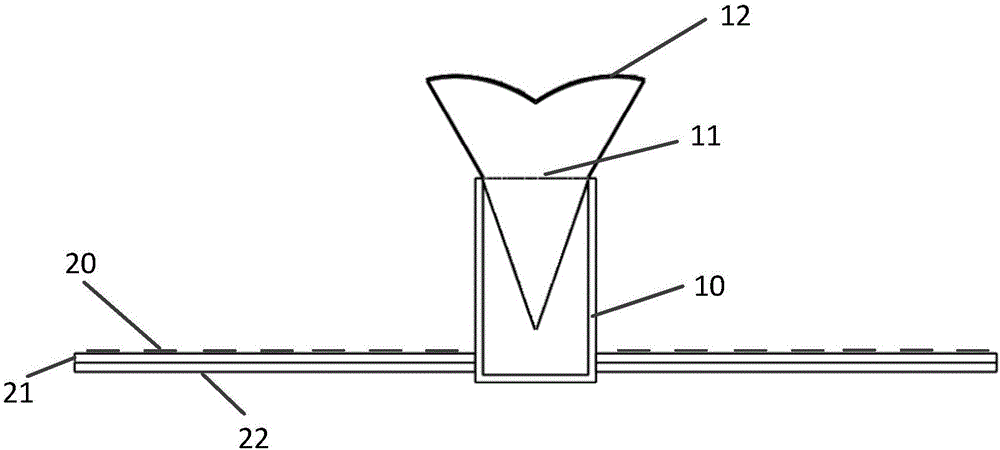

[0024] In this example, the ring-focus Cassegrain reflector array is used to feed the lens. The overall structure is as follows: figure 2 As shown, it includes a ring-focus feed 1 supported by a dielectric block 11 , a plate reflection array 2 printed with a microstrip patch unit 20 located at the bottom of the ring-focus feed 1 , and a lens 3 located above the ring-focus feed 1 . The schematic diagram of the structure of the specific ring-focus feed and reflector array is as follows: image 3 As shown, the ring-focus feed source is composed of a C120 standard circular waveguide 10 with a radius of 8.737mm, a dielectric block 11 embedded in the standard circular waveguide, and a metal sub-reflector 12 coated on the top of the dielectric block 11. The dielectric block 11 adopts the dielectric constant The polytetrafluoroethylene material of 2.2 is used for impedance matching and supporting the metal sub-reflecting surface 12 . The flat reflector array 2 is composed of 92 rect...

Embodiment 2

[0027] The reflectarray-fed lens antenna in this example uses a common feed horn to feed the reflectarray. The overall structure is as follows: Figure 5 As shown, the primary horn is a conical horn 1 supported by four support rods 13 , the reflection array and lens adopt a rectangular aperture, and other structures are the same as those described in Embodiment 1 in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com