A lithium titanate secondary battery

A secondary battery and lithium titanate technology, which is applied in the field of lithium ion batteries, can solve the problems of affecting battery stability, low reduction potential, and inability to effectively isolate direct contact with the lithium titanate surface, so as to improve the low-temperature performance of the battery and reduce dissolution , Reduce the effect of battery gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

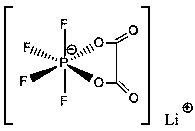

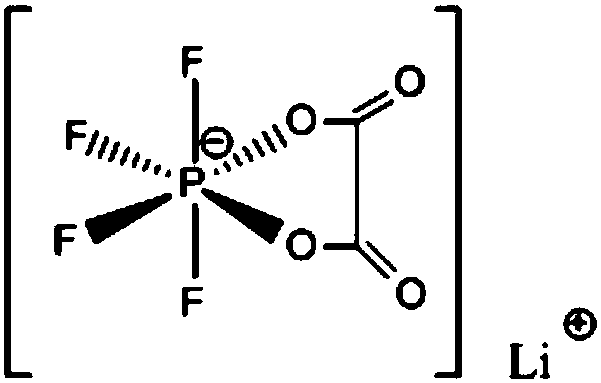

[0023] Preparation of PC-based electrolyte: in an argon atmosphere glove box (H 2 O6 ) and 0.03M lithium difluorophosphate (LiPO 2 f 2 ) electrolyte lithium salt, and then sequentially add 1% lithium tetrafluorooxalate phosphate (LTFOP) and 1.0% vinyl sulfate (DTD) based on the mass percentage of the electrolyte, and stir well to obtain the present invention. PC based electrolyte (free acid <15ppm, moisture <10ppm).

[0024] Preparation of nickel-cobalt lithium manganese oxide positive electrode sheet: nickel-cobalt lithium manganese oxide (type 111) is used as the positive electrode active material, and polyvinylidene fluoride (PVDF) and conductive carbon black (Super-P) are added in a mass ratio of 96:2:2 Mix in N-methylpyrrolidone (NMP) solvent, stir to obtain a slurry, apply it on both sides of the current collector aluminum foil on a coating machine, dry, cold press, and slitting to obtain a positive electrode sheet;

[0025] Preparation of lithium titanate negative el...

Embodiment 2~5

[0031] Embodiment 2~5 and comparative example 1~5

[0032] In Examples 2-5 and Comparative Examples 1-5, except that the composition of the electrolyte solution is added as shown in Table 1, the others are the same as in Example 1. Table 1 is the composition of the electrolyte solution and battery performance test results of Examples 1-5 and Comparative Examples 1-5:

[0033]

[0034] Table 1

[0035] In the above Table 1, the abbreviations / chemical formula corresponding names of each chemical substance are as follows:

[0036] PC (propylene carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), PP (propyl propionate), EC (ethylene carbonate), LiPF 6 (lithium hexafluorophosphate), LiPO 2 f 2 (lithium difluorophosphate), LiFSI (lithium difluorosulfonimide), LiDFOB (lithium difluorooxalate borate).

[0037] From the comparison of the battery performance test results between the examples in Table 1 and Comparative Examples 1-4, it can be seen that lithium tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com