PERC preparation method

A technology for batteries and silicon wafers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of easy formation of voids in aluminum paste filling and reduce the effect of back passivation, so as to achieve power improvement, reduce the proportion of aluminum-silicon voids, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

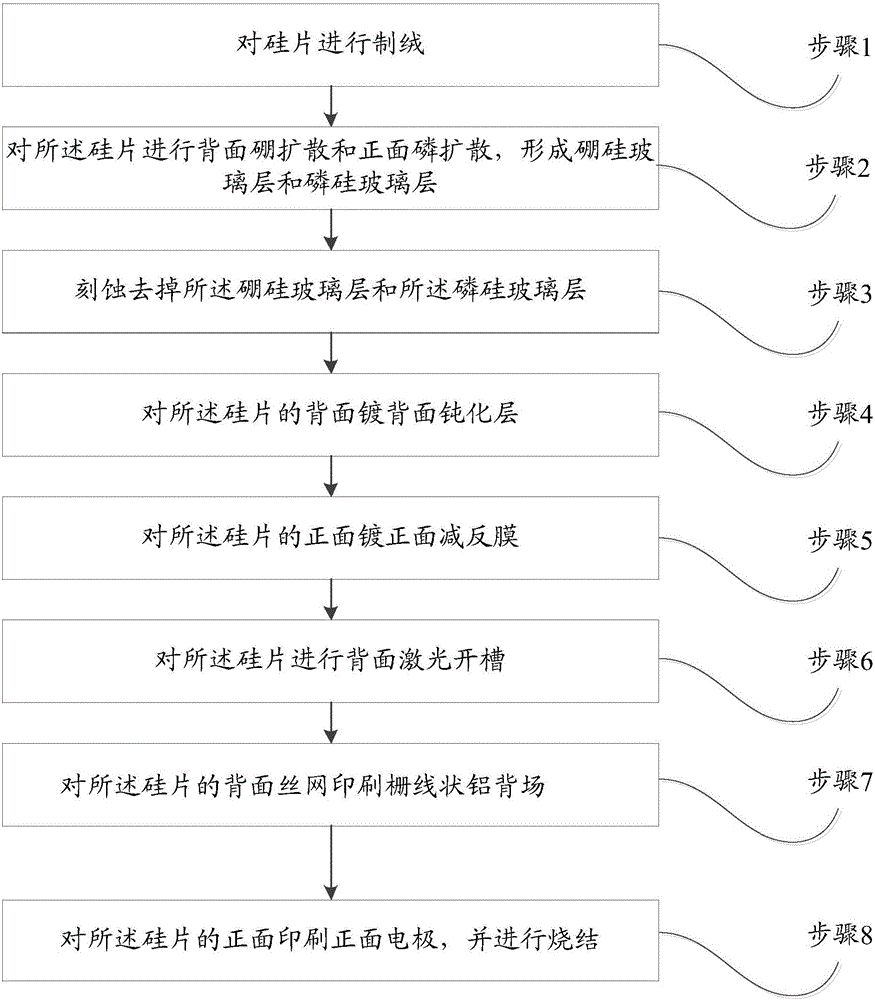

[0031] Based on this, an embodiment of the present invention provides a method for preparing a PERC battery, including:

[0032] Step 1, texturing the silicon wafer;

[0033] Step 2, performing boron diffusion on the back side and phosphorus diffusion on the front side of the silicon wafer to form a borosilicate glass layer and a phosphosilicate glass layer;

[0034] Step 3, etching and removing the borosilicate glass layer and the phosphosilicate glass layer;

[0035] Step 4, plating a back passivation layer on the back side of the silicon wafer;

[0036] Step 5, coating the front side of the silicon wafer with an anti-reflection film;

[0037] Step 6, performing laser grooving on the back side of the silicon wafer;

[0038] Step 7, screen-printing a grid-like aluminum back field on the back of the silicon wafer;

[0039] Step 8, printing a front electrode on the front surface of the silicon wafer, and performing sintering.

[0040] In summary, the PERC battery preparati...

Embodiment 1

[0057] Take 500 pieces of monocrystalline silicon wafers, and perform conventional PERC texturing, diffusion, etching, rear aluminum oxide, rear silicon nitride, front silicon nitride, and rear laser grooving (30-50um line width). Print grid-shaped back electric field by means of screen printing - the screen line width of the grid-shaped aluminum back field is 25 μm to 30 μm, print the front electrode, sinter, and complete the preparation of the battery. The maximum efficiency of the manufactured single crystal PERC battery can reach To 20.55%.

Embodiment 2

[0059] The screen line width of the grid-shaped aluminum back field is 35 μm to 40 μm, and conventional PERC texturing, diffusion, etching, aluminum oxide on the back, silicon nitride on the back, silicon nitride on the front, and laser grooving on the back (42um line width) process, print the grid-shaped back electric field by screen printing-the screen line width of the grid-shaped aluminum back field is 35 μm to 40 μm, print the front electrode, sinter, and complete the preparation of the battery. The maximum efficiency of monocrystalline PERC cells can reach 20.45%.

[0060] From the test results of the above comparative examples and examples, it can be seen that: the grid-shaped back electric field is easier to mass-produce, saving aluminum paste and reducing production costs, and the efficiency is also increased; at the same time, PERC cells made of double-sided diffusion superimposed grid-shaped aluminum back field, It has the effect of double-sided cells, and has a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com