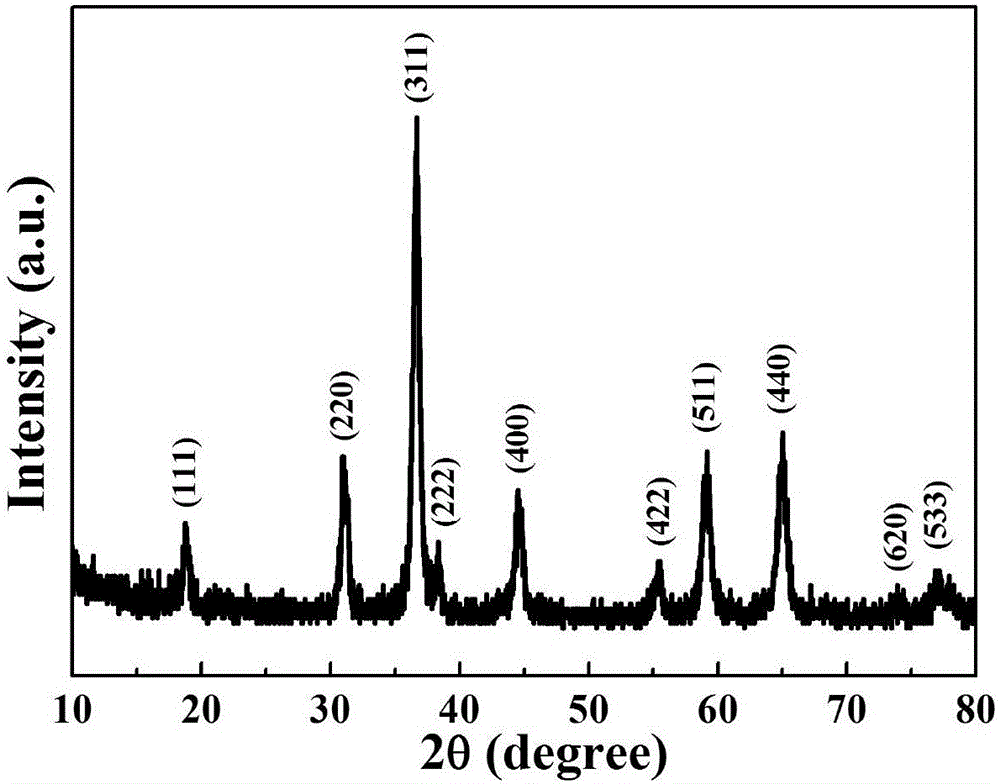

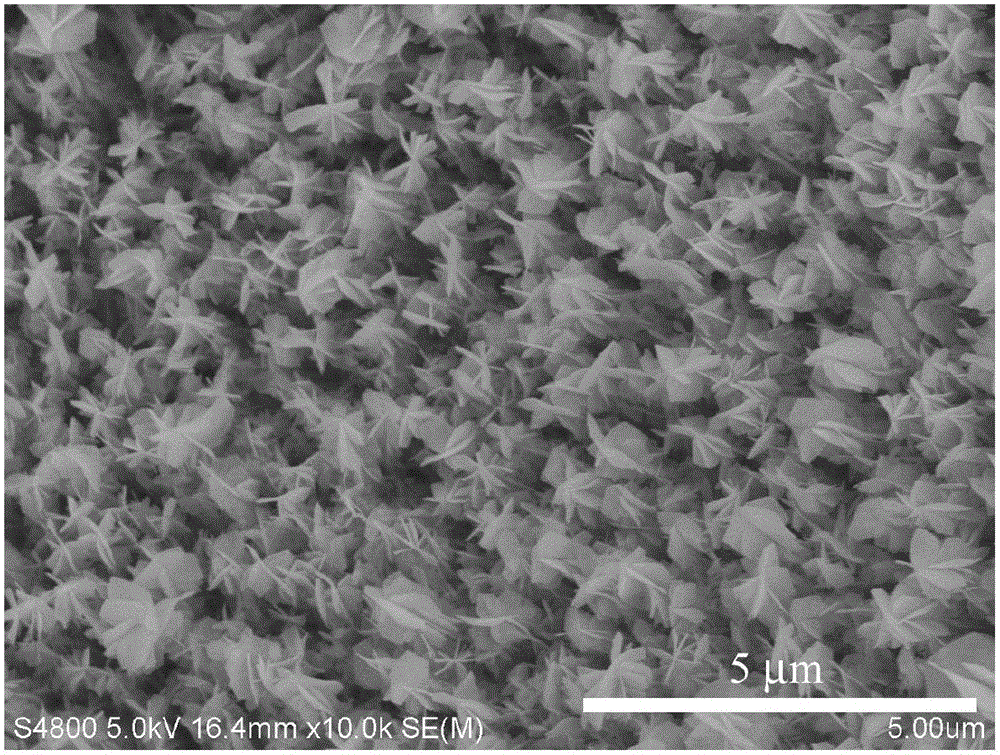

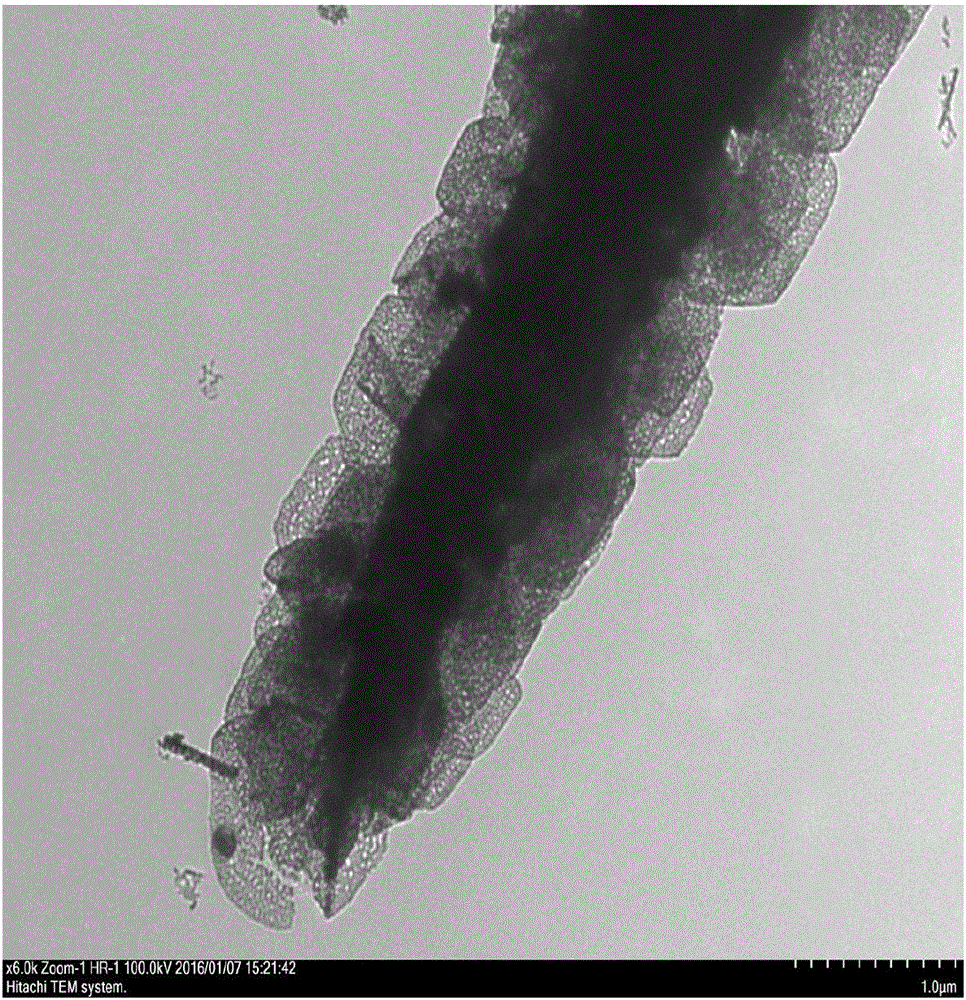

Mesoporous Co3O4 nano-wire @ NiCo2O4 nanoplate graded core-shell array material, preparation method and application

A technology of nanowires and nanosheets, which is applied in nanomaterial preparation methods and electrochemical cross-application fields, can solve problems such as poor rate capacity, and achieve the effects of improving specific capacitance, convenient and fast transmission, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A mesoporous Co 3 O 4 Nanowire @NiCo 2 O 4 The preparation method of nanosheet graded core-shell array material includes the following steps:

[0037] (1) 1.5mmol Co(NO 3 ) 2 ·6H 2 O and 1 mmol of tetrabutylammonium bromide were dissolved in 40 mL of deionized water, followed by the addition of 2 mmol of NaHCO 3 , and continued stirring for 20 min to obtain solution A. The solution A was transferred to a 50mL polytetrafluoroethylene-lined reaction kettle, and the pretreated 2×3cm nickel foam (first soaked in 6M dilute hydrochloric acid for 10min to remove the outer oxide film, and then washed with deionized water) ) obliquely in the solution, sealed and heated at 180°C for 12h, naturally cooled to room temperature. The nickel foam covering the sample was washed three times with deionized water and absolute ethanol, and dried in a vacuum drying oven at 60 °C for 6 h.

[0038] (2) 0.1 mmol Ni (NO 3 ) 2 ·6H 2 O, 0.2 mmol Co(NO 3 ) 2 ·6H 2 O and 0.1 mmol tetr...

Embodiment 2

[0042] A mesoporous Co 3 O 4 Nanowire @NiCo 2 O 4 Application of nanosheet graded core-shell array materials as electrode materials for asymmetric supercapacitors.

[0043] The specific application method is: using mesoporous Co 3 O 4 Nanowire @NiCo 2 O 4 Nanosheet Hierarchical Core-Shell Array Materials for Cathode and MoS 2 The material was used as the negative electrode to assemble an asymmetric supercapacitor device, and the 3M KOH solution was used as the electrolyte to measure the cyclic voltammetry curve, galvanostatic charge-discharge and charge-discharge cycles using a CHI 660D electrochemical workstation. Cyclic voltammetry curves tested at 10, 25, 50 and 100mV s -1 At different scanning speeds, the voltage range is 0 to 1.35V, and the results are as follows Figure 5 shown. at 10 to 100mV s -1 There is no obvious distortion in the CV curves in the scan rate range, indicating the fast charge-discharge characteristics of asymmetric supercapacitors. And it ...

Embodiment 3

[0045] A mesoporous Co 3 O 4 Nanowire @NiCo 2 O 4 The preparation method of nanosheet graded core-shell array material includes the following steps:

[0046] (1) 1.5mmol Co(NO 3 ) 2 ·6H 2 O and 1 mmol of tetrabutylammonium bromide were dissolved in 40 mL of deionized water, followed by the addition of 2 mmol of NaHCO 3, and continued stirring for 20 min to obtain solution A. The solution A was transferred to a 50mL polytetrafluoroethylene-lined reaction kettle, and the pretreated 2×3cm nickel foam (first soaked in 6M dilute hydrochloric acid for 10min to remove the outer oxide film, and then washed with deionized water) ) obliquely placed in the solution, sealed and heated at 180°C for 9h, naturally cooled to room temperature. The nickel foam covering the sample was washed three times with deionized water and absolute ethanol, and dried in a vacuum drying oven at 60 °C for 6 h.

[0047] (2) 0.1 mmol Ni (NO 3 ) 2 ·6H 2 O, 0.2 mmol Co(NO 3 ) 2 ·6H 2 O and 0.1 mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com