Sapphire camera lens and manufacturing method thereof

A sapphire and camera technology, applied in the field of camera lenses, can solve the problems of low processing accuracy, affecting the photographing process, reducing the transmittance of incident light, etc., to achieve the effect of improving imaging clarity, reducing interference intensity, and increasing appearance aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

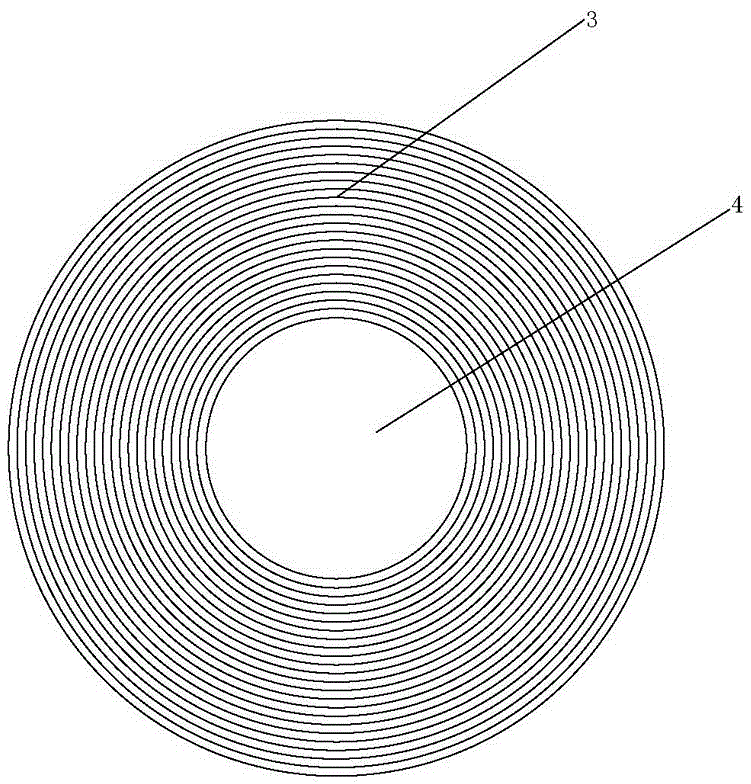

[0040] A method for preparing a sapphire camera lens. The sapphire camera lens is prepared by combining nanoimprinting and plasma dry etching, wherein the nearest neighbor distance of the anti-reflection nano-pattern array is 50nm-300nm, and the period of the photonic crystal is 300nm-2μm. , as attached image 3 As shown, it specifically includes the following steps:

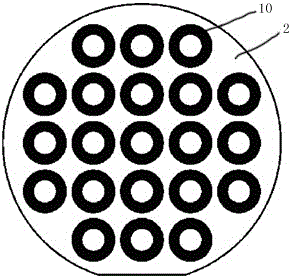

[0041] S1, firstly polish the 2-4 inch sapphire substrate 2 on both sides, control the thickness of the polished sapphire substrate to 0.2mm-0.7mm, and clean and remove the pollutants on the surface of the sapphire substrate.

[0042] S2, spin coating a photoresist layer 5 suitable for UV nanoimprinting on the front side of the sapphire substrate 2, the thickness of the photoresist layer is 100nm-600nm, and the thickness of the photoresist layer depends on the etching resistance and antireflection of the glue itself The height of the nano-pattern bulge; put the sapphire substrate with a photoresist layer on the...

Embodiment 2

[0049] A method of realizing sapphire camera lens by using nanosphere self-assembly method, stepping photolithography method and plasma dry etching method, in which the nearest neighbor distance is 100nm by using nanosphere self-assembly method combined with plasma dry etching method The 300nm anti-reflection nano pattern array adopts the stepping photolithography method to prepare the photonic crystal structure with a period of 2μm-10μm, which specifically includes the following preparation steps:

[0050] S1, polishing a 2-4 inch sapphire substrate on both sides, controlling the thickness of the polished sapphire substrate to 0.2mm-0.7mm, cleaning and removing pollutants on the surface of the sapphire substrate.

[0051] S2, first SiO with a diameter of 100nm to 300nm 2 Nanosphere materials diluted into organic solvents and controlled SiO 2 The concentration and ratio of nanospheres; then immerse the sapphire substrate obliquely into the solvent, and deposit a single layer ...

Embodiment 3

[0058] The method of realizing sapphire camera lens by using anodic aluminum oxide (AAO) method, stepping photolithography method combined with plasma dry etching method, wherein the nearest neighbor spacing is 100nm~ by using AAO technology combined with plasma dry etching method The 300nm anti-reflection nano-pattern convex array adopts stepping photolithography technology to prepare a photoresist crystal structure with a period of 2 μm to 10 μm, which specifically includes the following preparation steps:

[0059] S1, polishing a 2-4 inch sapphire substrate on both sides, controlling the thickness of the polished sapphire substrate to 0.2mm-0.7mm, cleaning and removing pollutants on the surface of the sapphire substrate.

[0060] S2, using anodized aluminum oxide (AAO) method to prepare AAO thin film layer with nearest neighbor spacing of 100nm-300nm; use corrosion to separate AAO thin film layer from aluminum substrate, and conduct through-hole treatment; attach AAO thin fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com