Electric-heat-aging junction temperature calculation model establishing method of IGBT module

A technology for establishing a method and a calculation model, which is applied in the field of establishment of an electric-thermal-aging junction temperature calculation model, and can solve problems such as inaccurate prediction results of the junction temperature of the electric-thermal coupling model, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

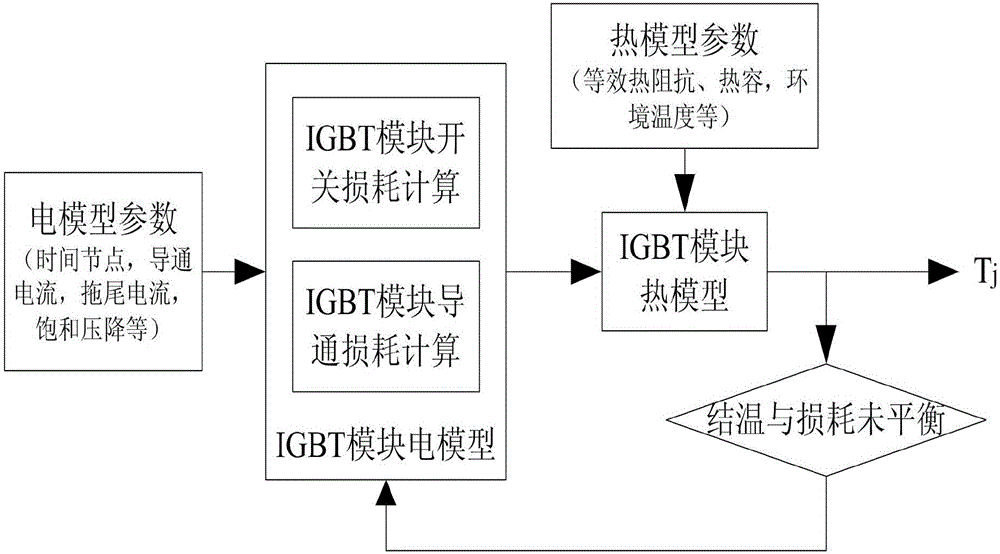

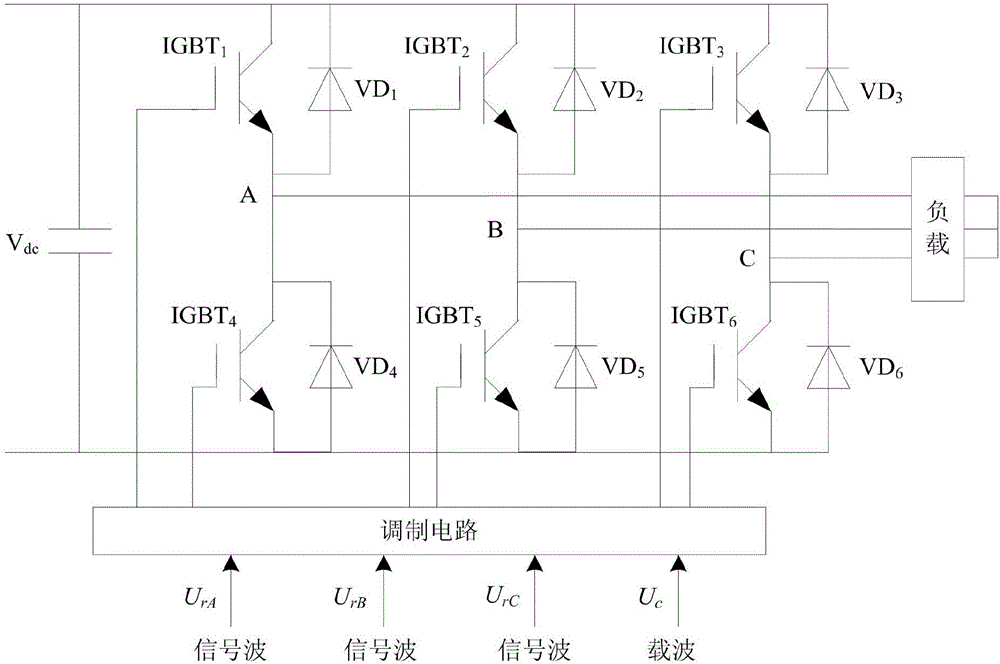

[0063] figure 1 A block diagram of the electric-thermal coupling model of the IGBT module is given. Below to figure 2 The three-phase six-bridge inverter circuit shown is taken as an example to introduce the establishment process of the electric-thermal-aging junction temperature calculation model in detail. The IGBT module is MMG75S120B from Macmic Company. The module consists of two identical parts, each part consists of an IGBT and a diode, and the rated conditions of the IGBT and the diode are 1200V / 75A. The chip is soldered to the DCB substrate through lead-free solder paste, and the upper part of the chip is connected to the DCB substrate through aluminum bonding wires.

[0064] The electric-thermal-aging junction temperature calculation model establishment method of IGBT module of the present invention comprises the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com