Drilling system for weak cemented rock test piece

A rock specimen and weakly cemented technology, applied in sampling devices and other directions, can solve the problems of weakly cemented rock cannot meet actual production, weakly cemented rock particles have a low degree of cohesion, and rock particles are easily softened and disintegrated by water. Good health, ensure integrity, avoid the effect of poor drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

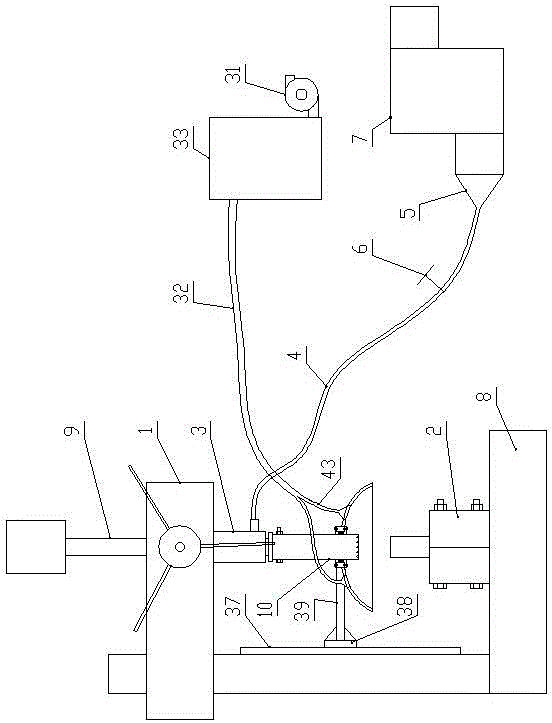

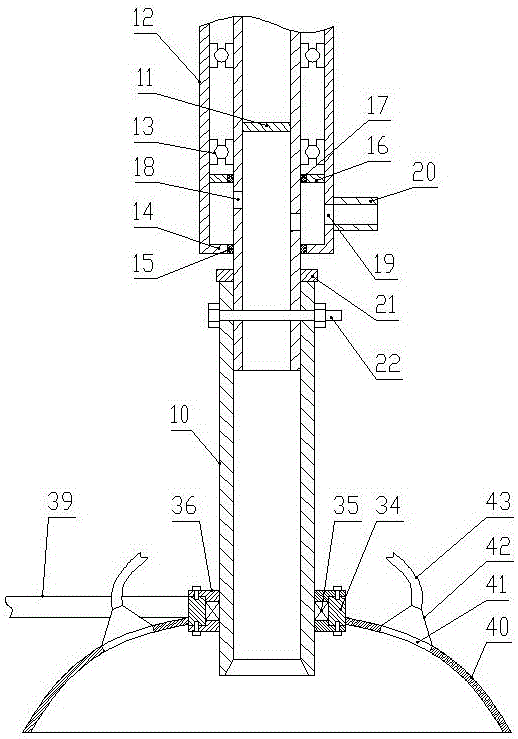

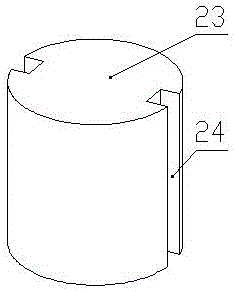

[0017] like figure 1 , figure 2 and image 3 As shown, the rock weakly cemented rock specimen drilling system of the present invention includes a rocker drill 1, a clamp 2, a sealing connection device 3, an air guide pipe 4, an air collecting cover 5, an air volume regulating valve 6 and a blower 7; the clamp 2 It is arranged on the platform 8 of the rocker drill 1, and the blower 7 is arranged on one side of the rocker drill 1. The drill rod 9 of the rocker drill 1 is a hollow structure, and the lower end of the drill rod 9 is connected with a drill tube 10 coaxially. 9. A sealing connection device 3 located above the drill tube 10 is provided on the outside, and a baffle plate 11 located above the drill tube 10 is provided inside the drill rod 9. The air outlet of the blower 7 is connected to one end of the air guide pipe 4 through the wind collecting cover 5. The other end of the air guiding pipe 4 is connected with the sealing connecting device 3 , and the air outlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com