Square steel tube column-H-shaped steel beam end-plate connecting node

A technology for connecting nodes and square steel pipes, which is applied to the connection nodes between square steel pipe columns and H-shaped steel beams, and the connection nodes between steel structure beams and columns, which can solve the problems of complex construction, high cost, and heavy welding workload, and achieve The effect of less on-site workload, high node domain stiffness, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

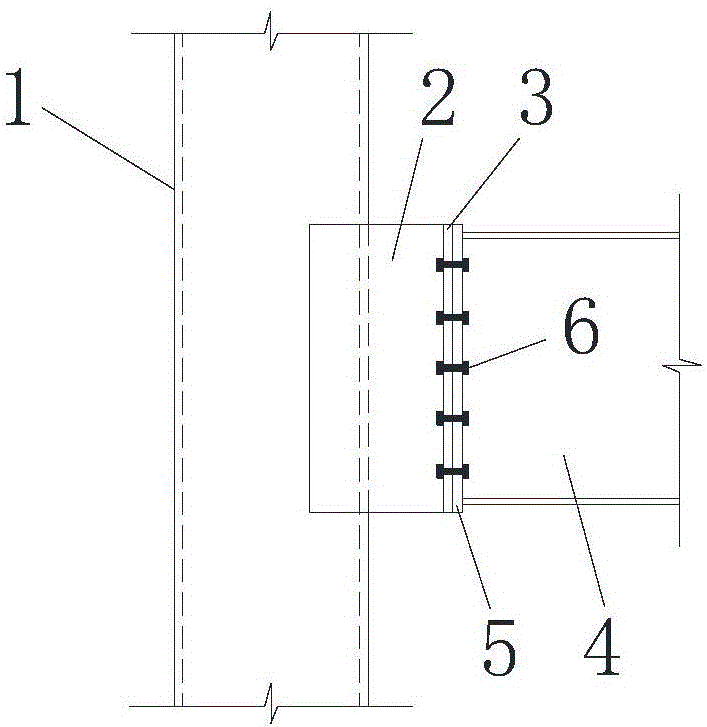

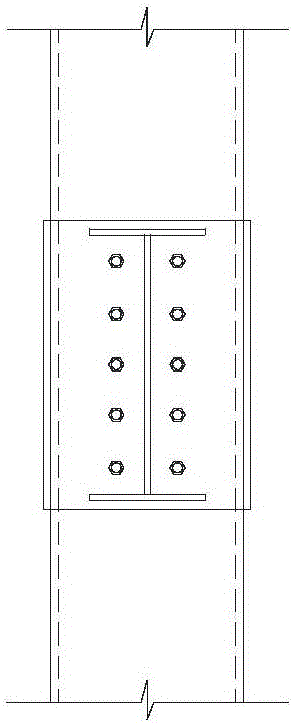

[0020] The present invention is an end-plate connection node of a square steel pipe column and an H-shaped steel beam—a flat end-plate connection node, such as Figure 1~3 As shown, it includes square steel pipe column 1, side steel plate 2, node end plate 3, H-shaped steel beam 4, beam end plate 5, and friction type high-strength bolt 6. The side steel plate 2 is welded to the square steel pipe column 1; the node end plate 3 is welded to the extended end of the side steel plate 3; the beam end plate 5 is welded to the end of the H-shaped steel beam 4; the square steel pipe column 1 and the H-shaped steel beam 4 The node end plate 3 and the beam end plate 5 are connected as a whole through friction type high-strength bolts 6 . The welding method, plate thickness and weld size of the side steel plate and the side wall of the square steel pipe are calculated and determined according to the "Code for Design of Steel Structures" (GB50017-2003). The welding of side steel plates an...

Embodiment 2

[0022] Such as Figure 4~6 As shown, the end plate connection node of a square steel pipe column and the H-shaped steel beam of the present invention—the outrigger end plate connection node, its component composition, processing and installation are similar to the flat end plate connection node, the difference is that the beam end plate 5 Stiffeners 7 are respectively welded at the upper and lower flanges corresponding to the 4 legs of the H-shaped steel beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com