SiC epitaxial growth master disk structure with satellite disks auto-rotating

An epitaxial growth, satellite disk technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of three 6-inch SiC wafers without self-rotation function, etc., to achieve high uniformity and improve the uniformity between wafers , Improve the effect of intra-chip uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

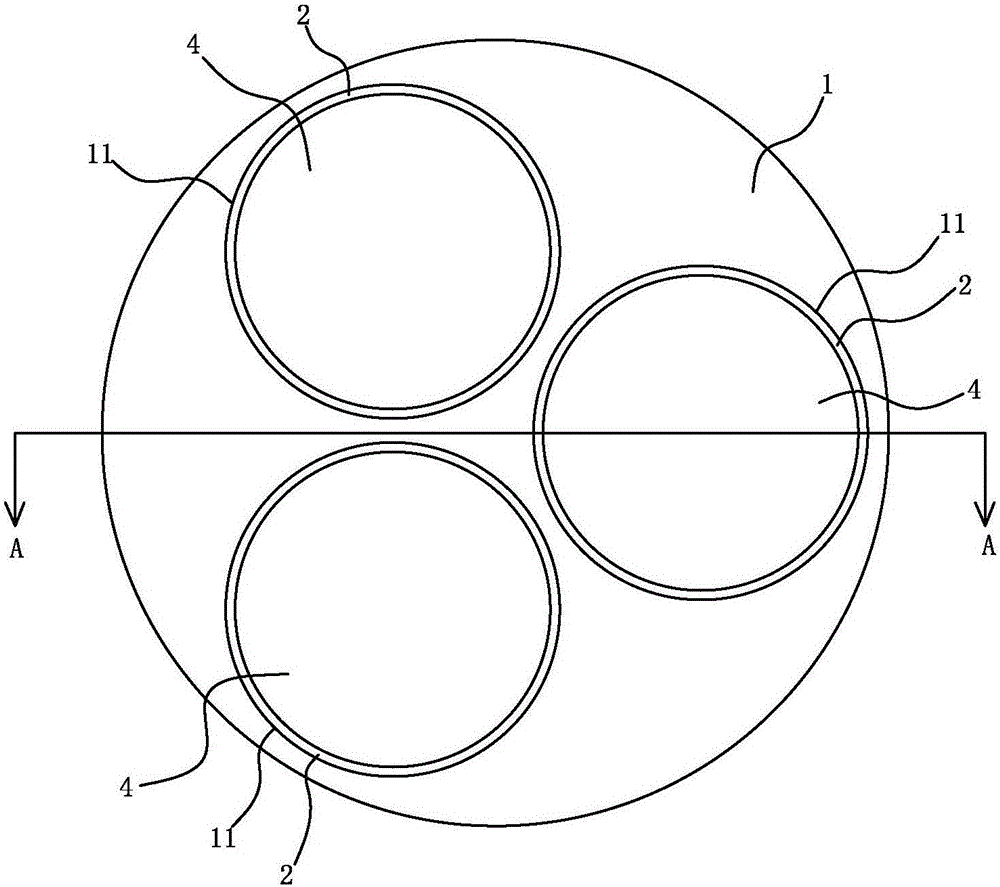

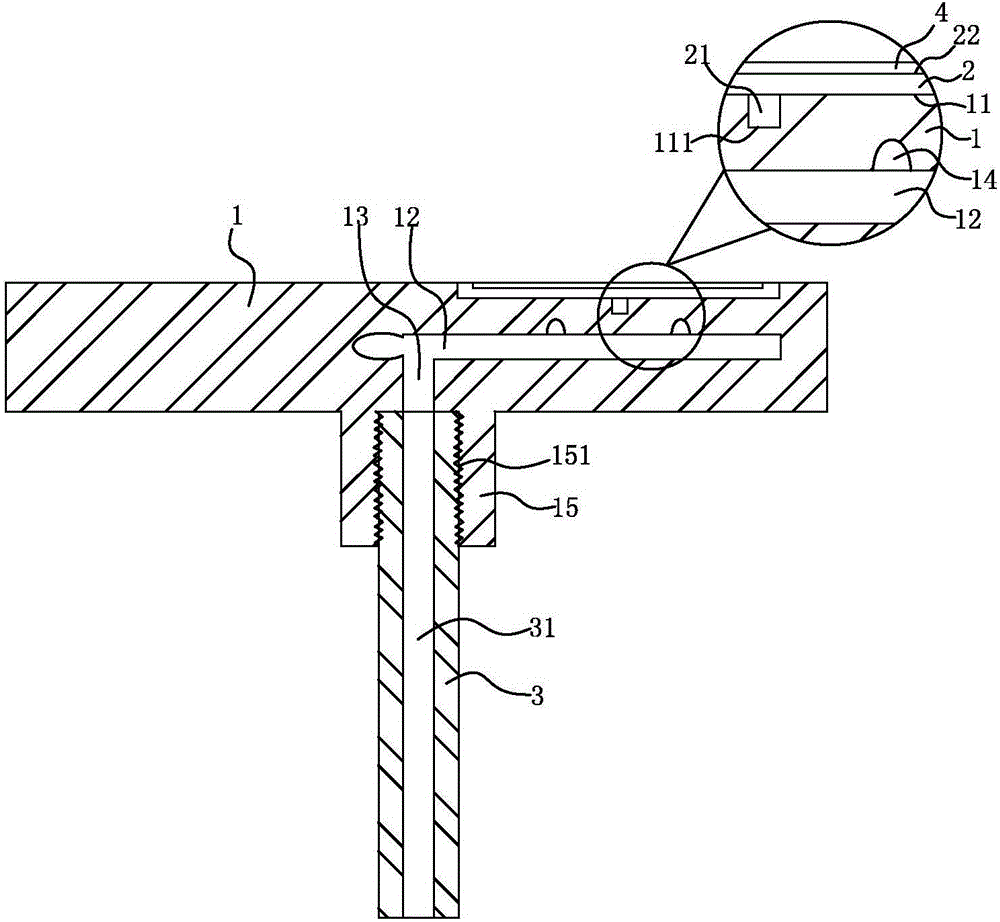

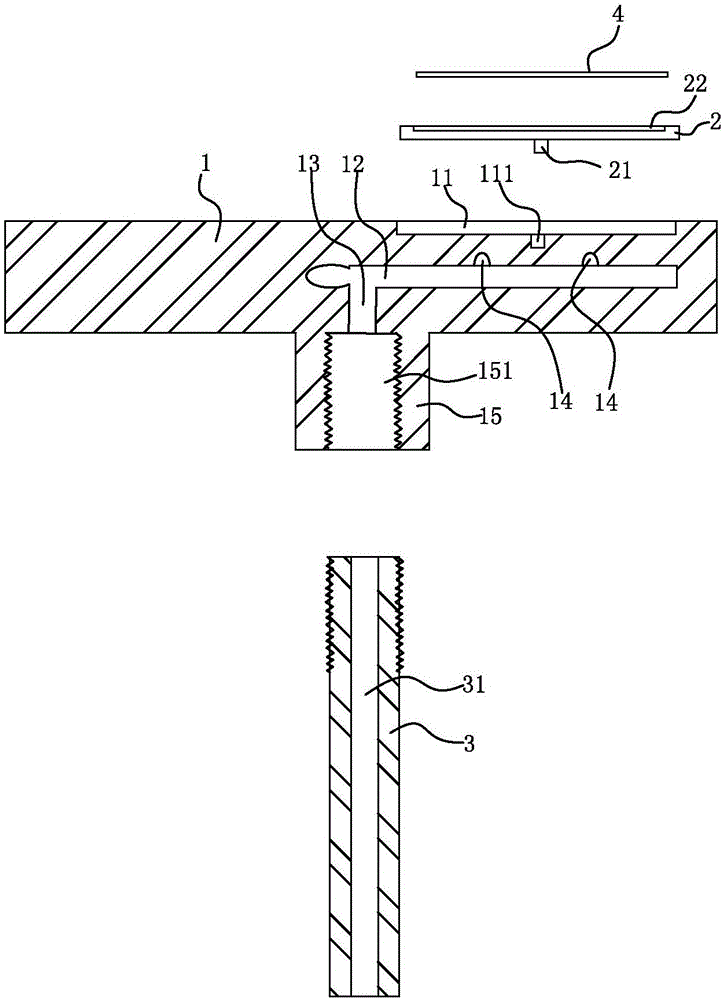

[0035] See Figure 1-5 As shown, it is a SiC epitaxial growth master disk structure with satellite disk rotation, which includes: a main rotating disk 1, a number of satellite disks 2 installed in the main rotating disk 1 and used to carry SiC wafers 4, and fixed on the main rotating disk 1 The supporting rod 3 at the lower end, the satellite dish 2 can rotate by itself.

[0036] The main rotating disk 1 is a circular disk, and the main rotating disk 1 is provided with a plurality of tray grooves 11; specifically, the number of the tray grooves 11 is three, which are arranged along three diameters with an included angle of 120°. direction and equidistant from the center of the main rotating disk 1.

[0037] The satellite plate 2 is used to carry the SiC wafer 4 , which is rotatably installed in the tray groove 11 of the main rotating plate 1 . S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com