Diffusion flow equalizing plate used for horizontal diffusion furnace

A technology of diffusion furnace and equalizing plate, applied in the directions of diffusion/doping, crystal growth, electrical components, etc., to achieve the effect of uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

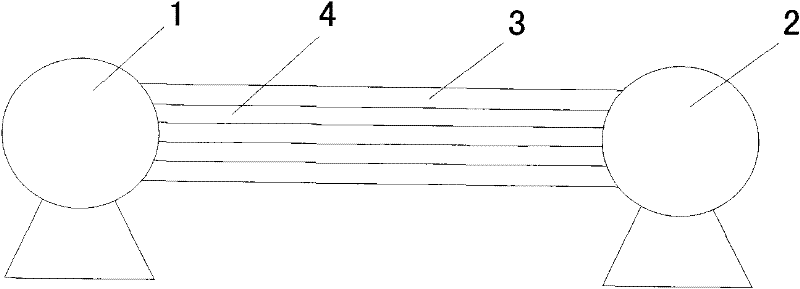

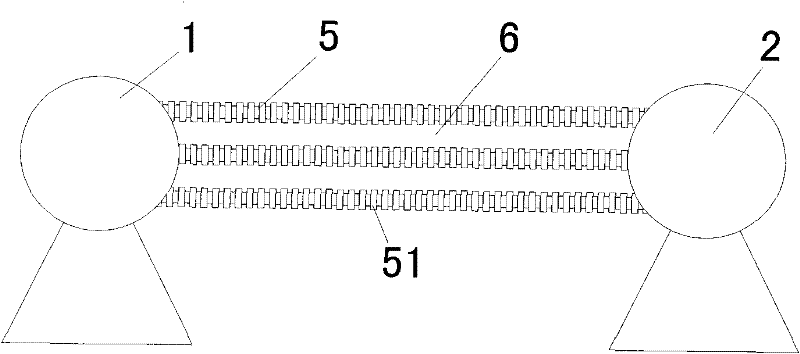

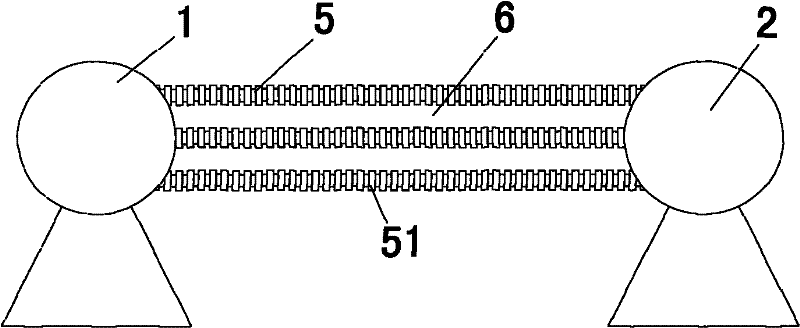

[0011] see figure 2 , the present invention is used for the diffusion equalizer of the horizontal diffusion furnace, including the inlet pipe 1, the outlet pipe 2 and a plurality of connecting pipes 5 connected between the inlet pipe and the outlet pipe, wherein the connecting pipes 5 are hollow bellows connecting pipe. A plurality of protruding rings 51 are arranged at intervals on the hollow bellows-shaped connecting pipe 5 , so that the connecting pipe forms a corrugated structure with concavo-convex connected at intervals along the axial direction.

[0012] Diffusion share plate for horizontal diffusion furnace using the present invention, POCl 3 The gas passes through the corrugated passages 6 between the connecting pipes 5 and enters the diffusion furnace. The uniformity of the diffusion process is greatly improved, and the uniformity of the diffusion process can be improved to a fluctuation range of ±3%. , The uniformity between slices is improved to a fluctuation ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com