Iron-contained waste treatment method and equipment adopting same

A treatment method and waste technology, applied in the manufacture of converters, etc., can solve the problems of affecting the cooling effect of coolant, severe carbon-oxygen reaction, dust pollution and other problems, and achieve the effect of convenient process parameter control, simplified steps and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

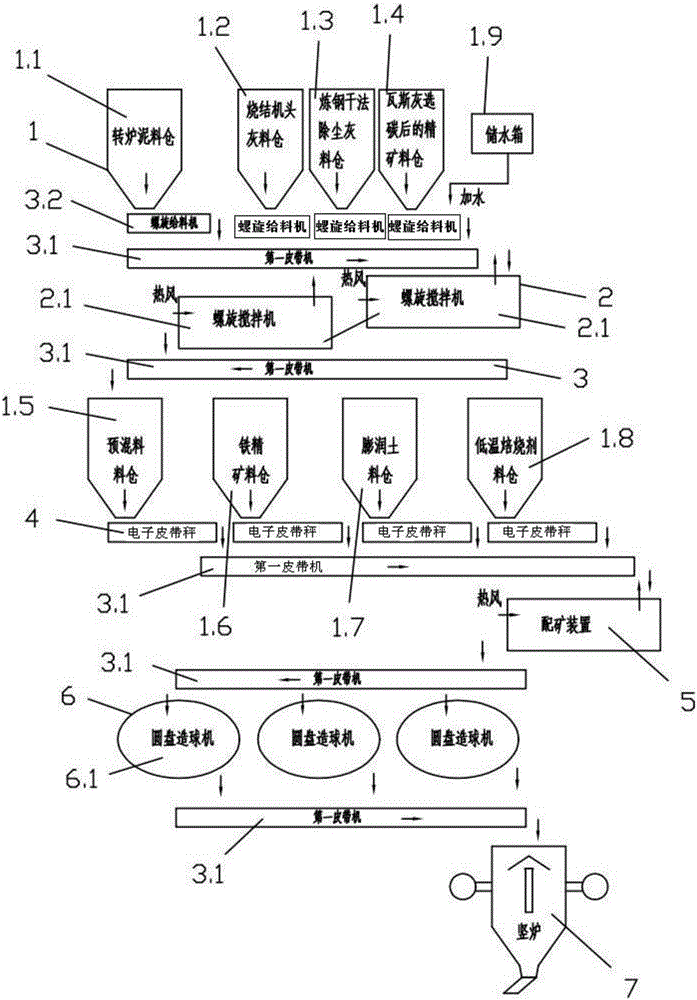

[0045] see figure 1 , the equipment used in a treatment method for iron-containing wastes includes a material storage device 1, a raw material premixing device 2, a conveying device 3, an electronic belt scale 4, an ore blending device 5, a pelletizing device 6 and a shaft furnace 7 (here A shaft furnace with a model of 10 flats is used at the place).

[0046] The material storage device 1 includes a converter mud bin 1.1 for storing converter mud, a sintering head ash bin 1.2 for storing sintering head ash, and a steelmaking dry dust removal bin for storing steelmaking dry dust removal ash. Ash silo 1.3, concentrate silo for storing gas ash and carbon-selected concentrate 1.4, premix silo for storing premixed mixture 1.5, for storing iron concentrate Iron concentrate silo 1.6, pelletizing binder silo 1.7 for storing pelletizing binder, low-temperature roasting agent silo 1.8 for storing low-temperature roasting agent, and water storage tank 1.9 for storing water.

[0047] T...

Embodiment 2-9

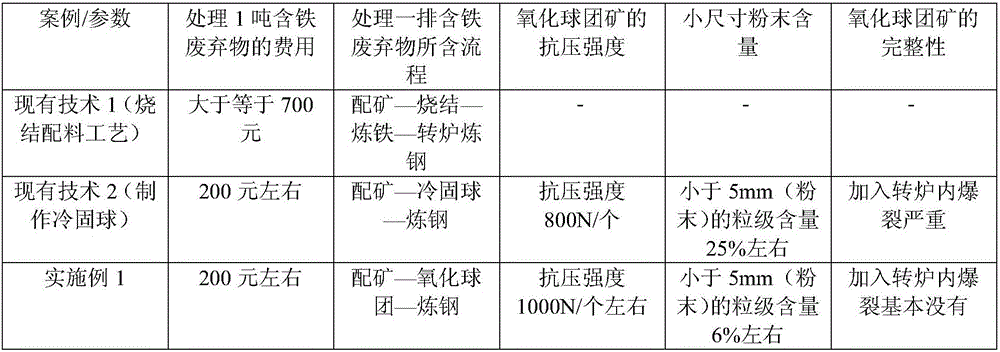

[0071] Embodiment 2-9 investigated the roasting time in the shaft furnace under the condition of 10 minutes, the impact of roasting temperature on the properties of oxidized pellets, other parameters are the same as in Example 1, and the details are as shown in Table 1:

[0072] Parameters and performance statistics of table 1 embodiment 1-embodiment 9

[0073]

[0074] As can be seen from Table 1, the selection of the roasting temperature is most suitable at 1050°C-1130°C, the roasting temperature is too low (such as Example 2-Example 6), and the intensity of the oxidized pellets is low (no more than 500N / piece), It cannot meet the actual needs (the pellets are subjected to friction, collision, extrusion and other mechanical forces in the shaft furnace, and the strength is too low and easy to break, resulting in powder, which affects the air permeability of the shaft furnace production and reduces the yield); the roasting temperature is too high High (such as Example 9), t...

Embodiment 10-13

[0076] Embodiment 10-13 investigated the influence of roasting time on the properties of oxidized pellets when the roasting temperature is constant, and other parameters are the same as in Example 1, and the details are as shown in Table 2:

[0077] Table 2 Embodiment 1 and the parameters and performance statistics of Embodiment 10-13

[0078] Parameters and performance / case Example 10 Example 1 Example 11 Example 12 Example 13 Calcination temperature / ℃ 1050 1050 1050 1050 1050 Roasting time / min 8 10 12 15 16 Roasting strength / N / piece 686 1009 1087 1167 1052

[0079] As can be seen from Table 2, when the roasting temperature is constant, the roasting time is too short (as in Example 10), and the intensity of the oxidized pellets is low (the reaction is insufficient if the time is too short); if the roasting time is too long, the oxidized pellets The strength of the ore does not increase significantly or decreases instead (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com