Female breast simulated polyethylene composite material

A composite material and polyethylene technology, which is applied in the field of composite material processing, can solve the problems affecting the appearance and transparency of the pacifier, the large difference in the texture of the mother's breast, and the difficulty in adjusting the formula of the compound rubber, etc., to achieve broad market promotion potential and excellent mechanics Improvement of performance and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A breast milk simulation polyethylene composite material is composed of the following components in parts by weight:

[0036] 100 parts of linear low density polyethylene, 12 parts of isotactic polypropylene, 8 parts of guar gum, 7 parts of ferric chloride aqueous solution (20% in mass concentration), 0.6 parts of 3,3'-oxindole, 2,4- 0.1 parts of difluorobenzoic acid.

[0037] Its preparation method comprises the following steps:

[0038] Step 1: Weigh raw materials according to the number of parts by mass;

[0039] Step 2: Put polyethylene, polypropylene, and guar gum in graphite molds, put them in a high-temperature furnace, and evacuate to 1×10 - 2 Pa, heated up to 1800°C at a heating rate of 30°C / min, filled with argon, and pressurized to 1×10 7 Pa;

[0040] Step 3: Place 3'-oxindole and 2,4-difluorobenzoic acid in a graphite mold with a filler rod, stir evenly, and keep warm for 12 minutes;

[0041] Step 4: Pour ferric chloride aqueous solution onto the surfa...

Embodiment 2

[0043] A breast milk simulation polyethylene composite material is composed of the following components in parts by weight:

[0044] 150 parts of low-density polyethylene, 17 parts of isotactic polypropylene, 15 parts of guar gum, 10 parts of ferric chloride aqueous solution (22% in mass concentration), 1.2 parts of 3,3'-oxindole, 2,4-di 0.4 parts of fluorobenzoic acid.

[0045] Its preparation method comprises the following steps:

[0046] Step 1: Weigh raw materials according to the number of parts by mass;

[0047] Step 2: Put polyethylene, polypropylene, and guar gum in graphite molds, put them in a high-temperature furnace, and evacuate to 1×10 - 4 Pa, heated up to 2300°C at a heating rate of 50°C / min, filled with argon, and pressurized to 3×10 7 Pa;

[0048] Step 3: Place 3'-oxindole and 2,4-difluorobenzoic acid in a graphite mold with a filler rod, stir evenly, and keep warm for 15 minutes;

[0049] Step 4: Pour ferric chloride aqueous solution onto the surface of...

Embodiment 3

[0050] A breast milk simulation polyethylene composite material is composed of the following components in parts by weight:

[0051]110 parts of linear low density polyethylene, 13 parts of isotactic polypropylene, 9 parts of guar gum, 7 parts of ferric chloride aqueous solution (20% in mass concentration), 0.8 parts of 3,3'-oxindole, 2,4- 0.2 parts of difluorobenzoic acid.

[0052] Its preparation method comprises the following steps:

[0053] Step 1: Weigh raw materials according to the number of parts by mass;

[0054] Step 2: Put polyethylene, polypropylene, and guar gum in graphite molds, put them in a high-temperature furnace, and evacuate to 1×10 - 2 Pa, heated up to 2300°C at a heating rate of 30°C / min, filled with argon, and pressurized to 3×10 7 Pa;

[0055] Step 3: Place 3'-oxindole and 2,4-difluorobenzoic acid in a graphite mold with a filler rod, stir evenly, and keep warm for 12 minutes;

[0056] Step 4: Pour ferric chloride aqueous solution onto the surfac...

PUM

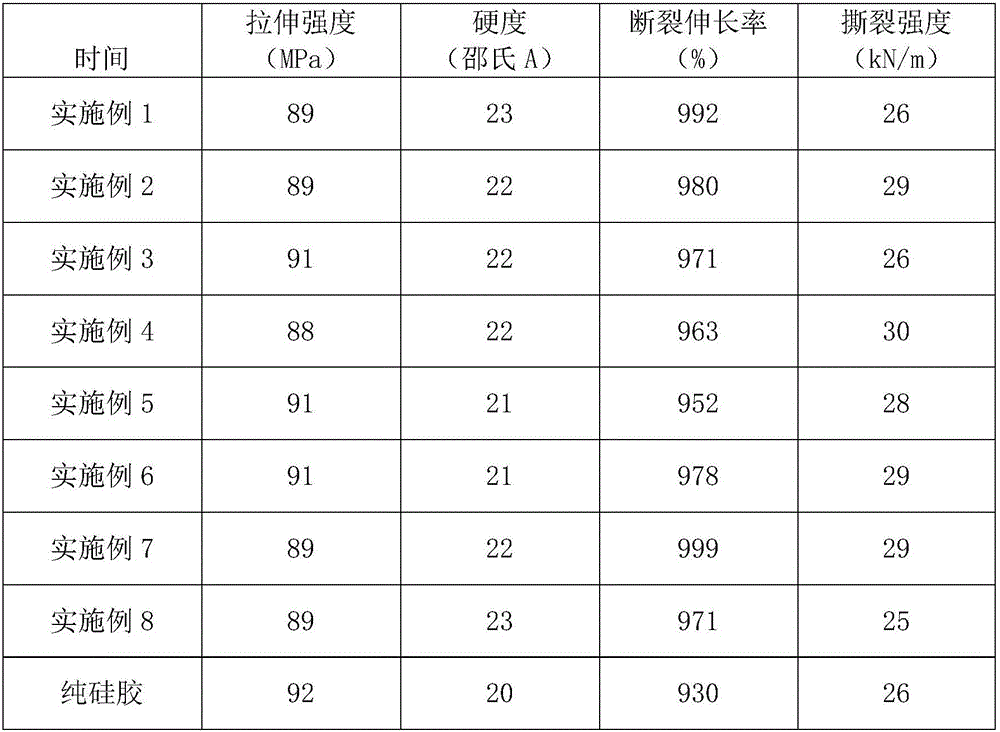

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com