Preparation method and application of microbial flocculant

A technology of microbial flocculant and inoculation amount, which is applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of harsh culture conditions, difficult to settle, difficult to cultivate, etc., to achieve good flocculation effect and not easy to Contaminated, short processing time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The determination of embodiment 1 target bacterial strain

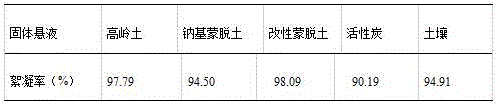

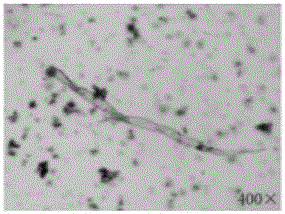

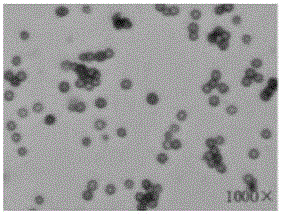

[0030]In this example, 9 kinds of microbial flocculant producing bacteria were screened and isolated from the sludge of the secondary sedimentation tank of a printing and dyeing company in Chongqing, numbered C-1~C-9, and the strains of each number were fermented separately, and the results showed the number The flocculation rate of the fermentation supernatant of the C-6 strain to the kaolin suspension is 95.46%, and the flocculation activity is very stable, which is suitable for use as a microbial flocculant. The morphological identification and ITS rDNA sequence determination of the C-6 strain were carried out, and the BLAST sequence comparison of the NCBI database (see Appendix 1 for the sequence) identified the C-6 strain as Aspergillus niger. The results are shown in Figure 1~4 ( Figure 4 Middle M lane is Marker 2000, NC lane is negative control, 1 lane is C-6 strain), it can be seen that the bacterial...

Embodiment 2

[0031] The fermentation of embodiment 2 Aspergillus niger enzyme

[0032] The fermentation conditions of Aspergillus niger were optimized to make the flocculation effect of the fermented product better. The results showed that the medium solvent for microbial flocculants produced by Aspergillus niger was water, and the solutes included the following components: 15-50 g·L -1 Glucose, 0.1~0.5g·L -1 NaCl, 0.2~1.0 g·L -1 (NH 4 ) 2 SO 4 , 0.5~1.0 g·L -1 Urea, 0.5~1.0 g·L -1 Yeast extract, 0.4~0.6 g·L -1 MgSO 4 ·7H 2 O, 5.0 g L -1 K 2 HPO 4 and 2.0 g L -1 K H 2 PO 4 . The fermentation culture conditions are as follows: inoculate Aspergillus niger with an inoculation amount of 2.0~4.0% (V / V) on the medium with an initial pH of 6.0~9.0, at 30~35°C, 150~200r·min -1 Shaking culture under the conditions of 36 ~ 72h.

[0033] Further research shows that the optimal medium solvent for microbial flocculants produced by Aspergillus niger is water, and the solute includes ...

Embodiment 3

[0035] Example 3 Purification of Fermentation Products

[0036] The fermentation broth was subjected to the following steps (see Figure 5 ) is extracted and purified into a powder product (named MBFC-6). The specific method is to collect the fermentation broth fermented and cultivated for 52 hours under the best fermentation conditions in Example 2, and through 3000r min -1 Centrifuge for 30 minutes to remove bacteria (cells) to obtain the fermentation supernatant, use a rotary evaporator to concentrate the supernatant to 0.5 times the original volume at a temperature of about 45°C, take out the concentrated fermentation supernatant and add 2 times volume of pre-cooled absolute ethanol, and put it in a refrigerator at 4 ℃ for 24 hours, and the solid precipitate was precipitated by 5000 r min -1 Collect by centrifugation for 30 minutes, and dry in vacuum to obtain the crude product of microbial flocculant MBFC-6. Then dissolve the crude microbial flocculant MBFC-6 in distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com