Fork lowering device and fork descent method of electric forklift

A technology of electric forklifts and forks, which is applied in the direction of lifting devices, etc., can solve the problems of forklift vibration, mast impact, electromagnetic proportional valve precision, analog signal uncertainty, etc., to achieve safe and stable descent, avoid impact, and fork Lowering operation is convenient and humanized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

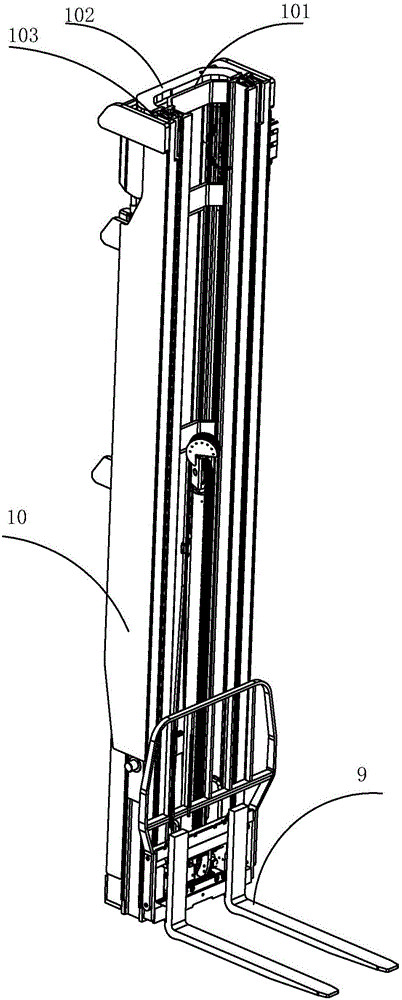

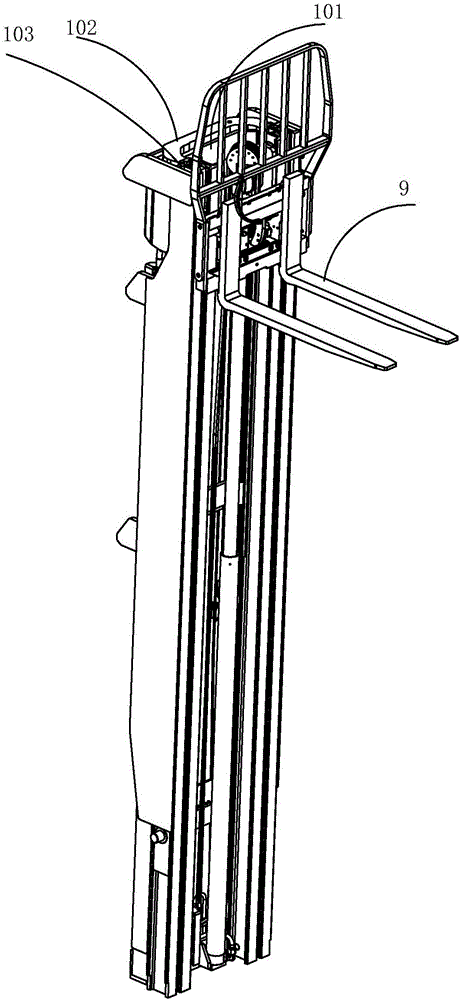

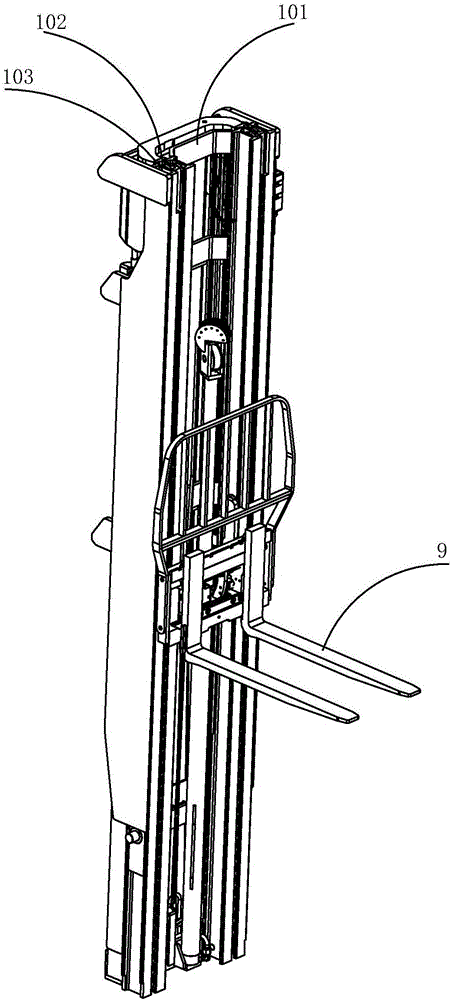

[0045] Embodiment 1: as Figure 5 As shown, the fork lowering device of the electric forklift includes a valve 2 connected to the lifting cylinder 1, a numerical control motor 3, a central processing unit 4 and a height measurement module 5 for detecting the height of the fork, the numerical control motor 3 and the central processing unit 4 connection, the height measurement module 5 is connected with the central processing unit 4, and the central processing unit 4 reads the fork height value detected by the height measurement module 5 and processes it and then sends a signal to control the rotation of the numerical control motor 3, and the numerical control motor 3 controls the rotation of the valve 2 The size of the oil return port controls the oil return speed of the lifting cylinder 1, and the oil return speed of the lifting cylinder 1 directly determines the descending speed of the pallet fork.

[0046] The digitally controlled motor 3 preferably adopts a servo motor or a...

Embodiment 2

[0057] Embodiment 2: The lowering device of the fork of the electric forklift: including the valve 2 communicated with the lifting cylinder 1, the numerical control motor 3, the central processing unit 4, the height measurement module 5 for detecting the height of the fork and the pressure for detecting the load capacity of the fork The sensor 6, the numerically controlled motor 3 are connected to the central processing unit 4, the height measurement module 5 is connected to the central processing unit 4, the pressure sensor 6 is connected to the central processing unit 4, and the central processing unit 4 reads the fork height detected by the height measurement module 5 value and the load value of the fork detected by the pressure sensor 6 and send a signal to control the rotation of the CNC motor 3 after comprehensive processing. The oil return speed directly determines the descending speed of the fork.

[0058] Correspondingly, the fork lowering method of the electric forkl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com