Treating method for recycling waste of breeding industry

A disposal method and waste technology, applied in the direction of solid waste removal, recycling technology, application, etc., can solve the problems of decreased nutritional value, increased energy consumption, poor utilization value of biochar structure, etc., to achieve increased calorific value, Reduce the effect of combustion heating, accelerate diffusion and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Collect pig manure from pig farms and carry out solid-liquid separation to obtain solid separation and separation liquid with a water content of 60%;

[0033] (2) The straw is crushed into particles and mixed with the solid separation to obtain a mixture. The amount of straw particles added is 150 kg of straw particles per ton of the solid separation;

[0034] (3) Heat the mixture to 200°C to evaporate the water in the mixture, reduce the water content to 25%, complete the pre-dehydration treatment, and obtain the dehydration mixture;

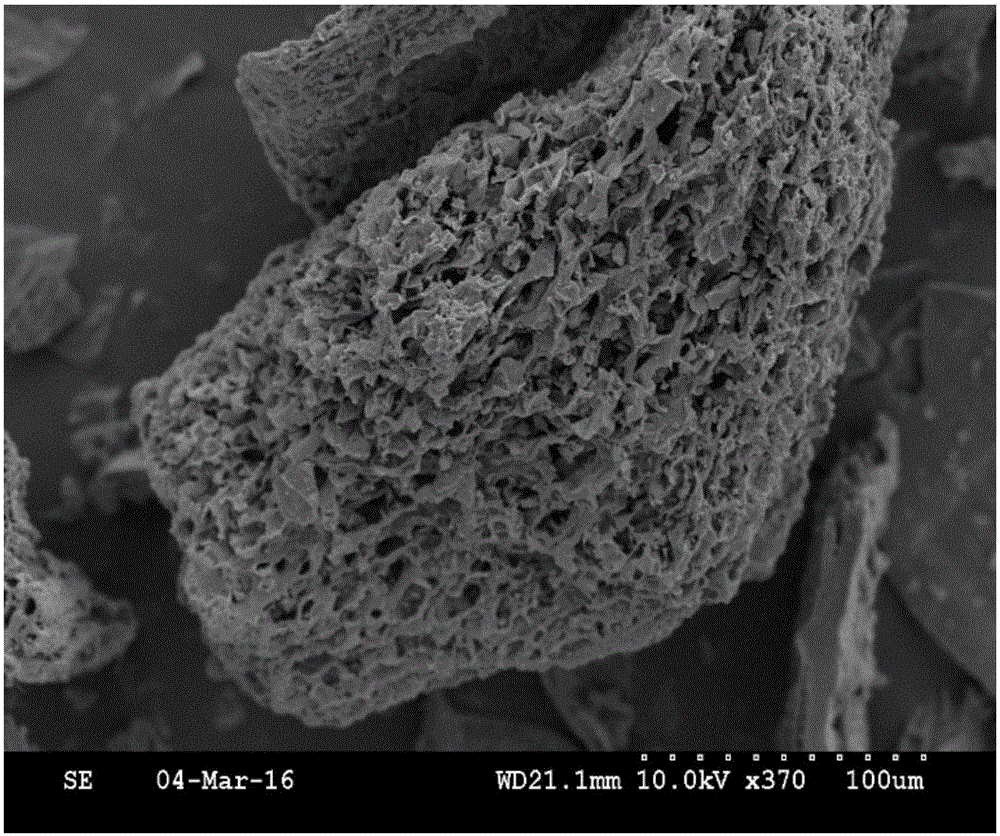

[0035] (4) Heat the dehydration mixture to 500°C and keep it for 6 hours to complete the pyrolysis carbonization process, and isolate the air to cool down to obtain biomass char, such as figure 2 Shown.

[0036] Based on the weight of the solid separation, 180 kg of pig manure charcoal is obtained per ton of the solid separation.

Embodiment 2

[0038] (1) Collect chicken manure from chicken farms and perform solid-liquid separation to obtain solid separation and separation liquid with a water content of 55%;

[0039] (2) The rice husk is crushed into particles and mixed with the solid separation to obtain a mixture, and the amount of rice husk particles added is 200 kg of rice husk particles per ton of the solid separation;

[0040] (3) Heat the mixture to 200°C to evaporate the water in the mixture, reduce the water content to 30%, complete the pre-dehydration treatment, and obtain the dehydration mixture;

[0041] (4) Heating the dehydration mixture to 550°C and keeping it for 6 hours to complete the pyrolysis carbonization process, and isolate the air to cool down to obtain biomass charcoal.

[0042] Based on the weight of the solid separation, 190kg chicken manure charcoal per ton of the solid separation

Embodiment 3

[0044] (1) Collect cow dung from cattle farms and carry out solid-liquid separation to obtain solid separation and separation liquid with a water content of 50%;

[0045] (2) The bark is crushed into particles and mixed with the solid separation to obtain a mixture, and the amount of bark particles added is 180kg of bark particles per ton of the solid separation;

[0046] (3) Heat the mixture to 200°C to evaporate the water in the mixture, reduce the water content to 25%, complete the pre-dehydration treatment, and obtain the dehydration mixture;

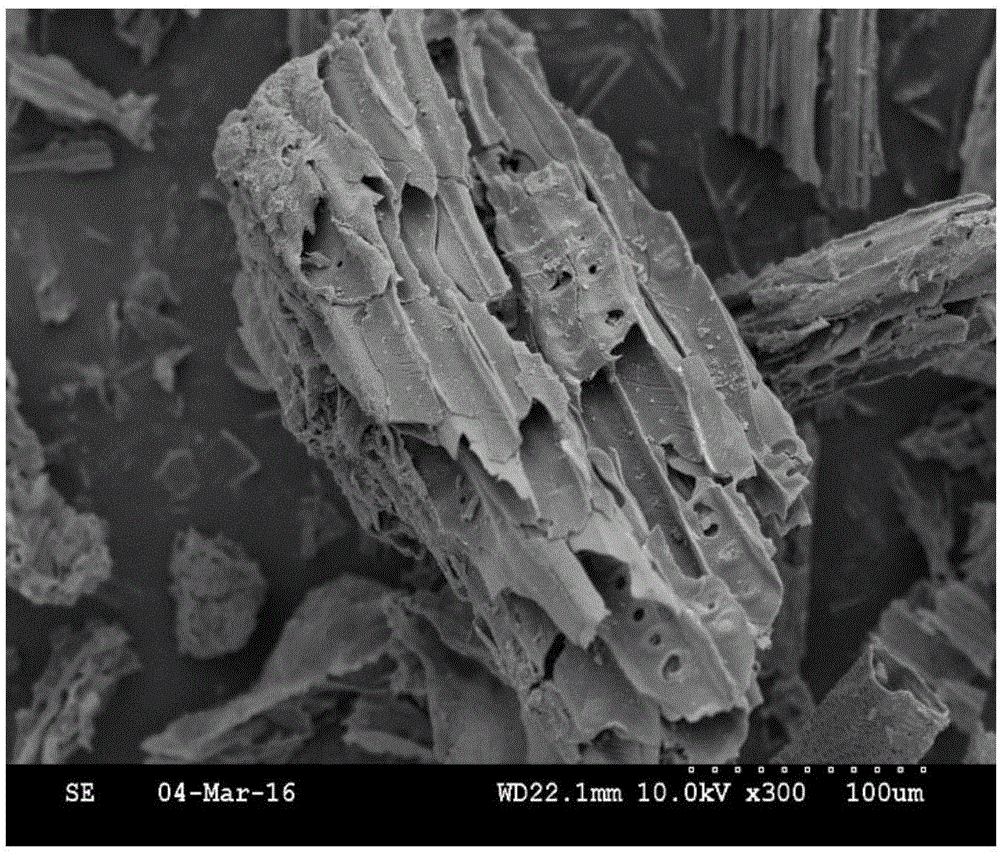

[0047] (4) Heat the dehydration mixture to 500°C and keep it for 7 hours to complete the pyrolysis carbonization process, and isolate the air to cool down to obtain biomass charcoal, such as image 3 Shown.

[0048] Based on the weight of the solid separation, 200 kg of cow manure charcoal is obtained per ton of the solid separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com