Preparation and application of titanium dioxide/activated carbon self-assembled composite

A composite material, titanium dioxide technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

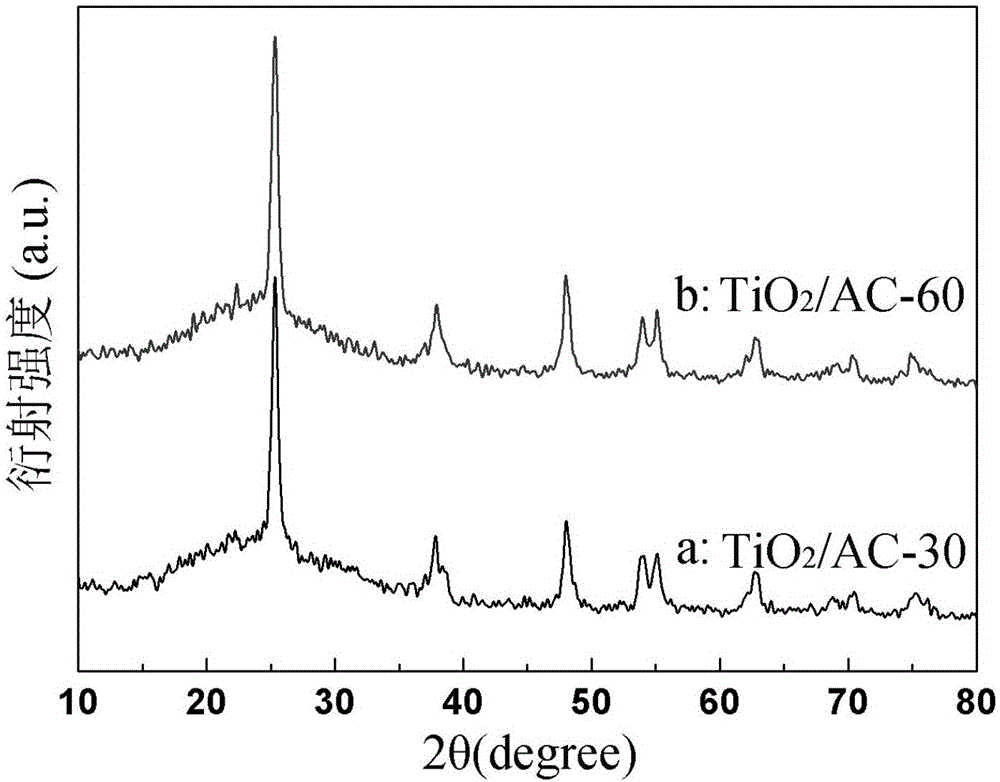

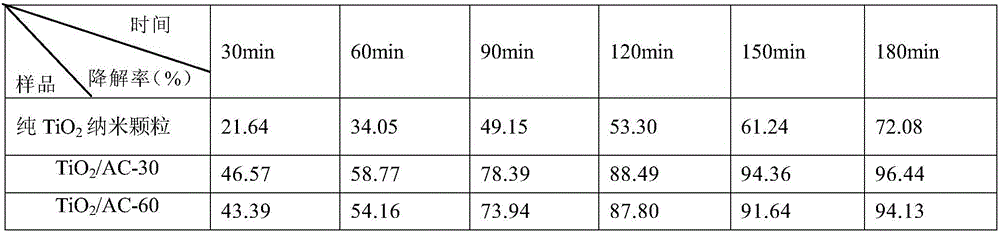

Image

Examples

Embodiment 1

[0032] Step 1, using blue charcoal powder as raw material, prepare blue charcoal powder-based activated carbon by steam activation method.

[0033] Weigh 10-20g of dry blue charcoal powder, put it into the quartz tube furnace, first pass nitrogen into the system to drive out the air, start heating after 10-15 minutes, and heat up at a speed of 10°C / min-15°C / min To the activation temperature of 700 ~ 800 ℃. After activation for 30-90 minutes, stop heating. Cool to room temperature under nitrogen protection. Take out the activated carbon from the furnace and dry it at 100-120°C for 6-8 hours before use.

[0034] Step 2: Add 3-10 mL of tetrabutyl titanate into the ethanol solution, and then stir for 0.5-1 h at a stirring rate of 300-450 r / min to obtain a mixed solution.

[0035] Step 3: Add 0.75-1.0 mL of glacial acetic acid to the above solution, adjust the pH of the solution to 4-6 with concentrated nitric acid, then stir for 1-2 hours at a stirring rate of 400-500 r / min, an...

Embodiment 2

[0044] Step 1, using blue charcoal powder as raw material, prepare blue charcoal powder-based activated carbon by steam activation method.

[0045] Weigh 10g of dry blue charcoal powder, put it into a quartz tube furnace, firstly pass nitrogen into the system to drive out the air, start heating after 15 minutes, and raise the temperature to the activation temperature of 800°C at a rate of 10°C / min. After 30 minutes of activation, stop heating. Cool to room temperature under nitrogen protection. Take out the activated carbon from the furnace and dry it at 120°C for 8 hours for later use;

[0046] Step 2, adding 3.75 mL of tetrabutyl titanate into the ethanol solution, and then stirring for 0.5 h at a stirring rate of 450 r / min to obtain a mixed solution;

[0047] Step 3, add 0.40mL of glacial acetic acid to the above solution, adjust the pH of the solution to 5 with concentrated nitric acid, then stir for 2h at a stirring rate of 400r / min, add 3.0mL of methanol containing 1.0...

Embodiment 3

[0052] Step 1, using blue charcoal powder as raw material, prepare blue charcoal powder-based activated carbon by steam activation method.

[0053] Weigh 10g of dry blue charcoal powder, put it into a quartz tube furnace, firstly pass nitrogen into the system to drive out the air, start heating after 15 minutes, and raise the temperature to the activation temperature of 800°C at a rate of 10°C / min. After 30 minutes of activation, stop heating. Cool to room temperature under nitrogen protection. The activated carbon was taken out from the furnace and dried at 120°C for 8 h before use.

[0054] Step 2, adding 7.5 mL of tetrabutyl titanate into the ethanol solution, and then stirring for 0.5 h at a stirring rate of 450 r / min to obtain a mixed solution;

[0055] Step 3, add 0.75mL of glacial acetic acid to the above solution, adjust the pH of the solution to 5 with concentrated nitric acid, then stir for 2h at a stirring rate of 400r / min, add 5mL of methanol solution containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com