Salt dissolving bucket

A technology of dissolving salt and barrel body, which is applied in the directions of dissolving, dissolving, and water treatment parameter control, etc., can solve the problems of wasting space of salt well pipes, easy hardening of granular salt, and easy carrying of sediment in brine solution, etc., and achieves low cost and small size. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

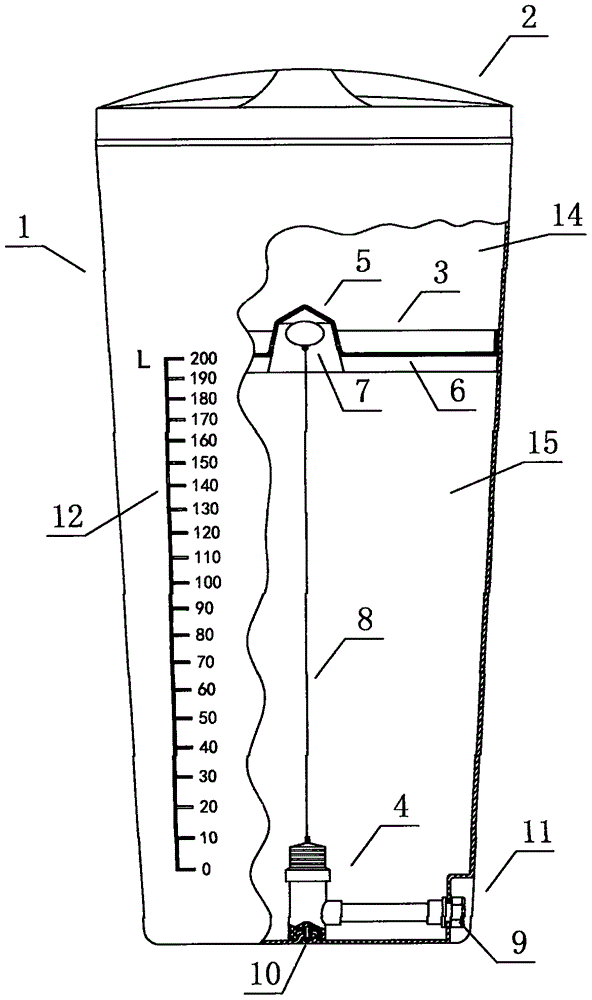

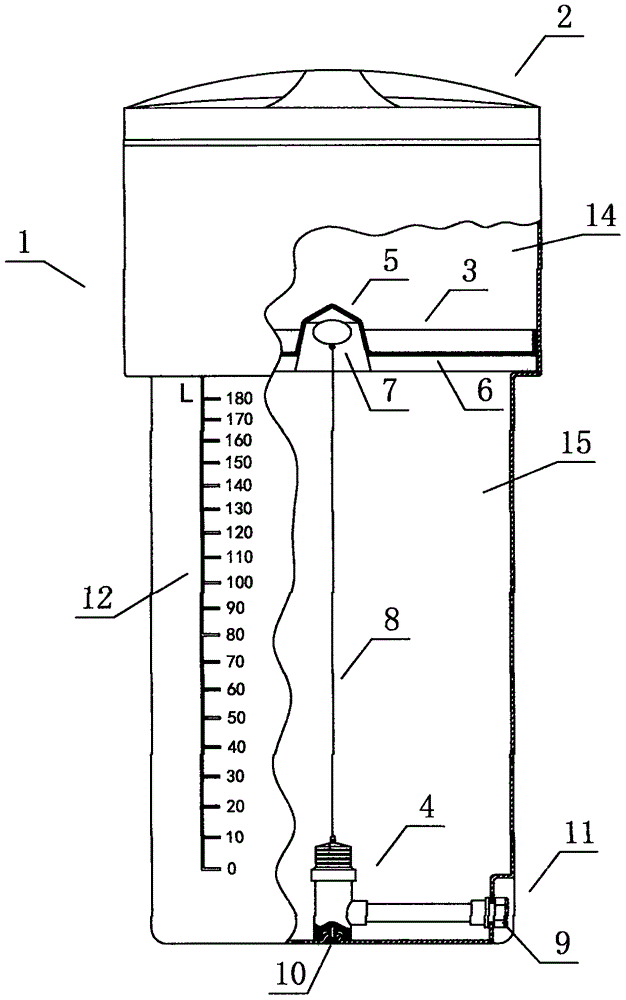

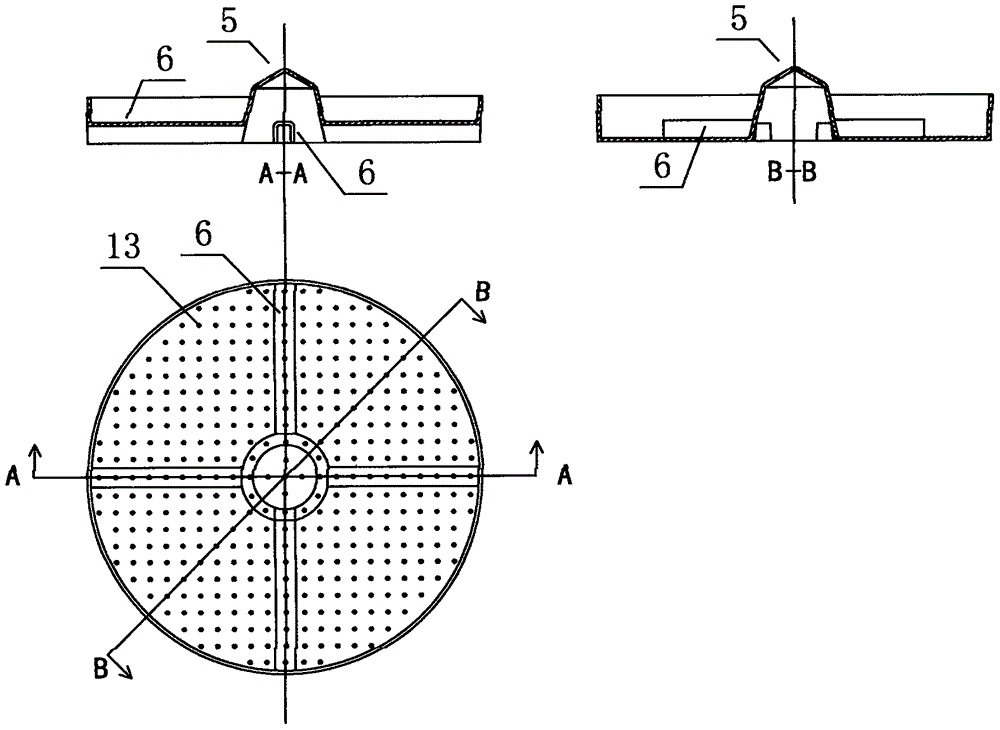

[0011] In the accompanying drawing, the whole molten salt bucket is made of plastic materials and a plastic production process. The barrel body (1), lid, salt plate (3), liquid level control and air check combination valve (4) are produced by mold production respectively; the salt plate (3) is placed on the barrel body (1) with a suitable matching size Inside, for a barrel shaped like a cone, the salt plate (3) is supported by the slope of the cone; for a barrel shaped like a cylinder, the support for the salt plate (3) is realized by the step surfaces of the upper and lower cylinders. support, so that the salt plate (3) separates the barrel body (1) into upper and lower parts, the upper part is the granular salt bin (14), and the lower part is the brine bin (15); Or the convex groove (6) and the float chamber (5) adopt mold to form simultaneously; The cavity (11) on (1) is to rely on the mold and the barrel body (1) to form at the same time; adopt the fastening screw (10) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com