Method for capturing nitric oxide by means of carboxylic acid anion-functionalized ionic liquid

A technology of nitric oxide and ionic liquid, applied in the field of chemistry, can solve the problems of strict equipment, high cost and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a 5ml glass container with an inner diameter of 1 cm, add about 0.70 g (0.0012 mol) of ionic liquid tetradecyl trihexyl phosphobenzoic acid, then place it in a sealed tank with a nitric oxide pressure of 0.1 MPa, and control the absorption temperature to 30 °C, the absorption equilibrium time is 16 hours, and the weighing shows that the absorption capacity of nitric oxide in the ionic liquid is 4.28 mol / mol ionic liquid.

Embodiment 2

[0019] Similar to Example 1, the nitric oxide gas pressure is controlled to be 0.1 MPa, the absorption temperature is 30° C., and the type of ionic liquid is changed. The results of nitric oxide absorption are as follows (Table 1):

[0020] Table 1 Effect of carboxylate anions on nitric oxide capture

[0021]

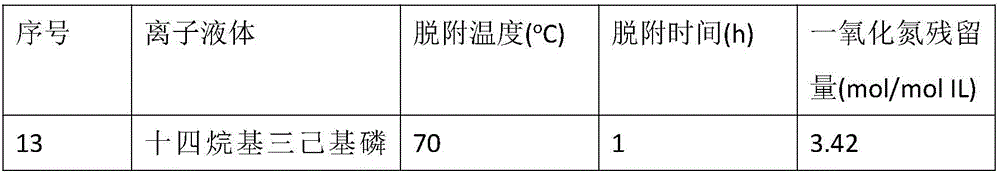

Embodiment 6

[0023] Similar to Example 1, adopt tetradecyltrihexylphosphorus benzoic acid, tetradecyltrihexylphosphorus p-bromobenzoic acid, tetradecyltrihexylphosphorus trichloroacetic acid as absorbent, absorb nitric oxide gas, change Conditions such as absorption temperature, nitric oxide pressure and absorption time, the absorption results are as follows (Table 2):

[0024] Table 2 Effect of different absorption conditions on nitric oxide absorption

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com