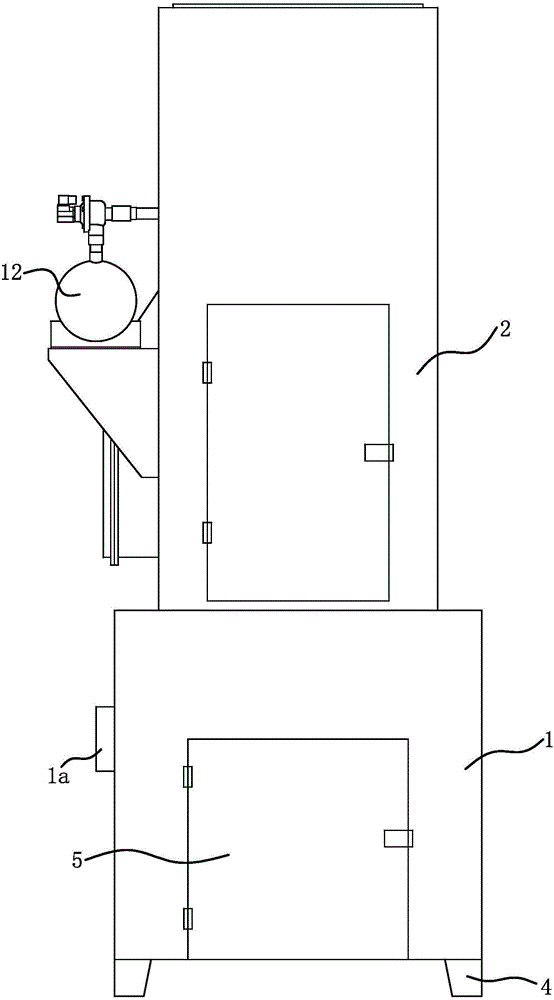

Dust remover

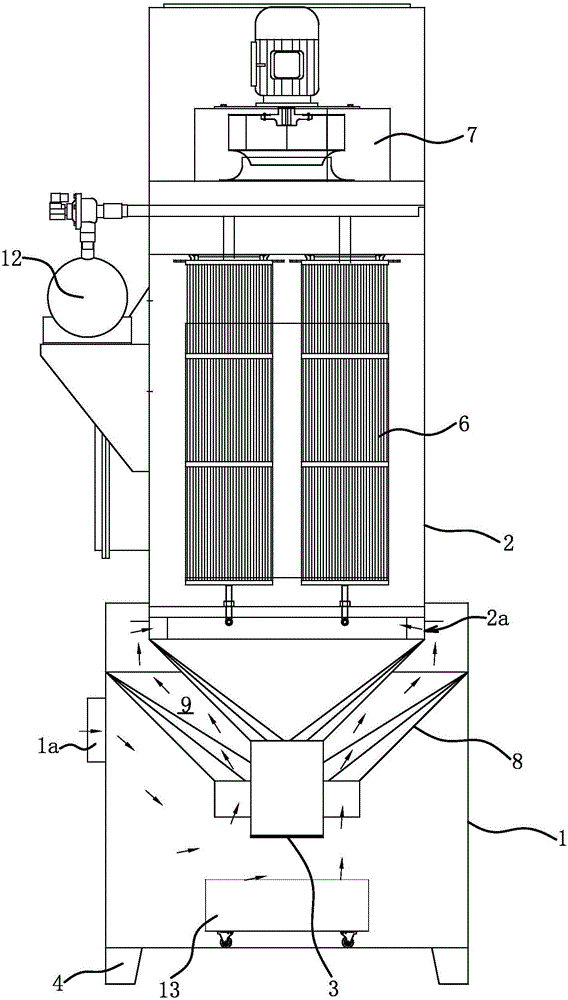

A dust collector and fine dust removal technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of affecting the ventilation effect of the dust collector, the large occupied area of the dust collector, and the large amount of dust processing, and achieve the benefits of The effect of natural sedimentation, reducing the dust removal of the filter element, and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

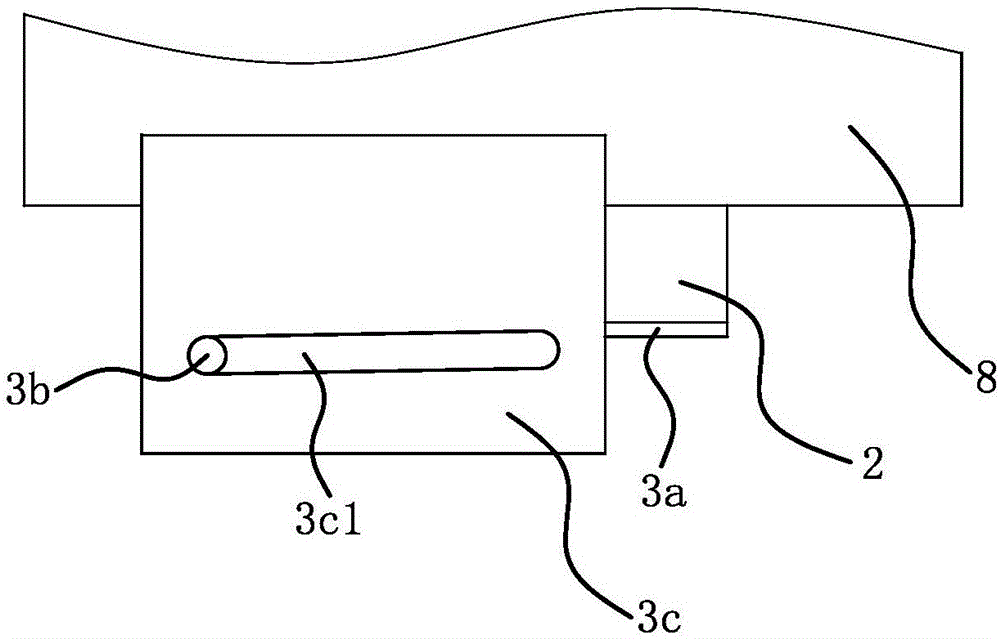

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 5 As shown, the side wall of the fine dust removal box 2 is fixedly connected with an angle iron 10, and the angle iron 10 is placed on the mouth edge of the installation connection port in the pre-dust removal box 1, and the angle iron 10 is connected with the mouth of the installation connection port in the pre-dust removal box 1. A seal is arranged along the pad between them, and the angle iron 10 and the side wall of the pre-dust removal box 1 are fixedly connected by bolts and nuts 11 . The dust collector of this structure is easy to carry, that is, the pre-dust box 1 and the fine dust box 2 are transported separately; they are assembled after reaching the destination. This structure also has the advantage of convenient assem...

Embodiment 3

[0038] The structure and principle of this embodiment are basically the same as those of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the difference is that the ash discharge control valve 3 is an automatic ash unloader.

Embodiment 4

[0040] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities are no longer redundantly described, and only the differences are described. The ventilation channel 9 is provided with a plurality of wind deflectors arranged helically with respect to the axis line of the ventilation pipe 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com