Pressure-control two-way self-cleaning slit-type sewage separation system

A technology of pressure control and separation system, which is applied in the direction of waterway system, separation method, filtration separation, etc. It can solve the problems of difficult to form gaps of equal width, small length, blockage, etc., achieve high separation capacity, increase separation speed, and improve separation quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

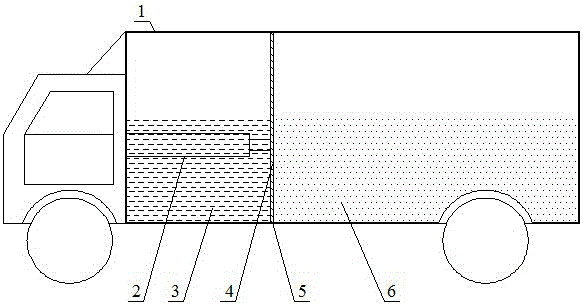

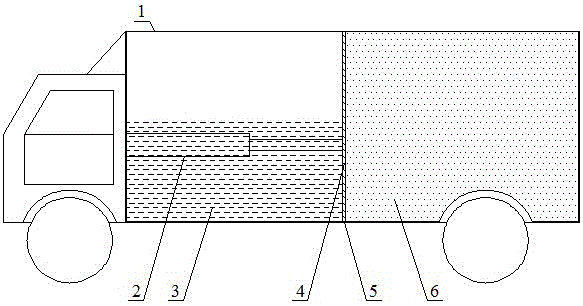

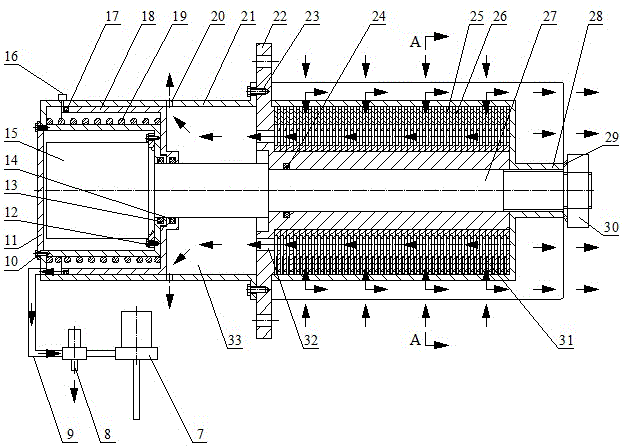

[0040] Sewer dredging vehicle with piston sewage separation system such as figure 1 As shown in ~2, the pressure-controlled two-way self-cleaning gap type sewage separation system and the sewage flow route are as follows image 3 As shown in ~16, the pressure-controlled two-way self-cleaning crevice sewage separation system is installed in the sewage tank of the sewer dredging vehicle and its working status is as follows Figure 17 ~19 shown.

[0041] In the pressure control two-way self-cleaning crevice sewage separation system, the pressure control two-way self-cleaning crevice sewage separation system includes water pump 7, three-way solenoid valve 8, water pipe 9, motor cover bolt 10, motor cover 11, motor bolt 12, motor Shaft seal ring 13, check valve inner seal ring 14, geared motor 15, position switch 16, check valve outer seal ring 17, check valve 18, spring 19, outlet cylinder 21, base 22, outlet cylinder bolt 23, Base sealing ring 24, filter sheet 25, scraper blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com