Intestinal anastomosis ring

A technology for anastomotic rings and intestines, applied in the field of medical devices, can solve problems that need to be further improved, and achieve good mechanical properties, good burst resistance, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An embodiment of the intestinal anastomotic ring of the present invention, the material of the intestinal anastomotic ring is a biodegradable Mg-Zn-Sr alloy; the mass fraction of Zn in the Mg-Zn-Sr alloy is 4%, and the mass fraction of Sr The fraction is 0.1%, and the balance is Mg. The Mg-Zn-Sr alloy is composed of magnesium ingots with a purity of ≥99.9%, zinc ingots with a purity of ≥99.9%, and a Mg-25wt%Sr master alloy in CO 2 and SF 6 In a protective atmosphere (magnesium is easily oxidized and flammable at high temperature, it needs to be smelted in a protective atmosphere), and obtained by melting at 750°C-800°C. The intestinal anastomotic ring is obtained by forging and pressing the above-mentioned Mg-Zn-Sr alloy.

[0042] In vitro corrosion resistance test:

[0043] The artificial simulated body fluid (SBF) was used to soak the specimen for in vitro corrosion test. The artificial simulated body fluid was first prepared, and NaCl and NaHCO were added to the e...

Embodiment 2

[0057] An embodiment of the intestinal anastomotic ring of the present invention, the material of the intestinal anastomotic ring is a biodegradable Mg-Zn-Sr alloy; the mass fraction of Zn in the Mg-Zn-Sr alloy is 4%, and the mass fraction of Sr The fraction is 0.4%, and the balance is Mg. The Mg-Zn-Sr alloy is composed of magnesium ingots with a purity of ≥99.9%, zinc ingots with a purity of ≥99.9%, and a Mg-25wt%Sr master alloy in CO 2 and SF 6 It is obtained by melting at 750°C-800°C in a protective atmosphere. The intestinal anastomotic ring is obtained by forging and pressing the above-mentioned Mg-Zn-Sr alloy. The in vitro corrosion resistance test was carried out by the same method as in Example 1. The specific test results of the immersion weight loss method are shown in Table 2, and the specific test results of the electrochemical corrosion test are shown in Table 3.

Embodiment 3

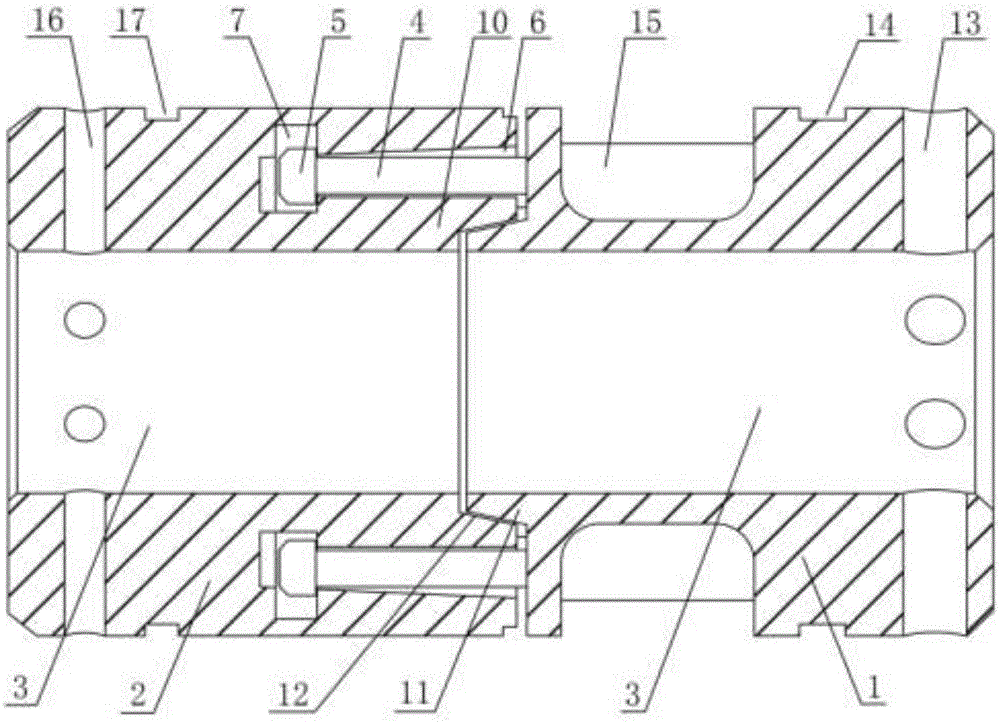

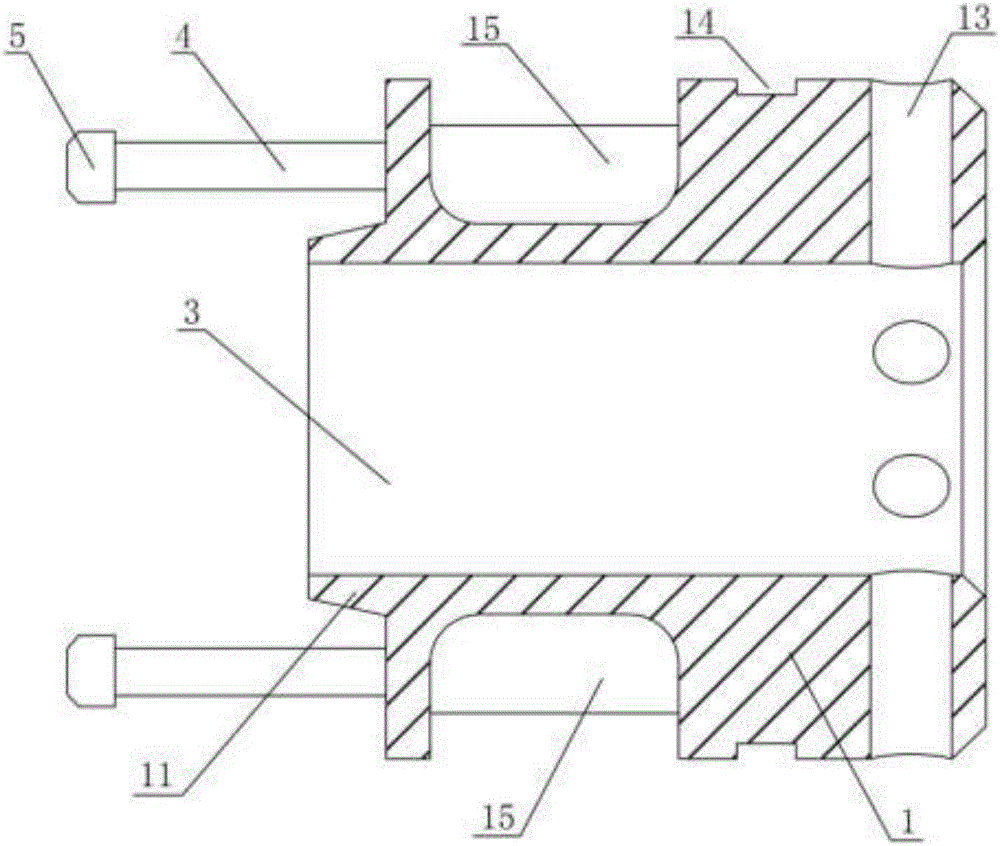

[0070] Such as Figure 1 to Figure 5 As shown, an embodiment of the intestinal anastomotic ring of the present invention, the material of the intestinal anastomotic ring is the Mg-Zn-Sr alloy in the above-mentioned embodiment 1 or embodiment 2, and the intestinal anastomotic ring mainly includes mutually anastomotic First half ring 1 and second half ring 2. When in use, the two sections of intestinal tract to be anastomosed are respectively sleeved on the first half ring 1 and the second half ring 2, and then the first half ring 1 and the second half ring 2 are sleeved and anastomosed to connect the two sections of intestinal tract Docking is carried out so that the tissues of the two intestinal tracts are tightly adhered. The inner circle of the first half-ring 1 and the second half-ring 2 is an intestinal channel 3, and the material in the intestinal tract can be kept unobstructed through the intestinal channel 3 after the first half-ring 1 and the second half-ring 2 are an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com