Preparation method and application of lithium-rich layered oxide cathode material

A technology of positive electrode materials and oxides, which is applied in the field of preparation of lithium-rich layered oxide positive electrode materials, can solve undiscovered problems, achieve the effects of reducing oxygen precipitation, improving cycle capacity retention, and high process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

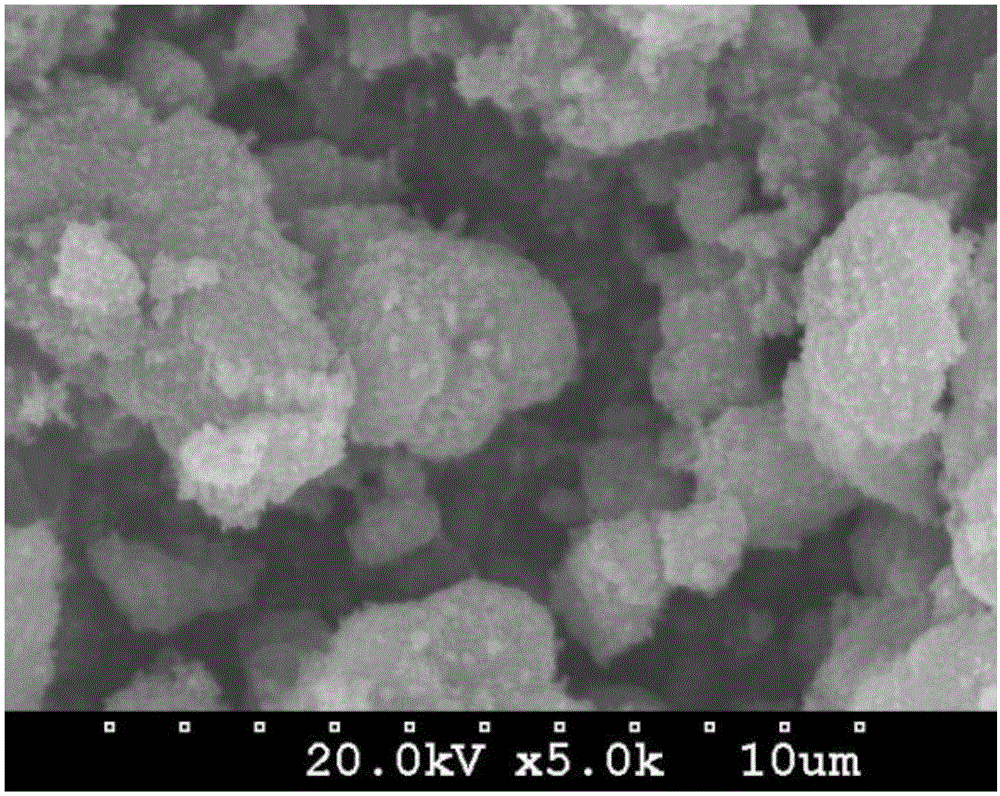

Image

Examples

Embodiment 1

[0029] A preparation method of a lithium-rich layered oxide positive electrode material, the chemical molecular formula of the lithium-rich layered oxide positive electrode material is Li[Li 0.28 Ni 0.06 Fe 0.04 mn 0.62 ]O 2 (x=1 / 12, M=Fe, y=0.02), its preparation method step is as follows:

[0030] 1) Weigh 87.14g MnSO 4 ·H 2 O and 16.16g Fe(NO 3 ) 3 9H 2 O preparation metal ion concentration is the solution of 1mol / L;

[0031] 2) under continuous stirring condition, slowly add the mixed solution of ammoniacal liquor and sodium carbonate in above-mentioned solution, ammoniacal liquor concentration is 0.2mol / L in the mixed solution, and sodium carbonate concentration is 2mol / L, to control reaction solution pH value is 10, A precipitation reaction was performed, and the precipitate was filtered, washed, and dried to obtain Fe-doped MnCO 3 Material;

[0032] 3) Weigh 41.05g Li 2 CO 3 , and combine it with the Fe-doped MnCO obtained in step 2) 3 The materials were m...

Embodiment 2

[0039] A preparation method of a lithium-rich layered oxide positive electrode material, the chemical molecular formula of the lithium-rich layered oxide positive electrode material is Li[Li 0.2 Ni 0.1 co 0.2 mn 0.5 ]O 2 (x=1 / 5, M=Co, y=0.1), its preparation method step is as follows:

[0040] 1) Weigh 27.58g LiNO respectively 3 ·H 2 O,22.99gMnCO 3 and 16.05gCo 3 o 4 ,well mixed;

[0041] 2) The mixture obtained in step 1) is placed in a muffle furnace for calcination, the calcination temperature is 750°C, and the calcination time is 5h to obtain Co-doped Li 2 MnO 3 Material;

[0042] 3) Preparation of 42.78g NiCl·6H 2 O and 50.71 g MnSO 4 4H 2 O mixed solution, the total concentration of metal ions is 2.5mol / L;

[0043] 4) under continuous stirring condition, slowly add the mixed solution of ammoniacal liquor and sodium hydroxide in the solution of step 3) gained, in the mixed solution, the concentration of ammoniacal liquor is 0.3mol / L, and the concentration o...

Embodiment 3

[0049] A preparation method of a lithium-rich layered oxide positive electrode material, the chemical molecular formula of the lithium-rich layered oxide positive electrode material is Li[Li 0.11 Ni 0.28 al 0.1 mn 0.51 ]O 2 (x=1 / 3, M=Al, y=0.05), its preparation method step is as follows:

[0050] 1) Weigh 9.32g LiOH, 10.87gMn(OH) respectively 2 and 37.51gAl(NO 3 ) 3 9H 2 O, mix well;

[0051] 2) The mixture obtained in step 1) is placed in a muffle furnace for calcination, the calcination temperature is 550°C, and the calcination time is 55h to obtain Al-doped Li 2 MnO 3 Material;

[0052] 3) the Al-doped Li obtained in step 2) 2 MnO 3 Material with 24.63g Li 2 CO 3 , 10.21gNiO and 44.06gMnCO3 mix homogeneously, obtain mixture;

[0053] 4) The mixture obtained in step 3) was placed in a muffle furnace for calcination, the calcination temperature was 700° C., and the calcination time was 15 hours to obtain 86.85 g of lithium-rich layered oxide cathode material Li[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com