Method of acquiring flexible ferroelectric thin film capacitor nondestructively

A ferroelectric thin film, non-destructive technology, applied in the direction of capacitors, circuits, electrical components, etc., can solve the problems of high equipment and process requirements, time and capital investment, and lack of electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

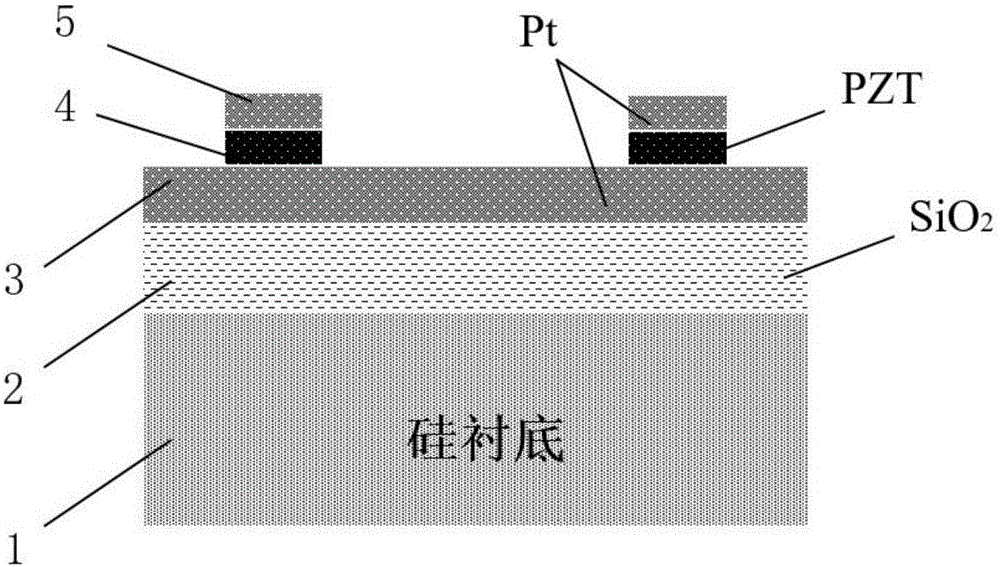

[0027] A kind of PZT structural feature of rigid silicon substrate comprises: silicon substrate 1, epitaxial buffer silicon dioxide (SiO 2 ) layer 2, lower electrode 3, PZT4, upper electrode 5, such as figure 1 .

[0028] Before grinding, measure the hysteresis loop of the sample in advance to compare the subsequent measurement results. The instrument used is a ferroelectric performance tester. The test conditions are: voltage 40V, frequency 1kHz, and test waveform is triangular wave.

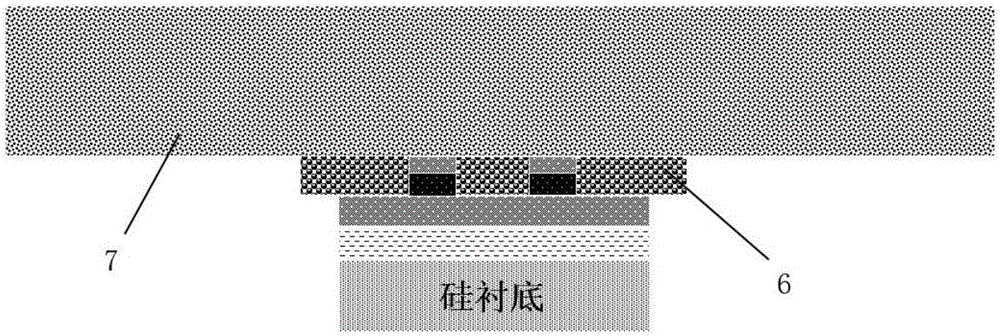

[0029] First, heat up the heating platform, put the small glass piece 7 on the heating platform, and at the same time place a small piece of industrial wax 6 at the center of the small glass piece 7, when the industrial wax 6 is completely melted (about 80 ℃ ) clamp the sample with tweezers, at this time the sample is rigid, and at the same time the silicon substrate 1 is facing up, placed in the center of the small glass piece 7, so that it is fully in contact with the industrial wax 6, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com