An electrically controlled terahertz polarizer based on a graphene grid strip structure and its application method

A technology of graphene and polarizers, which is applied in the field of terahertz band devices, can solve the problems of non-tunable polarizers, narrow spectral width range, and inconvenient integration, and achieve the effects of wide spectral width range, good compatibility, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

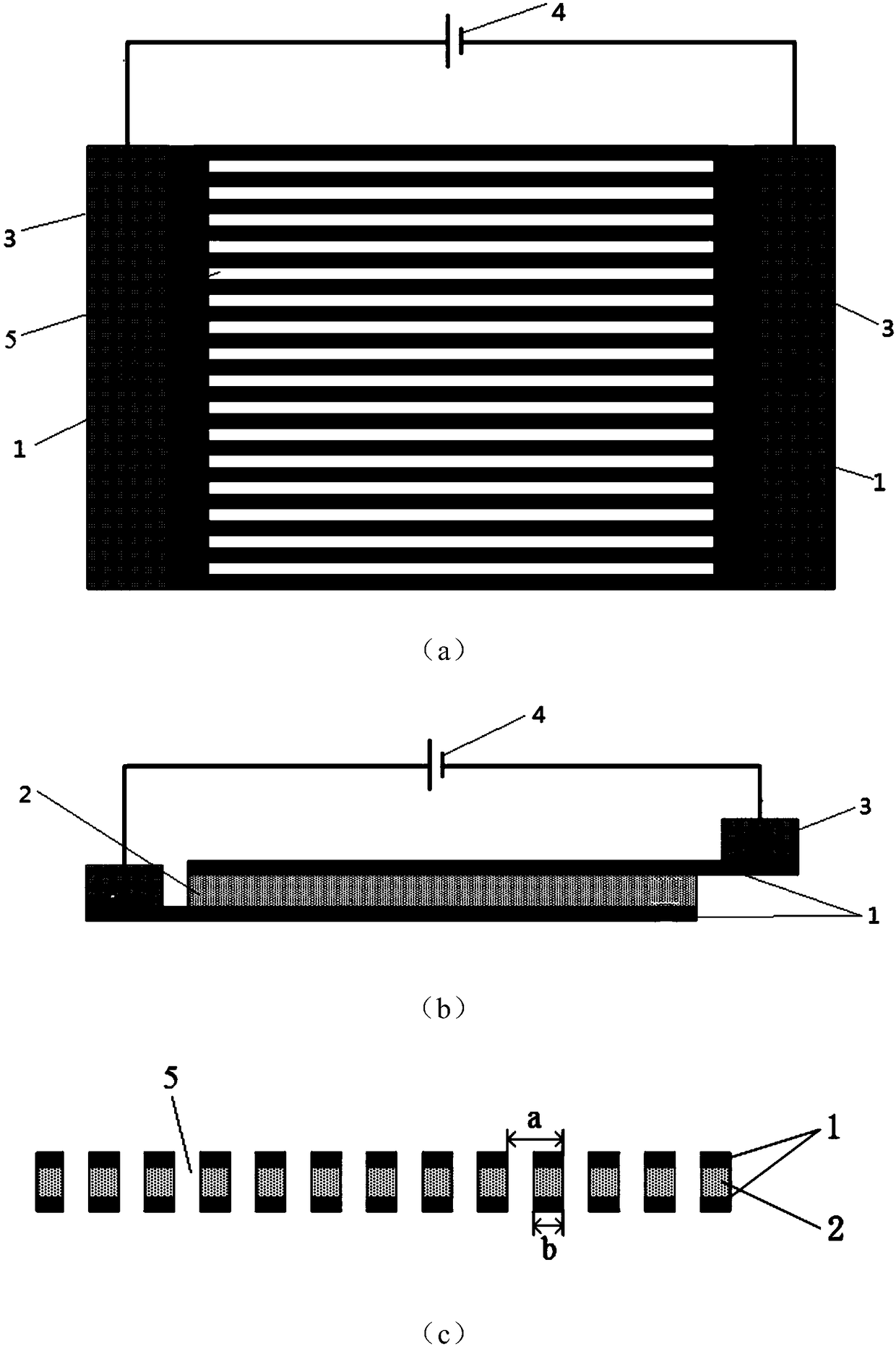

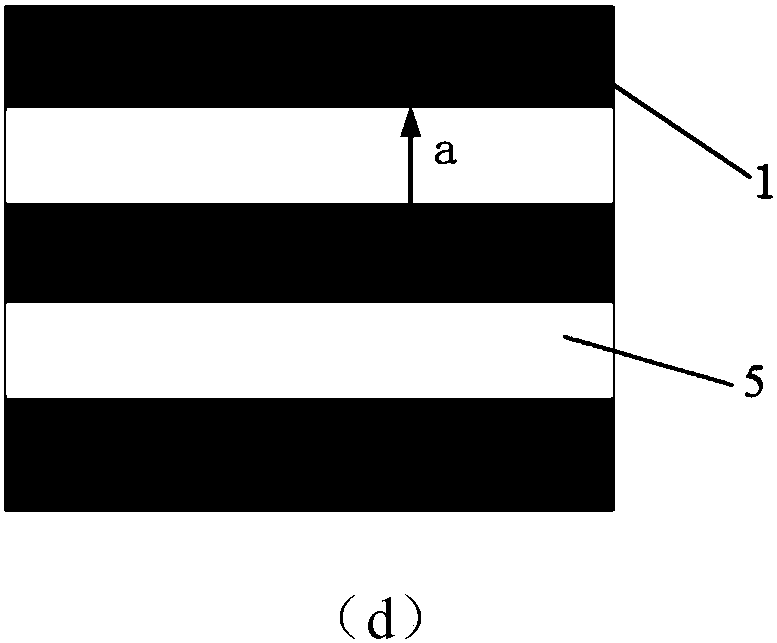

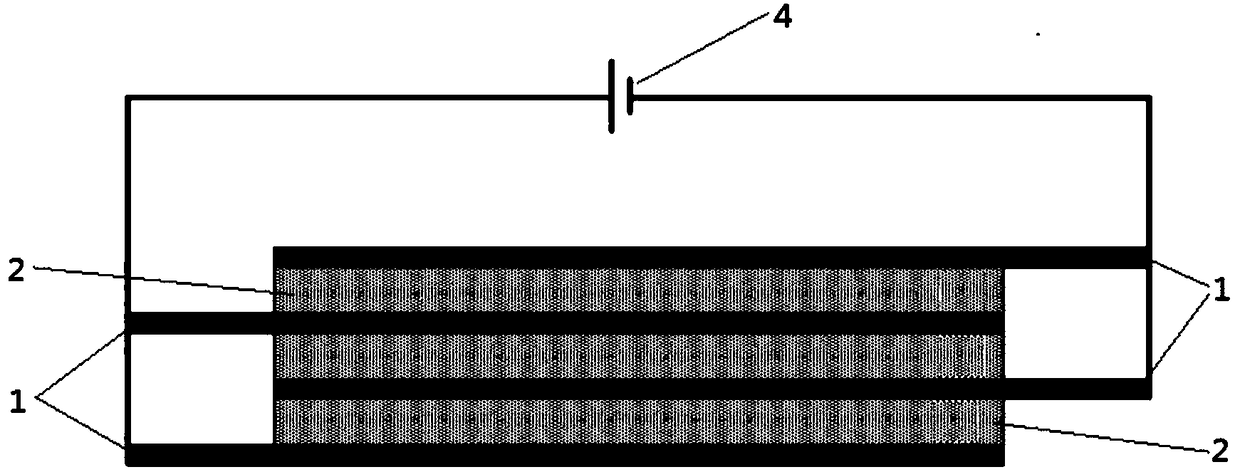

[0036]This embodiment provides a graphene-based electronically controlled terahertz polarizer, including at least two graphene layers 1, and a dielectric layer 2 is provided between every two adjacent graphene layers 1, and each layer of graphite Holes 5 are provided on the alkene layer 1, and holes 5 are also provided on each of the dielectric layers 2. The holes on the graphene layer 1 coincide with the holes on the dielectric layer 2, and each layer of graphene is There are multiple holes 5 on the layer 1, the number of holes on each layer of dielectric layer 2 is the same as the number of holes on each layer of graphene layer 1, and the number of holes on each layer of graphene layer 1 and The holes on each dielectric layer 2 are distributed in an array;

[0037] The graphene layers 1 of the even layers are connected together on one electrode 3, the graphene layers 1 of the odd layers are connected on the other electrode 3, and voltage regulation can be realized by applyin...

Embodiment 2

[0039] A preparation method of the polarizer described in Example 1, the polarizer is processed on the substrate or the terahertz element before use, and each layer structure is prepared layer by layer on the terahertz element or the substrate in order from bottom to top, including at least Two layers of graphene layers, a dielectric layer between every two adjacent graphene layers, an electrode connected to the even-numbered graphene layers and another electrode connected to the odd-numbered graphene layers, between the two electrodes Apply voltage to ensure that each dielectric layer completely separates adjacent graphite layers;

[0040] The preparation of the graphene layer adopts chemical vapor phase method, mechanical stripping method, epitaxial growth method or redox method; the preparation of the dielectric layer adopts vacuum evaporation method, spin coating method or chemical vapor deposition method; the preparation of the electrode adopts vacuum evaporation method. ...

Embodiment 3

[0042] A method for using the polarizer described in Embodiment 1, for a polarizer with a fixed number of layers, a constant voltage is applied to an electrode connected to an even-numbered graphene layer and another electrode connected to an odd-numbered graphene layer, and the As the voltage increases, the amplitude of the transmitted terahertz pulse whose polarization direction is parallel to the grid strip is observed to determine the control range. By changing the voltage, the polarization degree of the transmitted terahertz wave can be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com