Shell-and-plate blast furnace evaporation air cooling system using soft water closed recirculation cooling system and plate scale treatment method thereof

A circulating cooling system, soft water sealing technology, applied in water shower coolers, direct contact heat exchangers, energy industry, etc., can solve problems such as incomplete treatment of board scale, short service life of fan motors, etc., to achieve greater Continuous operation time and service life, reduction of total installed capacity and production cost, and thorough treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

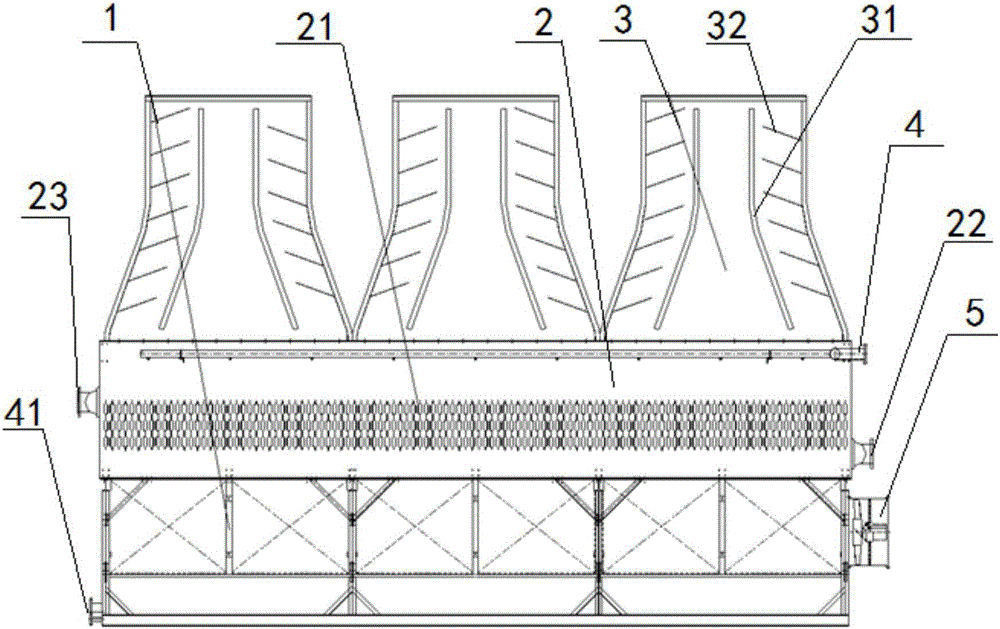

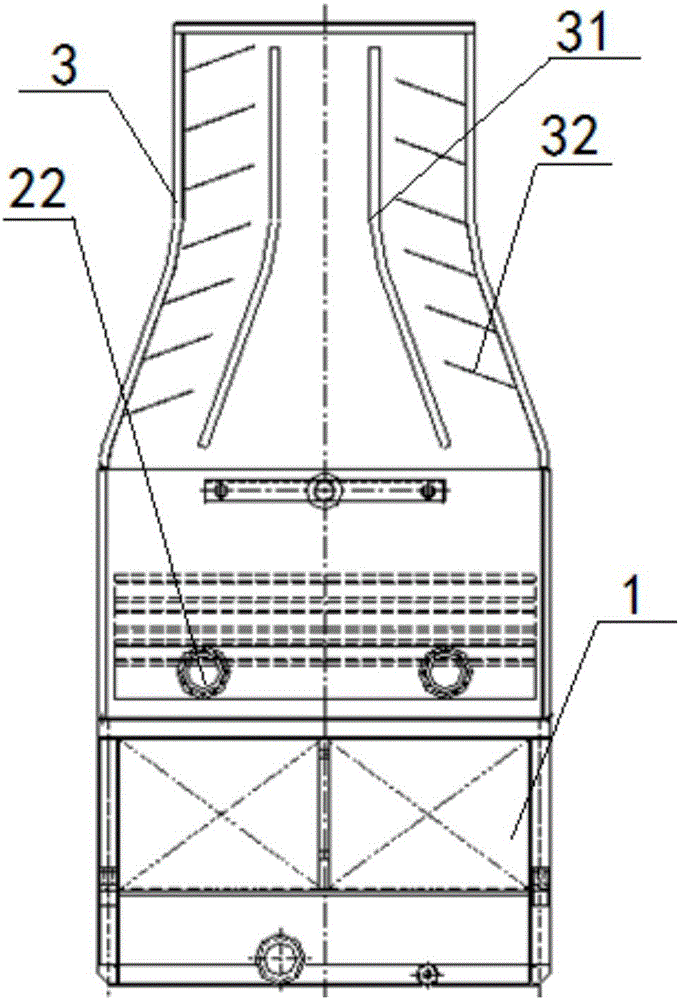

[0047] A steel plant 2 4000m 3 Blast furnace staves and hot blast stoves adopt a soft water closed circulation cooling system. The two blast furnaces use a total of 38 plate-shell blast furnace evaporative air cooling systems using a soft water closed circulation cooling system in this embodiment, which are operated in parallel. The soft water closed circulation cooling system used in this embodiment The systematic plate-and-shell type blast furnace evaporative air cooling system includes a base 1 of 3m*9m, a shell 2 fixedly connected to each other directly above the base 1, and a vertically layered cooling plate bundle set 21 fixedly installed inside the shell 2, The cooling plate bundle 21 communicates with the soft water system of the blast furnace through the cooling water inlet 23 and the cooling water outlet 22. The cooling water inlet 23 and the cooling water outlet 22 are opposite to each other on both sides of the cooling plate bundle 21, and the cooling water inlet is...

Embodiment 2

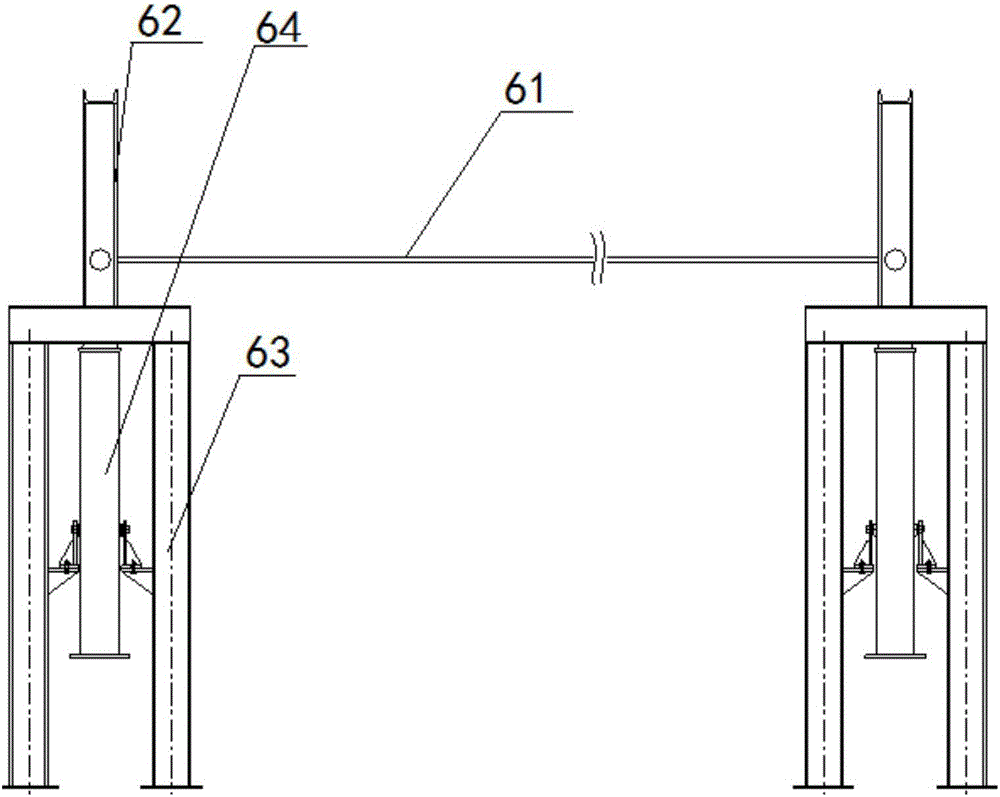

[0050] The plate-shell type blast furnace evaporative air-cooling system adopting soft water closed cycle cooling system in this embodiment has the same basic structure as that in Embodiment 1, the difference and improvement are: there are 5 hyperbolic cooling towers with a height of 4 meters, and the outer walls are evenly and fixedly distributed There are reinforcing ribs 31 to fasten and stabilize the cooling tower, and the inner wall is evenly fixed with water retaining sheets 32, which condense part of the water and drip back to the system to prevent excessive water discharge from causing waste of water resources. The water baffle 32 is ring-shaped, and is in the shape of a trumpet that is inclined downward and open, which does not affect the formation of wind eddies, and effectively prevents the excessive discharge of water. like image 3 , 4 As shown, a descaling device 6 is also included, and the descaling device 6 includes two brackets 63, the upper platform of each ...

Embodiment 3

[0062] The plate and shell type blast furnace evaporative air cooling system adopting soft water closed circulation cooling system in this embodiment has the same basic structure and descaling method as in embodiment 2, the differences and improvements are as follows: figure 1 , 2 , shown in 5 and 6, the hyperbolic cooling tower has 3, and height is 6 meters, also comprises the blower fan 5 that is fixed on the side of base 1, and described base 1 is the semi-closed shape of top opening, and the bottom is a spray pool, and On the opposite side of the blower 5, there is a spray outlet 41 connected to the spray device 4 through a pipeline. The spray device 4 is arranged on the inner side of the upper part of the housing 1, and a spray port is evenly opened downward, and the spray port has no dead angle. Covered directly above the cooling plate bundle set 21; the blower is placed under the type and blows inward, without hot and humid air eroding the insulation of the motor and ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com