Full-automatic starting system and method for sintering waste heat recycling and sintering draught fan combined unit

A waste heat recovery and combined unit technology, applied in the direction of machines/engines, waste heat treatment, furnace components, etc., can solve the problems of large investment costs, achieve remarkable results, reduce workload and the incidence of misoperation, and improve advanced and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Firstly, through the research on the process system of sintering waste heat recovery and sintering fan combined drive unit, and the research on the steam characteristics of the boiler system, it analyzes the difficulties faced by the fully automatic start-up control of the unit, such as the lack of reference engineering experience and specific implementation methods, and proposes sintering waste heat A method for fully automatic start-up control of a recovery and sintering fan combined drive unit.

[0029] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

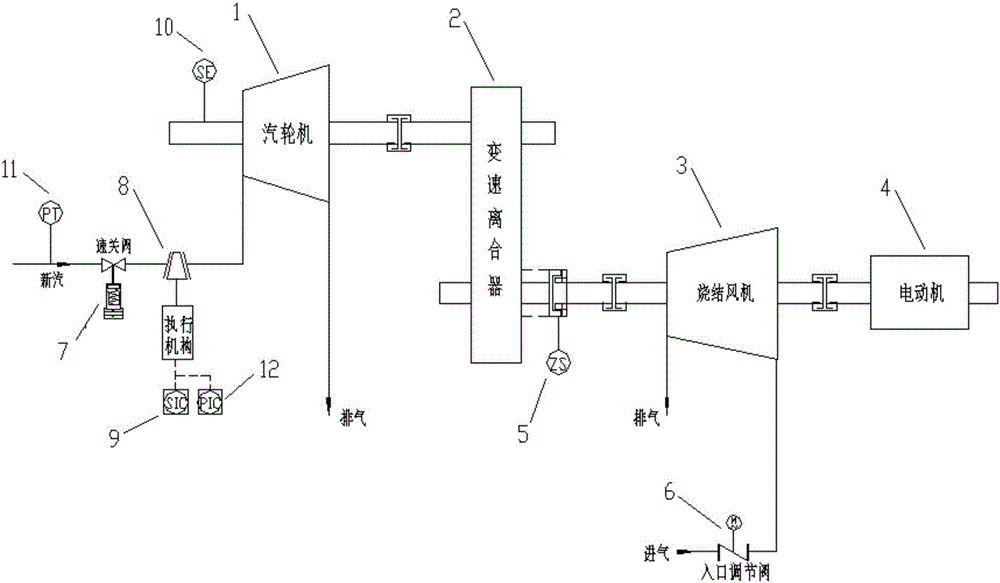

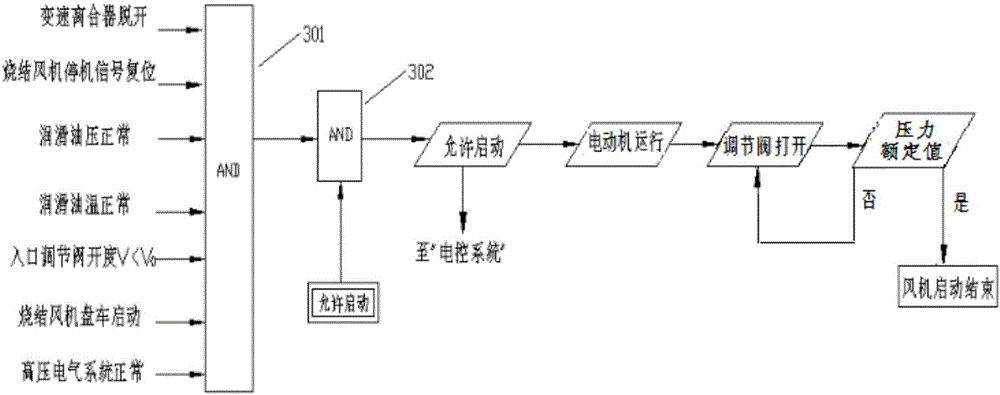

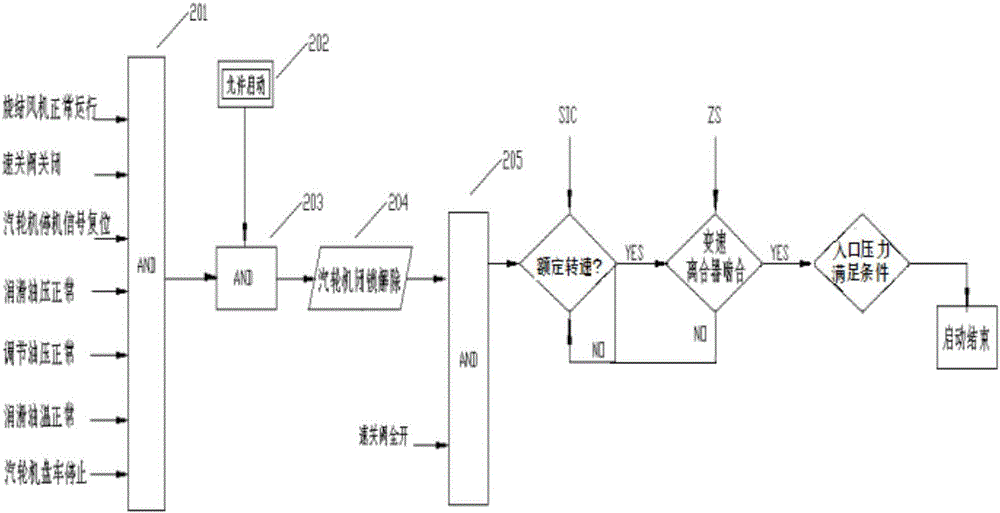

[0030] refer to figure 1 , the sintering waste heat recovery and sintering fan combined unit automatic starting system of the present invention includes a sintering fan 3 with double output shafts, a motor 4, a variable speed clutch 2 and a steam turbine 1, and one output shaft end of the sintering fan 3 is the same as the motor 4 Shaft conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com