Treatment method of electroplating wastewater

A technology of electroplating wastewater and treatment methods, applied in the field of water treatment, can solve problems such as waste of social wealth, and achieve the effects of solving pollution, high operating profit margins, and simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

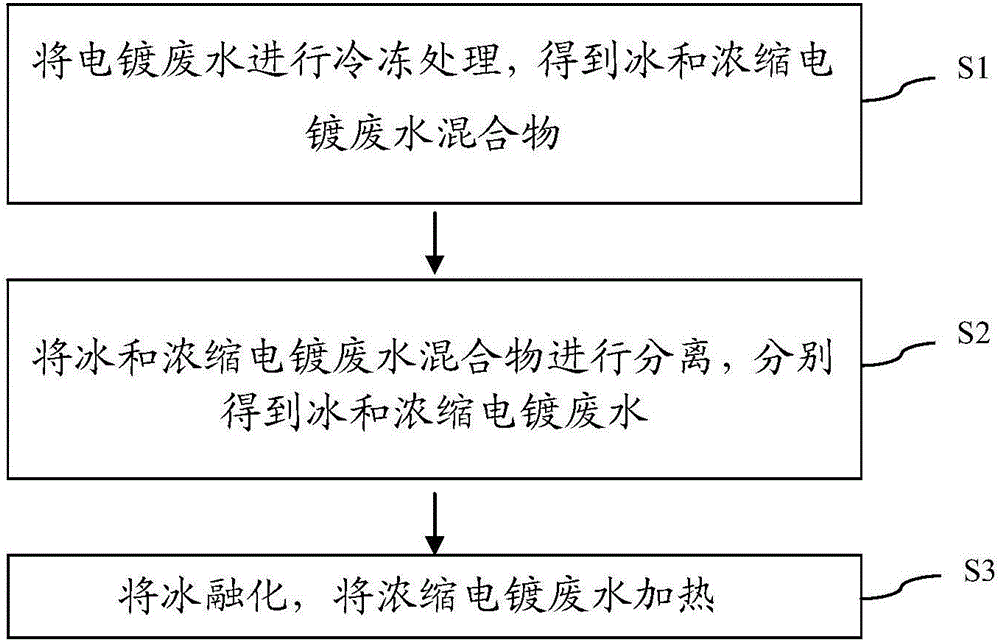

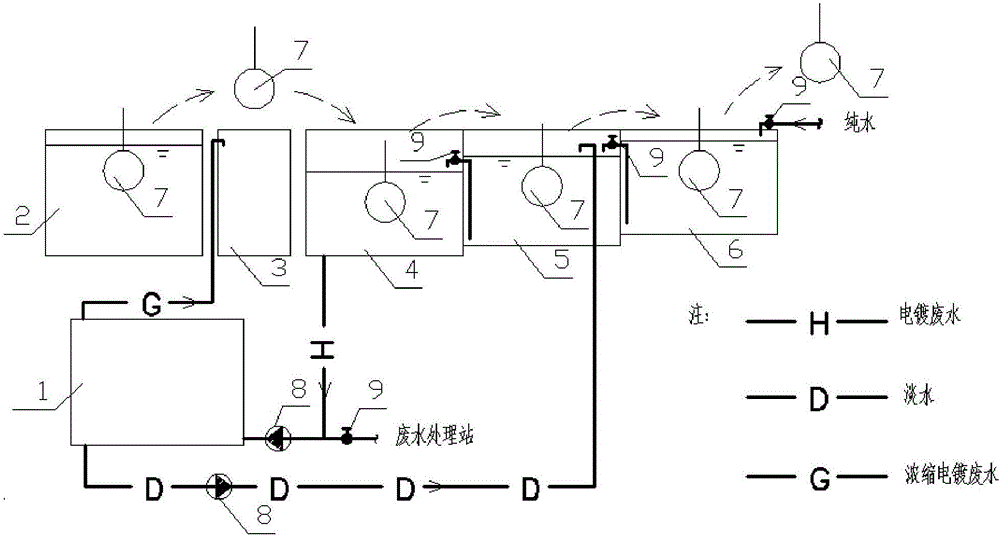

[0030] see figure 1 , is a schematic flow sheet of an embodiment of the treatment method of electroplating wastewater according to the present invention, the method may further comprise the steps:

[0031] S1: Freeze the electroplating wastewater to obtain a mixture of ice and concentrated electroplating wastewater

[0032] During the freezing process of the solution, some salt will be mixed between the ice crystals in the form of salt cells. As time goes by, the salt will form brine channels between the ice bodies, and the residual high-concentration brine will slowly discharge out along the brine channels. . The thinner the ice layer, the shorter the brine channel, the easier the solute is discharged, and the purer the ice. And the smaller the ice crystal volume, the higher the heat transfer efficiency and the shorter the ice melting time. But at the same time, the smaller the ice crystal volume, the larger the surface area, the more solution attached to the surface, and ...

Embodiment 2

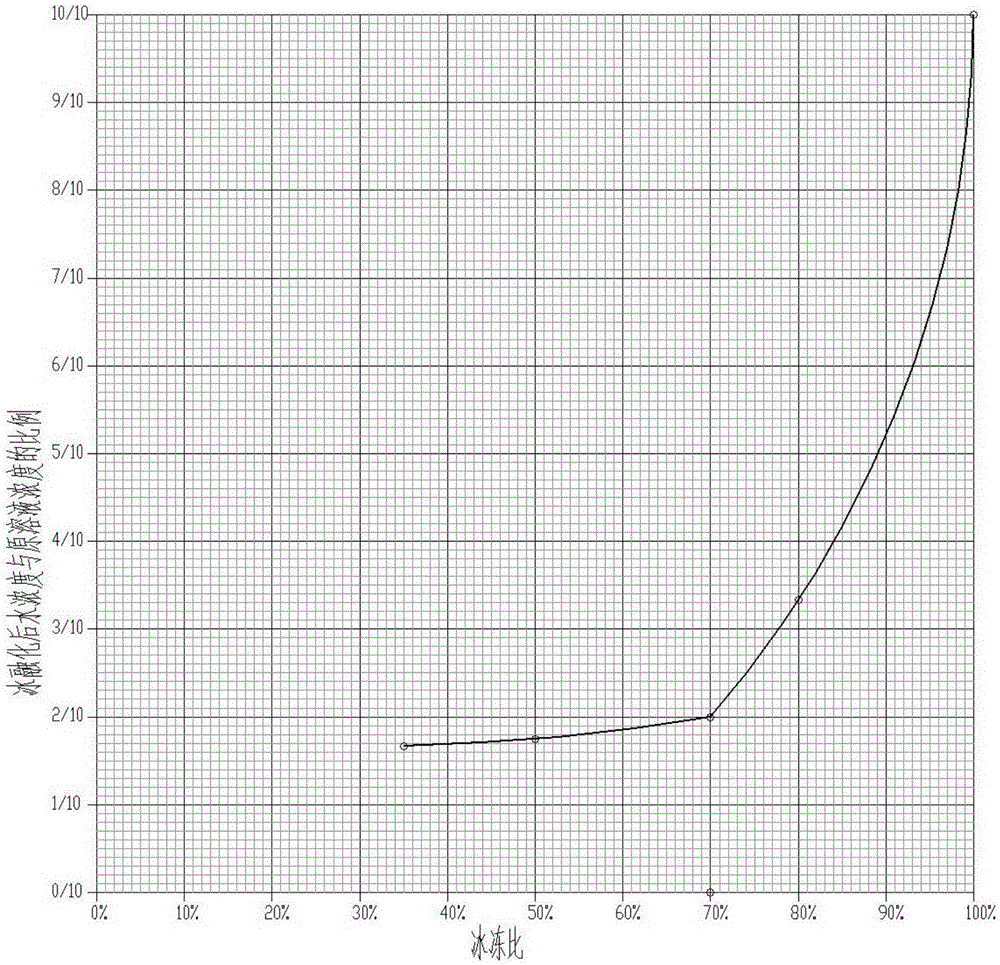

[0042] The following is an embodiment of the relationship between the thickness of ice crystals and the treatment effect of electroplating wastewater.

[0043] Taking the acid copper electroplating process as an example, the concentration of the acid copper electroplating solution is 200g / L, and the electroplating wastewater with a concentration of 20g / L is frozen. The freezing ratio is 70%, forming ice crystals of different thicknesses, and then separating the ice-water mixture. Obtain ice crystals and concentrated wastewater, melt the obtained ice crystals and record the concentration of solute after melting ice crystals of different sizes, the results are shown in Table 1.

[0044] Table 1 The relationship between ice crystals of different sizes and the concentration of solute after the ice crystals melt

[0045]

[0046]

[0047] As the solution freezes, some salt will be entrapped between the ice crystals in the form of salt cells. As time goes by, the salt will for...

Embodiment 3

[0049] The following is an embodiment of the relationship between the concentration of electroplating wastewater and operating profit.

[0050] The fresh water after the melting of the ice crystals is recycled to the water for the washing tank. In consideration of the water quality requirements for the washing water in the washing tank and the cost factor of the wastewater treatment volume, taking the acid copper electroplating process as an example, the concentration of the acid copper electroplating solution is 200g / L, as shown in the table 2 is CuSO in electroplating wastewater 4 Concentration of CuSO in fresh water after melting of ice crystals 4 The relationship between the concentration and the average operating profit rate per cubic meter of wastewater, where the operating profit rate = (average value of waste liquid treatment per cubic meter - average cost of waste liquid treatment per cubic meter) / average waste liquid treatment per cubic meter The cost x 100%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com