A spiral micro-rib water cooling device for laser cladding nozzles

A technology of laser cladding nozzles and cladding nozzles, which is applied in metal material coating process, coating, etc., can solve the problems of laser cladding nozzle temperature rise, great influence on cladding quality, and not obvious cooling effect, etc. , to achieve the effect of improving cladding effect, increasing safety and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

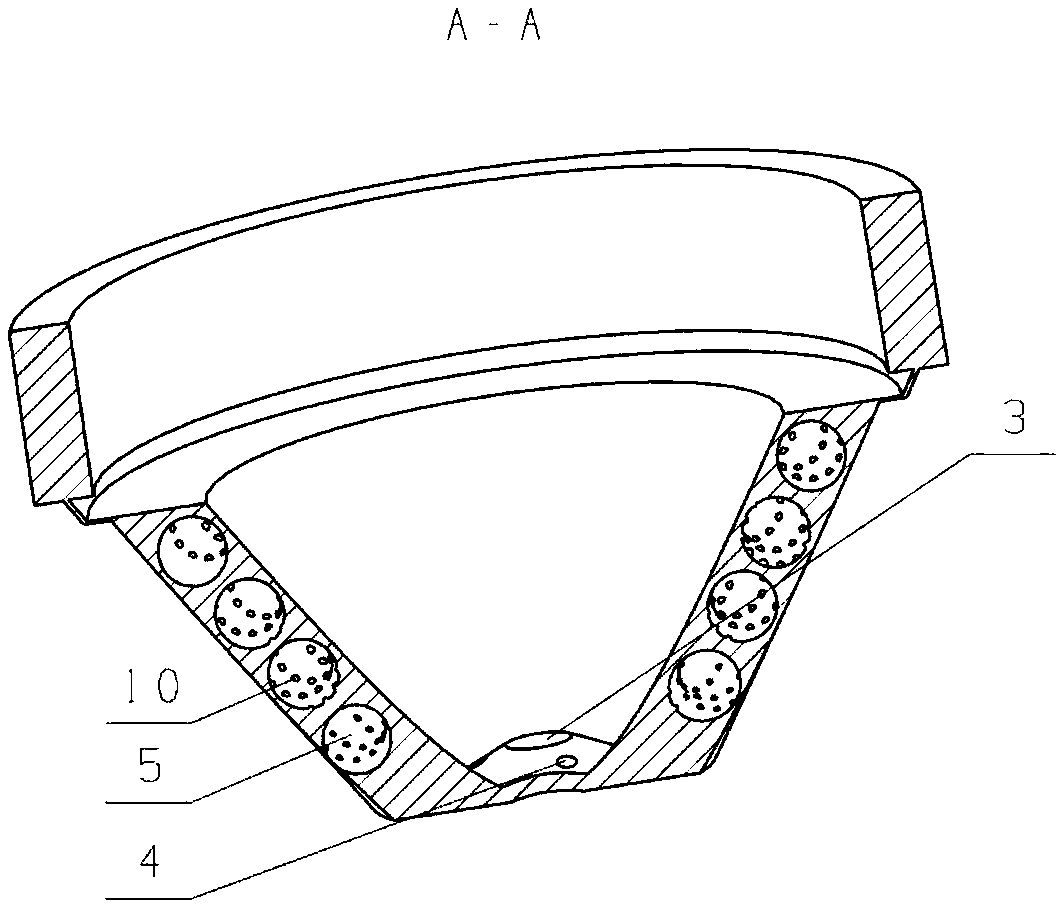

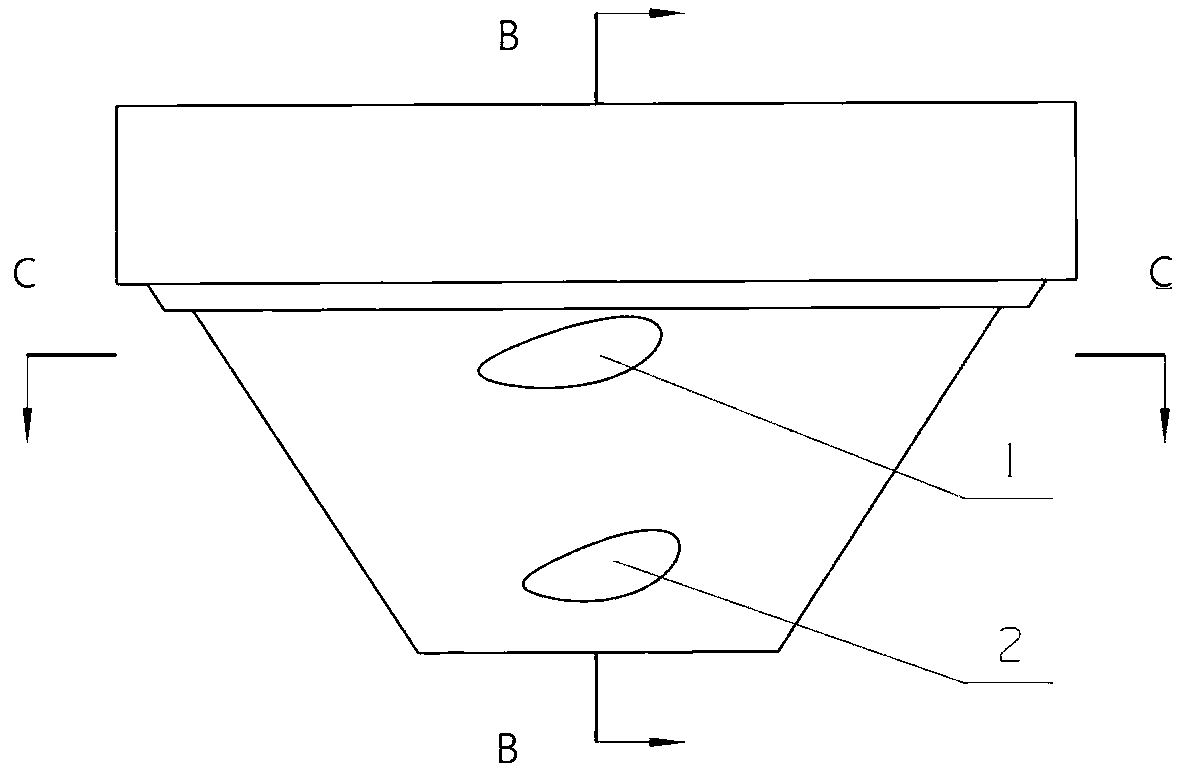

[0027] This embodiment is a spiral micro-ribbed water cooling device for laser cladding nozzles.

[0028] refer to Figure 1 to Figure 8 , the spiral micro-ribbed water cooling device used in the laser cladding nozzle in this embodiment is composed of a water-cooled cone sleeve 8 and a cladding nozzle 9; wherein, the water-cooled cone sleeve 8 also includes an annular channel 5, an arc convex rib 10, and a connecting channel 11 , water outlet 1, water inlet 2, laser hole 3, powder feeding hole 4; the water-cooled cone sleeve 8 is an inverted cone with an integral structure of a ring and a cone. Located at the lower part of the cladding nozzle 9, the water-cooling cone sleeve 8 and the cladding nozzle 9 are connected by thread; the central axis of the water-cooling cone sleeve 8 coincides with the central axis of the cladding nozzle 9, and the structure of the water-cooling cone sleeve 8 is completely clad. Bottom of sprinkler.

[0029] There is an annular channel 5 in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com