A sputtering target self-circulation cooling device

A cooling device and sputtering target technology, applied in the field of magnetron sputtering, can solve the problems of inconvenient target replacement, troublesome target replacement, low target temperature, etc., and achieve controllable and adjustable target temperature, easy replacement The effect of convenient target material and low equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

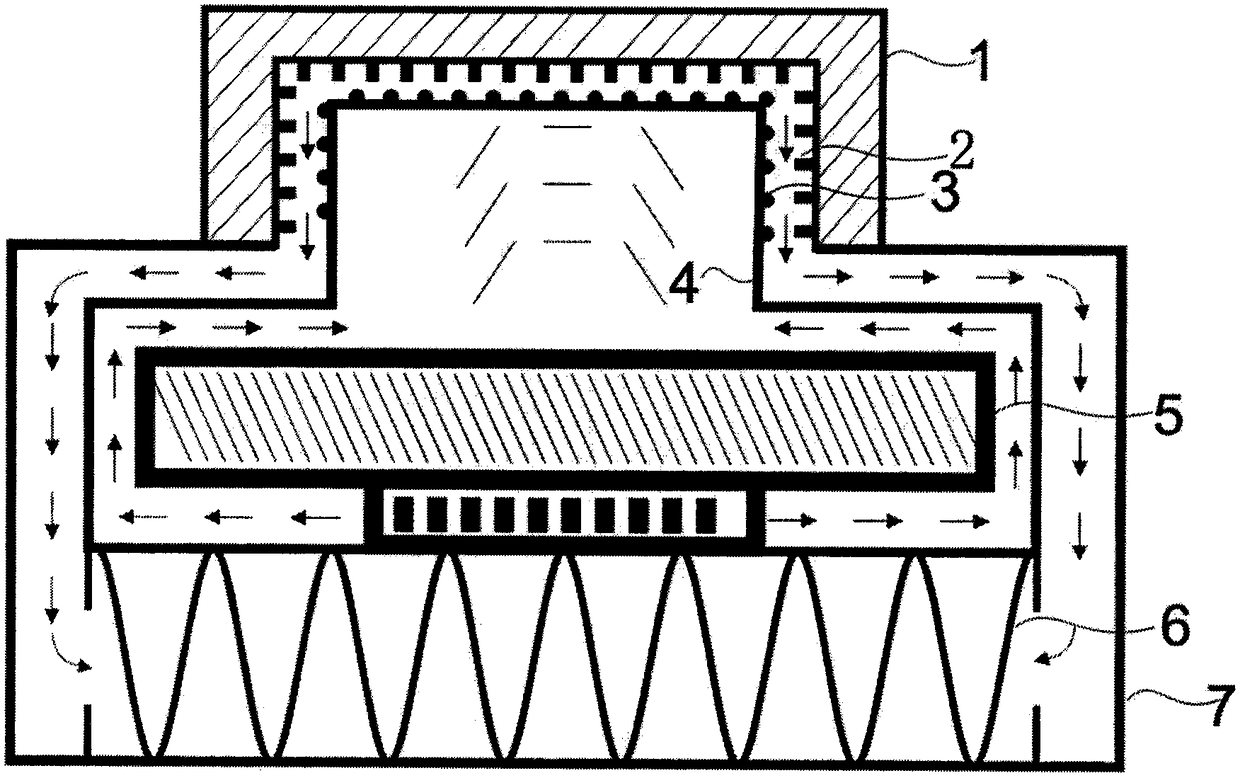

[0014] Such as figure 1 As shown, the target material 1 is cooled by the method of synthetic jet flow, the target material 1 is butted and sealed on the upper end of the metal cathode 7, the synthetic jet generator 5 generates intermittent jet gas, the jet gas is stored by the synthetic jet cavity 4, and is sprayed out along the nozzle 3. The ejected jet gas hits the inner fins 2 of the target 1 to cool down, the heated gas enters the heat dissipation channel 6, and the cooled gas returns to the synthetic jet chamber 4 for recycling.

[0015] Jet gas circulation such as figure 1 As shown, the low temperature environment of the heat dissipation channel 6 can be realized by compressed air refrigeration equipment; the temperature of the target 1 is controlled by the gap distance between the nozzle 3 and the fin 2; at the same time, the frequency of the vibrating film can be controlled by the piezoelectric film; it can also be controlled by the heat dissipation channel 6 temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com