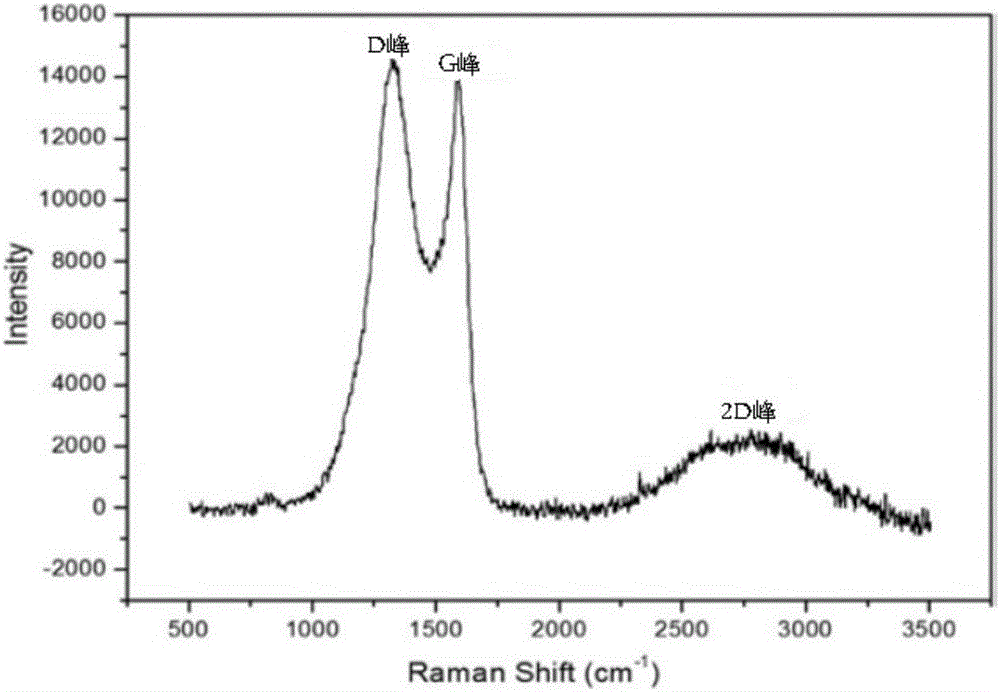

Xylooligosaccharide, dietary fiber and three-dimensional graphene preparation method based on biomass straws

A technology of biomass straw and xylooligosaccharides, applied in the field of bioengineering, can solve the problems of three-dimensional graphene, environmental pollution, waste of mineral resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Cut corn stalks into 3-5cm sections, remove impurities, mix them with solid heteropolyphosphotungstic acid and acidic ionized water in proportion, and carry out a stage of steaming in a reactor (HZ2805BH digester, Zhangjiagang Huahang Paper Machinery Equipment Co., Ltd.). Wherein, the dosage of the solid heteropolyacid is 2 wt% of the dry basis of corn stalks, and the mass ratio of the dry basis of corn stalks to acidic ionized water is 1:6. When carrying out one-stage steaming, feed sulfur dioxide into the reactor, the feeding amount of the sulfur dioxide is 2wt% of the dry basis mass of corn stalks, and the feeding rate is 100m 3 / h, the temperature of the first stage of steaming is about 165°C, the pressure is about 1MPa, and the time is 65min;

[0064] The slurry obtained after one stage of steaming was subjected to five-stage press countercurrent washing with a twin-screw extruder (ZSLXⅡ type twin-screw extruder, Zhucheng Hongyu Light Machine Machinery Co., Ltd.), ...

Embodiment 2

[0076] Cut corn stalks into 3-5cm sections, remove impurities, mix them with solid heteropolyphosphotungstic acid and acidic ionized water in proportion, and carry out a stage of steaming in a reactor (HZ2805BH digester, Zhangjiagang Huahang Paper Machinery Equipment Co., Ltd.). Wherein, the dosage of the solid heteropolyacid is 1 wt% of the dry basis of corn stalks, and the mass ratio of the dry basis of corn stalks to acidic ionized water is 1:3. When carrying out one-stage steaming, feed sulfur dioxide into the reactor, the feeding amount of the sulfur dioxide is 2wt% of the dry basis mass of corn stalks, and the feeding rate is 150m 3 / h, the temperature of the first stage of steaming is about 160°C, the pressure is about 0.8MPa, and the time is 70min;

[0077] The slurry obtained after one stage of steaming was subjected to five-stage press countercurrent washing with a twin-screw extruder (ZSLXⅡ type twin-screw extruder, Zhucheng Hongyu Light Machine Machinery Co., Ltd.)...

Embodiment 3

[0087] Cut the straw into 3-5cm sections, remove impurities, mix with solid heteropolyacid phosphotungstic acid and acid ion water in proportion, and carry out a stage of steaming in a reactor (HZ2805BH digester, Zhangjiagang Huahang Paper Machinery Equipment Co., Ltd.), wherein , the amount of the solid heteropolyacid is 3wt% of the dry weight of rice straw, and the mass ratio of the dry weight of rice straw to acidic ionized water is 1:7. When carrying out one stage of steaming, feed sulfur dioxide into the reactor, the feed rate of said sulfur dioxide is 5wt% of the dry basis mass of rice straw, and the feed rate is 320m 3 / h, the temperature of the first stage of steaming is about 165°C, the pressure is about 0.9MPa, and the time is 73min;

[0088] The slurry obtained after one stage of steaming was subjected to five-stage press countercurrent washing with a twin-screw extruder (ZSLXⅡ type twin-screw extruder, Zhucheng Hongyu Light Machine Machinery Co., Ltd.), and the was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com