Method for metal-enzyme co-catalyzed ethanol production from honeysuckle leaves and simultaneous extraction of chlorogenic acid

A honeysuckle leaf, chlorogenic acid technology, applied in microorganism-based methods, biochemical equipment and methods, organic chemistry and other directions, can solve the problems of increasing production time and equipment occupation, increasing unsafe hazards, and taking a long time, achieving enhanced The effect of hydrolysis and saccharification energy efficiency, environmental protection and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

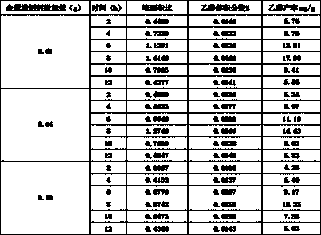

Image

Examples

Embodiment 1

[0025] A metal-enzyme co-catalyzed method for producing ethanol from honeysuckle leaves and simultaneously extracting chlorogenic acid. The specific steps are as follows:

[0026] (1) Preparation of metal activators

[0027] With the chemical reagent MnSO 4 ·H 2 O, FeCl 3 ·6H 2 O, ZnSO 4 ·7H 2 O is the raw material, first according to MnO, ZnO, Fe 2 o 3 The molar ratio of the mixture is 3:2:5 to make a raw material solution and add it to the reactor, then slowly add a precipitant whose molar ratio is 1.5 times that of the raw material solution, and fully stir for 40 minutes in a 50°C water bath. The precipitant is NH 4 HCO 3 . Then add NaOH solution dropwise to adjust the pH value to 7.1, continue to stir for 40 minutes, let it age at room temperature for 12 hours, filter, wash and dry to obtain the precursor. Finally, the precursor was calcined in a muffle furnace at 1140° C. for 3.0 h, cooled naturally to room temperature, and then taken out to obtain the enzyme a...

Embodiment 2

[0037] A metal-enzyme co-catalyzed method for producing ethanol from honeysuckle leaves and simultaneously extracting chlorogenic acid, same as in Example 1, wherein:

[0038] In step (1), MnO, ZnO, Fe 2 o 3 The molar ratio is 4:1:5, the precipitant NH 4 HCO 3 The molar ratio to the raw material solution is 2.0 times, the temperature of the water bath is 80° C., and the stirring time is 60 minutes. The pH value of the solution was adjusted to 10, and the stirring time was continued for 60 min. The calcination temperature in the muffle furnace was 1300° C., and the calcination time was 2.0 h.

[0039] In step (2), the weight ratio of Saccharomyces cerevisiae and Pachysomyces is 1:2, and the mixed culture time is 48 hours.

[0040] In step (3), the mesh number of honeysuckle leaves is selected to be 160 mesh, the oven temperature is 110°C, and the drying time is 30 minutes.

[0041] In step (4), the ratio of biomass raw material mass (g): composite catalyst mass (g): yeast ...

Embodiment 3

[0044] A metal-enzyme co-catalyzed method for producing ethanol from honeysuckle leaves and simultaneously extracting chlorogenic acid, same as in Example 1, wherein:

[0045] In step (1), MnO, ZnO, Fe 2 o 3 The molar ratio is 2:3:5, the precipitant NH 4 HCO 3 The molar ratio to the raw material solution is 1.0 times. After the pH value of the solution was adjusted to 6.5, the stirring time was continued for 20 minutes, the calcination temperature in the muffle furnace was 1000° C., and the calcination time was 6.0 h.

[0046] In step (2), the weight ratio of Saccharomyces cerevisiae and Pachysomyces is 1:3, and the mixed culture time is 36 hours.

[0047] In step (3), the mesh number of honeysuckle leaves is selected as 20 mesh, the oven temperature is 85°C, and the drying time is 90 minutes.

[0048] In step (4), the ratio of biomass raw material mass (g): composite catalyst mass (g): yeast liquid (ml): water volume (ml) is 1: 0.1: 0.5: 15, and the temperature of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com