Printing and dyeing wastewater treating system

A treatment system and technology for printing and dyeing wastewater, applied in the textile industry wastewater treatment, water treatment parameter control, biological water/sewage treatment, etc. , It is difficult to completely realize the complete set of technologies for the wastewater treatment system, so as to achieve the effect of shortening the reaction treatment time, reducing the floor space and construction investment, and shortening the treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

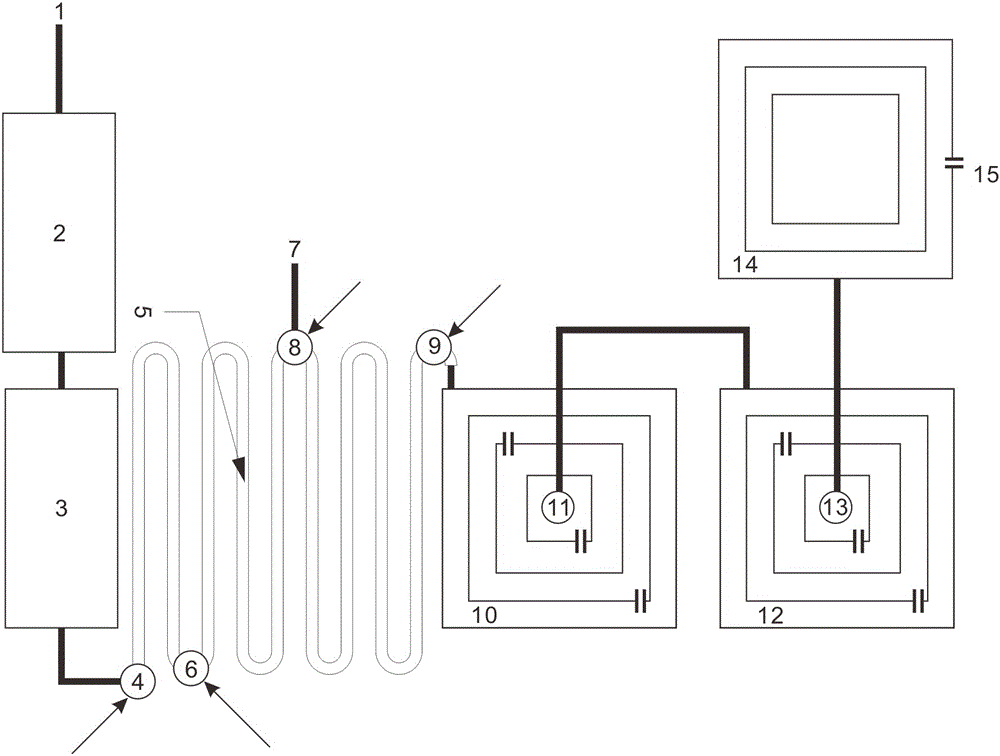

[0024] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] As shown in the figure, the printing and dyeing wastewater treatment system of the present invention includes a grid oil filter tank 2, a sump tank 3, a regulating reaction pipeline group 5, an acid hydrolysis tank 10, a biochemical tank 12, and a sedimentation tank 14.

[0026] The waste water produced by printing and dyeing equipment is divided into medium and heavy waste water 1 and light waste water 7 according to the pollution concentration. The medium and heavy waste water 1 is first treated by the grid oil filter tank 2 to filter out suspended debris and slick oil, and then enter the sump through pipelines 3. The water outlet of the sump 3 is connected to the first feed adjustment pump 4, and the first feed adjustment pump 4 mixes the reaction agent with the waste water in the sump 3 and pumps it into the adjustment reaction pipe group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com