Flotation agent for oily sewage treatment and preparation method thereof

A flotation agent, oily sewage technology, applied in flotation water/sewage treatment, water/sludge/sewage treatment, special compound water treatment, etc. The problems such as rising waste discharge and excessive oil content in production water can achieve the effects of safe synthesis reaction process, easy control of synthesis reaction process, and high oil removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

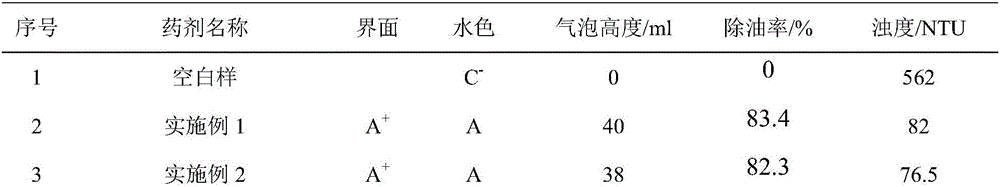

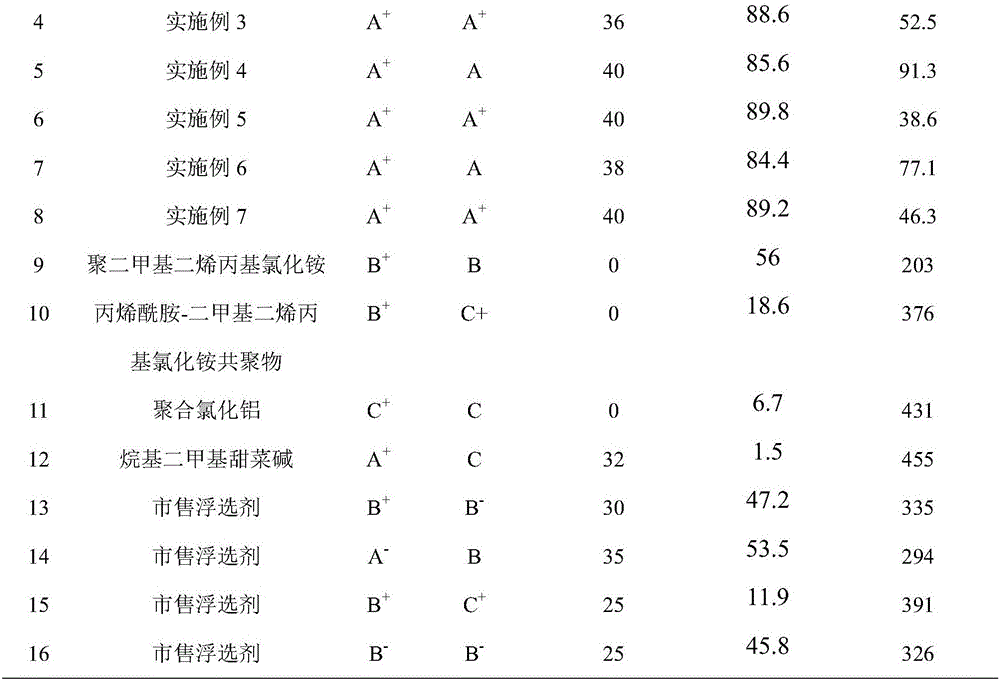

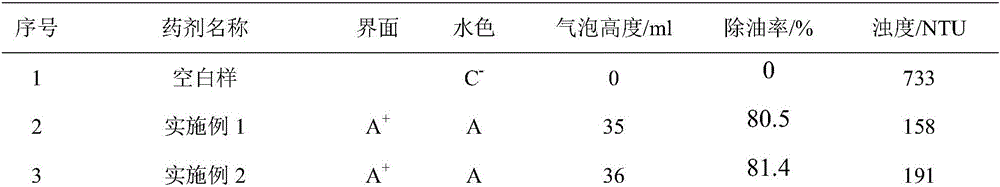

Examples

Embodiment 1

[0027] (1) First mix 20.6g of diethylenetriamine and 23.6g of succinic acid (the molar ratio of diethylenetriamine to succinic acid is 1:1), raise the temperature to 120°C, and stir for 5 hours to obtain amide A1;

[0028] (2) Mix the amide A1 obtained in step (1) with 138g formic acid (analytically pure, with a mass concentration of 94%) (the molar ratio of amide A1 to formic acid is 1:15) evenly, heat up to 80°C, drop The mass concentration that adds 225g is 40% formaldehyde aqueous solution (wherein the mass ratio of formaldehyde and formic acid is 1:1), reaction 1h completes, then add 69g mass concentration and be 50% sodium hydroxide aqueous solution (wherein the sodium hydroxide mass is 50% of the mass of formic acid), stirred for 0.5h hour, adjusted the pH value of the reactant at 10-12, allowed to stand for stratification, and took the upper oil to be polyamide B1;

[0029] (3) Mix the polyamide B1 obtained in step (2), 1,4-dibromobutane with 30% mass of polyamide B1, ...

Embodiment 2

[0032] (1) First mix 29.2g of triethylenetetramine and 29.2g of adipic acid (the molar ratio of triethylenetetramine to adipic acid is 1:1), raise the temperature to 165°C, and stir for 1.5h to obtain amide A2 ;

[0033] (2) Mix the amide A2 obtained in step (1) with 295g formic acid (analytically pure, with a mass concentration of 94%) (the molar ratio of amide A2 to formic acid is 1:32) evenly, heat up to 100°C, and add dropwise The mass concentration of 160g is 40% formaldehyde aqueous solution (wherein the molar ratio of formaldehyde and formic acid substance is 1:3), reaction 4h finishes, then add 295g mass concentration and be 50% sodium hydroxide aqueous solution (wherein the sodium hydroxide mass is the formic acid mass 100%), stirred for 2 hours, adjusted the pH value of the reactant at 10 to 12, allowed to stand for stratification, and took the upper oily substance as polyamide B2;

[0034] (3) the polyamide B2 that step (2) obtains, the 1,4-dibromobutane of 60% of ...

Embodiment 3

[0037] (1) First mix 37.9g of tetraethylenepentamine and 23.6g of succinic acid (the molar ratio of tetraethylenepentamine to succinic acid is 1:1), raise the temperature to 140°C, stir for 3 hours, and obtain amide A3;

[0038] (2) Mix the amide A3 obtained in step (1) with 184g formic acid (analytically pure, with a mass concentration of 94%) (the molar ratio of amide A3 to formic acid is 1:20) evenly, heat up to 90°C, and add dropwise The mass concentration of 150g is 40% formaldehyde aqueous solution (wherein the molar ratio of formaldehyde and formic acid substance is 1:2), reaction 2h finishes, then add 110.4g mass concentration and be 50% sodium hydroxide aqueous solution (wherein the mass concentration of sodium hydroxide is formic acid 60% of the mass), stirred for 1 hour, adjusted the pH value of the reactant at 10 to 12, allowed to stand for stratification, and took the upper oily substance as polyamide B3;

[0039] (3) the polyamide B3 that step (2) obtains, the 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com