Cores for plastic foam molding

A plastic foam and mold core technology, which is applied in the field of plastic foam processing, can solve the problems such as difficulty in removing the mold core, and achieve the effects of reducing difficulty, good condensation effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

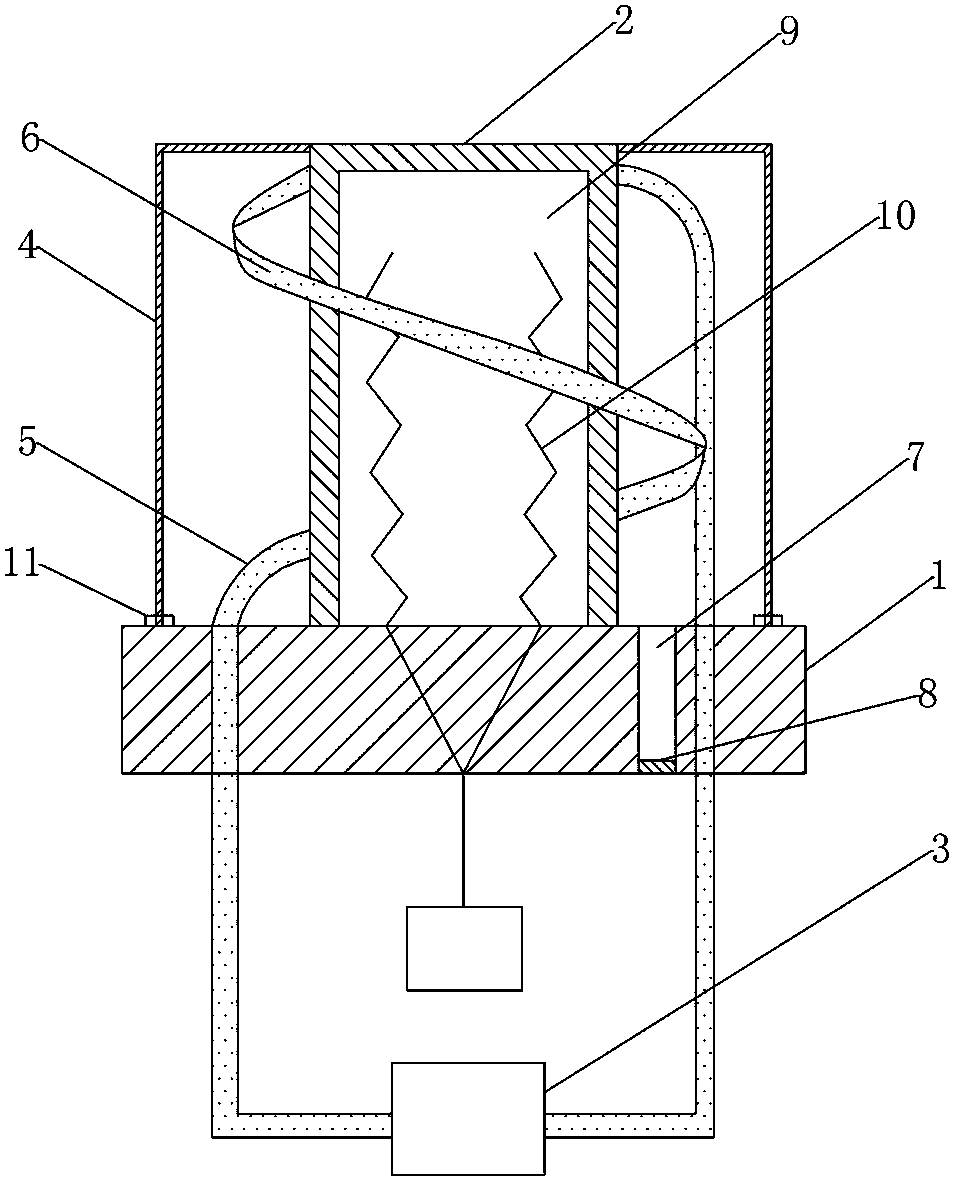

[0018] The reference signs in the accompanying drawings include: base 1, stem 2, heat exchanger 3, tinfoil 4, condensation pipe 5, refrigerant 6, through hole 7, valve 8, cavity 9, heating wire 10, sealing glue11.

[0019] This example is attached figure 1 As shown, the mold core for plastic foam molding includes a base 1 and a stem 2 , the stem 2 is cylindrical, and the bottom end of the stem 2 is fixedly connected to the upper end of the base 1 . A cavity 9 is provided inside the stem 2, and a heating wire 10 for heating up is provided in the cavity 9, and a connecting wire of the heating wire 10 passes through the base 1 to connect with an external power supply. A cylindrical tinfoil 4 is also sleeved outside the stem 2, the top of the tinfoil 4 is fixedly connected to the edge of the top of the stem 2, the bottom of the tinfoil 4 is fixedly connected to the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com