Cutter wheel

A cutting wheel and cutting edge technology, applied in stone processing equipment, other manufacturing equipment/tools, shearing devices, etc., can solve the problems of inability to precisely machine the size of the cutting edge, unable to maintain the rotating surface horizontally, etc., to prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

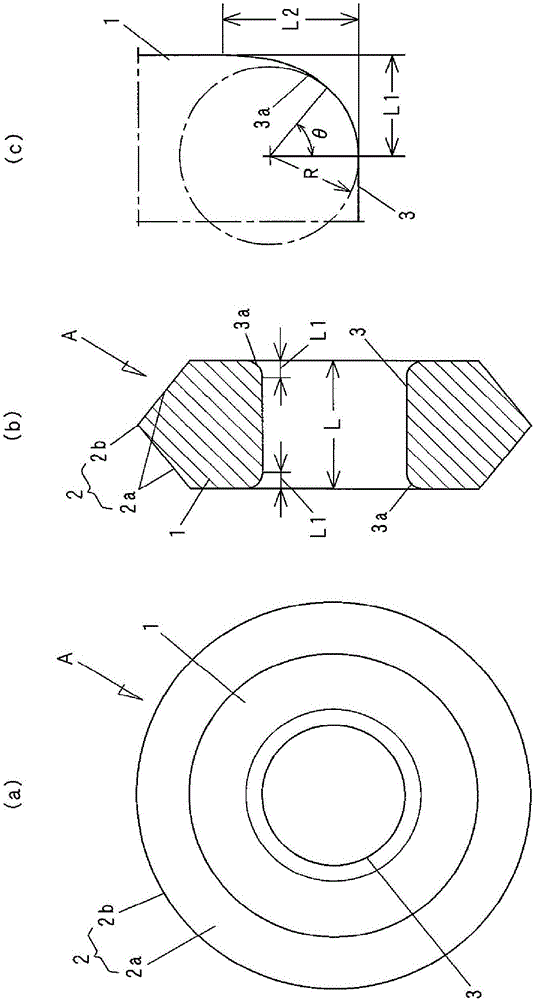

[0024] Below, based on figure 1 , figure 2 The cutter wheel of the present invention will be described in detail.

[0025] figure 1 It is a figure showing the cutter wheel A of the present invention, figure 1 (a) is the front view, figure 1 (b) is a side sectional view, figure 1 (c) is an enlarged view of the arc surface 3a portion of the bearing hole 3 . This cutter wheel A is made only of single crystal diamond, and a blade portion 2 is provided on the outer peripheral surface of a disk-shaped main body 1 having a bearing hole 3 penetrating the center. The blade portion 2 is composed of left and right slopes 2a, 2a and a ridge line 2b formed at the intersection of these slopes 2a, 2a. In this embodiment, the cutter wheel A is formed to have a diameter of 2 mm and a thickness of 650 μm.

[0026] The bearing hole 3 of the disc-shaped main body 1 is formed by a through hole with a constant inner diameter, and the opening edges at both ends thereof are formed by arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com