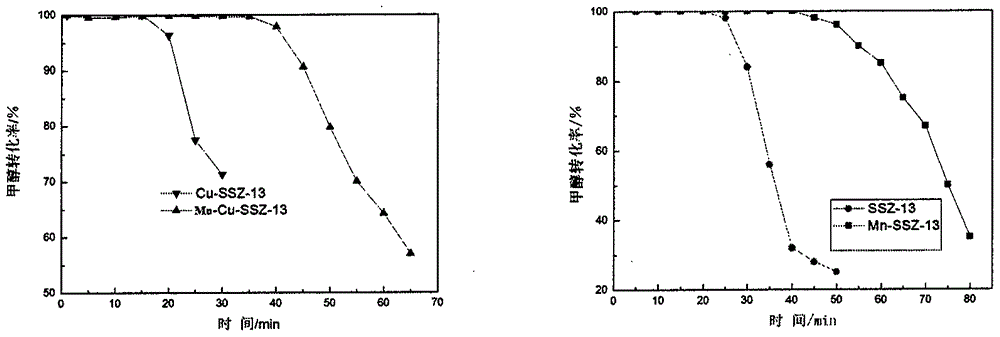

Preparation of a metal manganese modified silicon-aluminum molecular sieve material Mn-SSZ-13, and applications of the material in alkene preparation from methanol and denitration

A silicon-aluminum molecular sieve and metal manganese technology, applied in the field of methanol to olefins and denitrification, can solve the problem of serious hydrogen transfer side reactions and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of gel: Dissolve 1.3856g of solid sodium metaaluminate in 17.4872ml of deionized water, add 4.0673g of copper nitrate and 3.6078g of tetraethylenepentamine solution in turn to form a Cu-TEPA complex, and then add 2.7755g of solid hydrogen Sodium oxide and fully stirred, then added dropwise 16.2360g silica sol (SiO 2 The mass fraction is 30.72%), stirred at room temperature for 4 hours to obtain a uniform gel.

[0027] Crystallization: Put the initial gel into a PTFE high-pressure reactor and crystallize at 140°C for 4 days. After the crystallization is completed, the product is washed with deionized water and dried at 100°C for 12 hours to obtain Cu-Na-SSZ -13 molecular sieves.

[0028] Ammonium exchange: Take 3g of the above-mentioned roasted sample, put it into a 100ml beaker, add a solution made of 10.68g of ammonium chloride and 200g of deionized water, heat up to 80°C and keep stirring for 4h, filter with suction, and then add 200g of deionized water f...

Embodiment 2

[0033] Preparation of lye: add 0.83g of sodium hydroxide to 18g of water, stir until the sodium hydroxide dissolves, add 3.43g of N,N,N-trimethyladamantane ammonium hydroxide (template agent), and stir until a homogeneous solution.

[0034] Preparation of gel: Add 13.05g of silica sol to the reaction kettle, stir in a water bath at room temperature, then add lye, stir evenly, add 3.25g of aluminum sulfate, stir evenly, add 0.16g of molecular sieve of chabazite (CHA) crystal phase as crystal species, and stirred at room temperature for 4 hours to obtain a homogeneous gel.

[0035] Crystallization: Put the initial gel into a PTFE autoclave and crystallize at 165°C for 2-4 days. After the crystallization is complete, wash the product with deionized water until the filtrate is neutral, and dry at 100°C for 12 hours .

[0036] Roasting: The dried samples were heated up to 600°C in an air atmosphere for 4 hours, and then baked for 4 hours.

Embodiment 3

[0040] Preparation of gel: Dissolve 1.3856g of solid sodium metaaluminate in 17.4872ml of deionized water, add 4.0673g of copper nitrate and 3.6078g of tetraethylenepentamine solution in turn to form a Cu-TEPA complex, and then add 2.7755g of solid hydrogen Sodium oxide and fully stirred, then added dropwise 16.2360g silica sol (SiO 2 The mass fraction is 30.72%), stirred at room temperature for 4 hours to obtain a uniform gel.

[0041] Crystallization: Put the initial gel into a PTFE high-pressure reactor and crystallize at 140°C for 4 days. After the crystallization is completed, the product is washed with deionized water and dried at 100°C for 12 hours to obtain Cu-Na-SSZ -13 molecular sieves.

[0042] Ammonium exchange: Take 3g of the above-mentioned roasted sample, put it into a 100ml beaker, add a solution made of 10.68g of ammonium chloride and 200g of deionized water, heat up to 80°C and keep stirring for 4h, filter with suction, and then add 200g of deionized water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com