Vertically aligned layered double hydroxides (LDHs) film and application thereof in structured catalysis

A structured catalyst, vertical orientation technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., to avoid loss, high catalytic activity, rich variety and application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

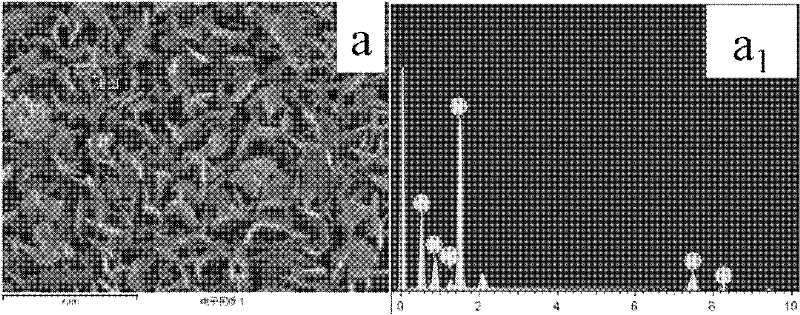

Embodiment 1

[0036] Step A: Select 450cm 2 (30cm×15cm×0.2cm) aluminum sheet, then roll the aluminum sheet into a 600ml sealed cup, then ultrasonically clean it with acetone for 15 minutes, then ultrasonically clean it with ethanol for 15 minutes, and finally clean it with deionized water After 10 minutes, take out the cleaned aluminum sheet for later use;

[0037] Step B: 8.20g (0.032mol) of solid Mg(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution I);

[0038] Step C: 8.20g (0.032mol) of Mg(NO 3 ) 2 ·6H 2 O solid, 1.86g of Ni(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution II);

[0039] Step D: Immerse the aluminum sheet cleaned in step A into solution I and seal it, then place the sealed cup in a 70°C water bath...

Embodiment 2

[0041] Step A: Select 450cm 2 (30cm×15cm×0.2cm) aluminum sheet, then roll the aluminum sheet into a 600ml sealed cup, then ultrasonically clean it with acetone for 15 minutes, then ultrasonically clean it with ethanol for 15 minutes, and finally clean it with deionized water After 10 minutes, take out the cleaned aluminum sheet for later use;

[0042] Step B: 8.20g (0.032mol) of solid Mg(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution I);

[0043] Step C: 8.20g (0.032mol) of Mg(NO 3 ) 2 ·6H 2 O solid, 0.47g of Ni(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution II);

[0044] Step D: Immerse the aluminum sheet cleaned in step A into solution I and seal it, then place the sealed cup in a 70°C water bath...

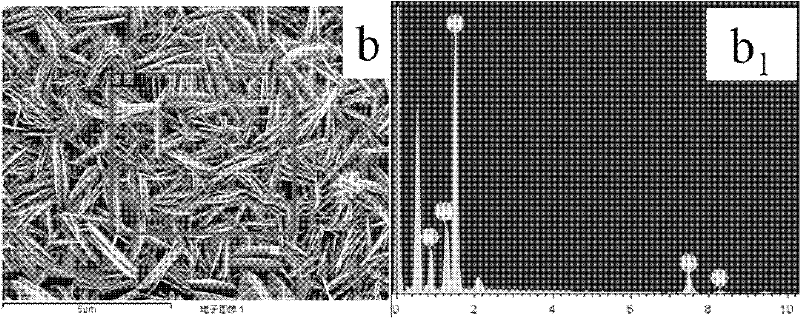

Embodiment 3

[0046] Step A: Select 450cm 2 (30cm×15cm×0.2cm) aluminum sheet, then roll the aluminum sheet into a 600ml sealed cup, then ultrasonically clean it with acetone for 15 minutes, then ultrasonically clean it with ethanol for 15 minutes, and finally clean it with deionized water After 10 minutes, take out the cleaned aluminum sheet for later use;

[0047] Step B: 9.50g (0.032mol) of solid Zn(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution I);

[0048] Step C: 9.50g (0.032mol) of Zn(NO 3 ) 2 ·6H 2 O solid, 1.89g of Cu(NO 3 ) 2 ·6H 2 O and 11.64g (0.194mol) of urea were dissolved in a 650mL sealed cup, and 600ml of deionized water was added and stirred to fully dissolve and disperse evenly (solution II);

[0049] Step D: Immerse the aluminum sheet cleaned in step A into solution I and seal it, then place the sealed cup in a 70°C water bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com