Modified bio-char as well as preparation method and application thereof

A biochar modification technology, applied in chemical instruments and methods, other chemical processes, multi-stage water treatment, etc., can solve the problems of difficult filtration, large consumption of flocculant, poor decolorization effect, etc., and increase the adsorption capacity , reduce processing costs, increase the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

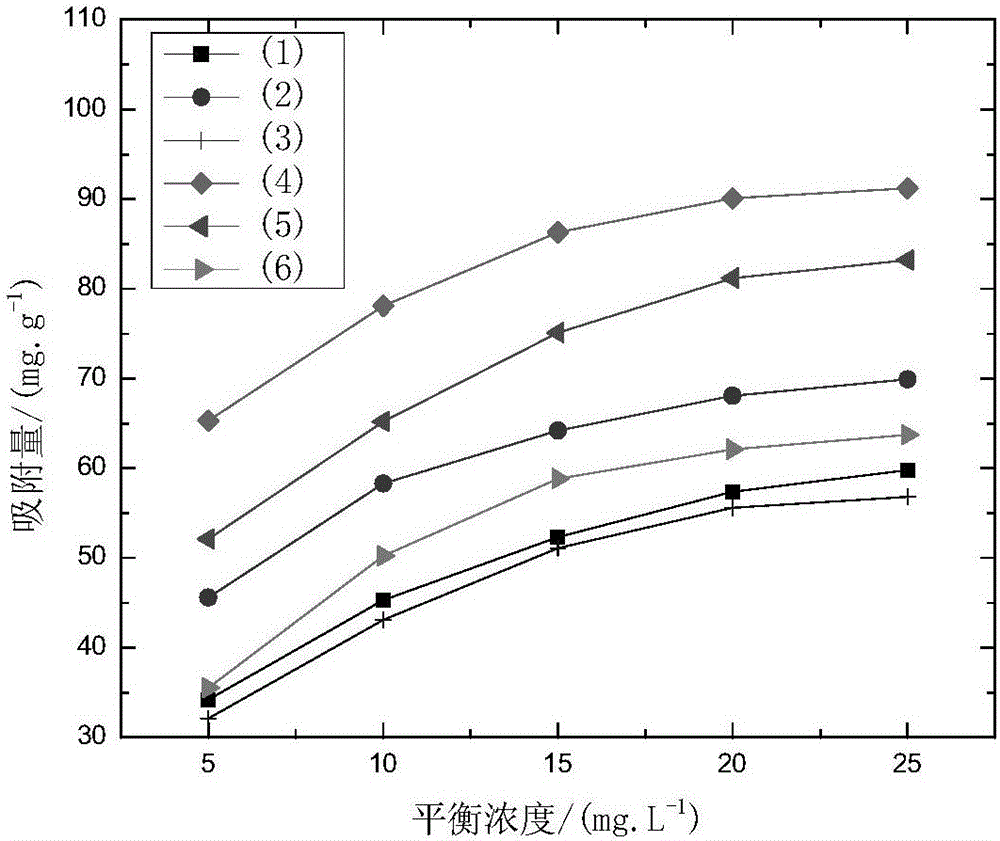

[0033] Determination of Adsorption Capacity of Acid-Modified Biochar

[0034] The preparation method of the biochar of acid modification comprises the following steps:

[0035] (1) Preparation of biochar

[0036] The rice husks, coconut shells and wood chips collected from the countryside are crushed, and mixed according to the mass ratio of rice husks, coconut shells and wood chips of 100 to 110: 3 to 5: 8 to 15. In this embodiment, six mass Ratio, respectively 100:3:8, 100:5:8, 110:3:8, 110:5:8, 110:3:15 and 110:5:15, washed, air-dried, in vacuum / atmosphere tube Carbonization was carried out in an electric furnace at 400 °C for 4 h under the protection of nitrogen, and six kinds of biochars were obtained after cooling.

[0037] (2) Preparation of acid-modified biochar

[0038] Weigh 100 g of the above 6 kinds of biochars respectively and place them in a reaction vessel, add 1 L of hydrochloric acid solution with a concentration of 1 mol / L, and ultrasonically soak for 1 h....

Embodiment 2

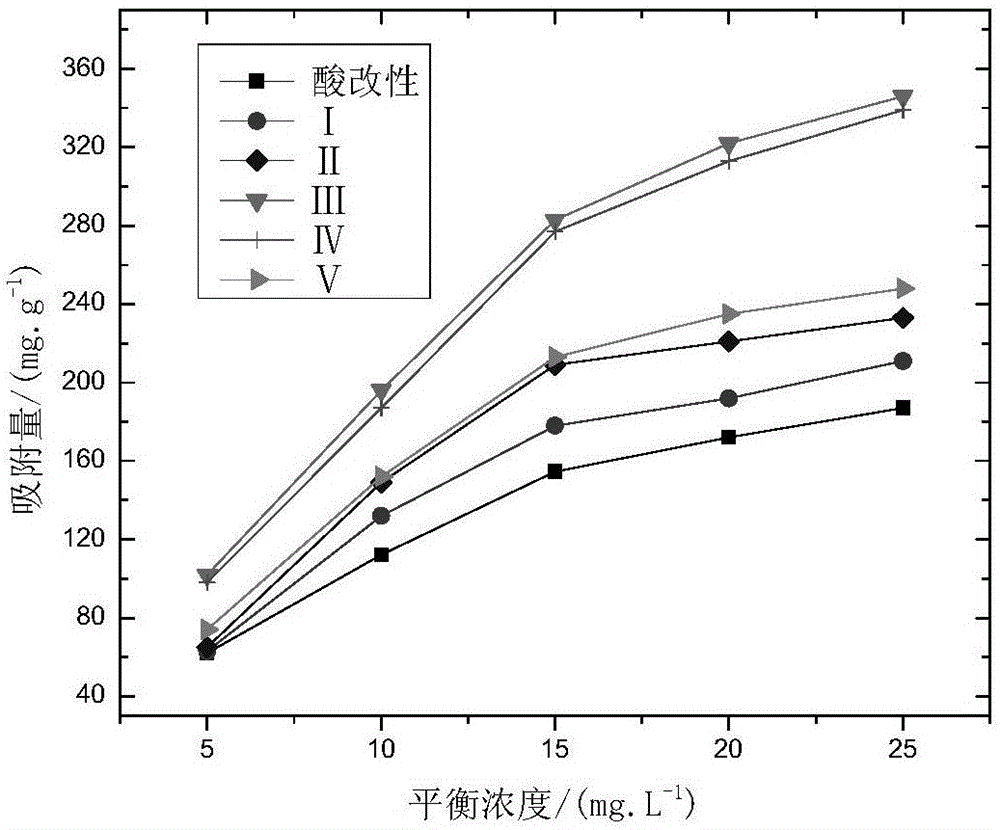

[0045] A modified biochar of the present invention is obtained by impregnating acid-modified biochar through a micelle system, and the micelle system is composed of anionic biosurfactant, cationic chemical surfactant and humic acid solution.

[0046] In this embodiment, the anionic biosurfactant is rhamnolipid; the cationic chemical surfactant is cetyltrimethylammonium bromide, a quaternary ammonium salt surfactant.

[0047] In this example, the biochar is obtained by carbonization after mixing rice husk, coconut shell and sawdust.

[0048] A preparation method of the modified biochar of the present embodiment, comprising the following steps:

[0049] (1) Preparation of biochar

[0050] The rice husks, coconut shells, and sawdust collected from the countryside were crushed, mixed according to the mass ratio of rice husks, coconut shells, and wood chips at 110:5:8, washed, air-dried, and heated at 400°C in a vacuum / atmosphere tube-type electric furnace. Carbonize under the pr...

Embodiment 3

[0058] A modified biochar of the present invention is obtained by impregnating acid-modified biochar through a micelle system, and the micelle system is composed of anionic biosurfactant, cationic chemical surfactant and humic acid solution.

[0059] In this embodiment, the anionic biosurfactant is rhamnolipid; the cationic chemical surfactant is cetyltrimethylammonium bromide, a quaternary ammonium salt surfactant.

[0060] In this example, the biochar is obtained by carbonization after mixing rice husk, coconut shell and sawdust.

[0061] A preparation method of the modified biochar of the present embodiment is basically the same as the preparation method of embodiment 2, the difference is that the volume ratio of rhamnolipid solution, CTAB solution and humic acid solution in step (3) is 1 :6:20. The prepared modified biochar is numbered II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com