Copper hydroxide nanowire/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

A technology of polyvinylidene fluoride and copper hydroxide, which is applied in chemical instruments and methods, ultrafiltration, membranes, etc., can solve the problems of limiting the promotion of polyvinylidene fluoride, blocking pores, and reducing membrane water flux, and achieves anti-pollution Effects of performance improvement, hydrophilicity enhancement, and water flux enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

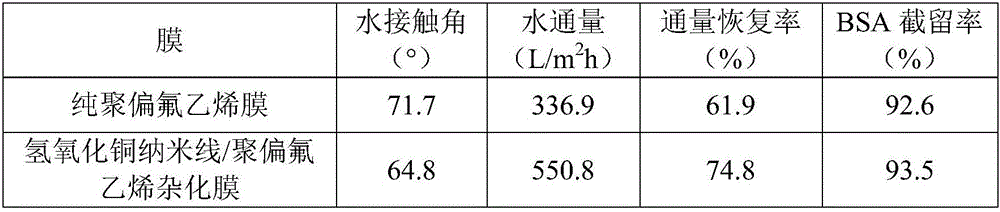

Embodiment 1

[0030] 1) Dissolve 0.998g of analytically pure copper sulfate pentahydrate in 20mL of distilled water under magnetic stirring; stir for 15 minutes until the copper sulfate pentahydrate is completely dissolved, then quickly add 30mL of analytical solution with a concentration of 0.15mol / L under constant stirring. Pure ammonia solution, after 15min a large amount of [Cu(NH 3 ) 4 2+ ]; then 6mL concentration of 1.2mol / L of sodium hydroxide solution was added dropwise in the above solution, along with the addition of sodium hydroxide, the pH value of the solution increased, resulting in [Cu(NH 3 ) 4 2+ ] The stability of the complex is reduced, so the blue copper hydroxide is quickly precipitated. After the drop is completed, it is fully reacted for 1 hour, washed, filtered, and dried at 20-40°C to obtain copper hydroxide nanowires; copper hydroxide nanowires The length of the wire is 600-1000 nm, and the aspect ratio is 120-200.

[0031] 2) Prepare 35g of casting solution: m...

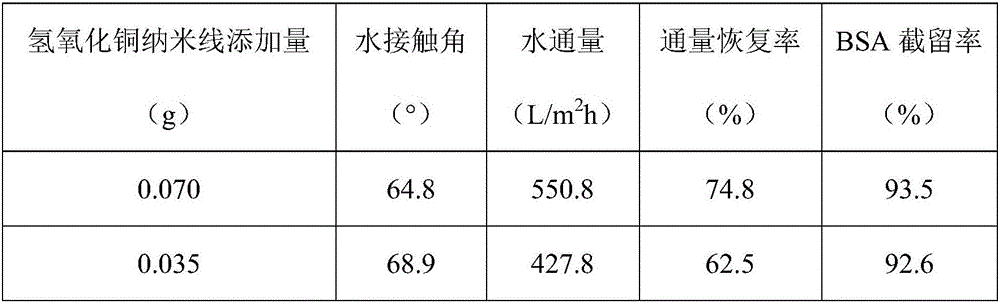

Embodiment 2

[0040] 1) The preparation of copper hydroxide nanowires is exactly the same as in Example 1.

[0041] 2) The difference from Example 1 is that the amount of copper hydroxide nanowires added in the casting solution is different. The specific operation is as follows: Prepare 35g of casting solution: mix 0.035g of copper hydroxide nanowires and 26.915g of N,N-dimethylacetamide, and ultrasonicate at room temperature for 20min to obtain a uniform dispersion of copper hydroxide nanowires;

[0042] Add 7g of polyvinylidene fluoride (dried in vacuum at 110°C for 12h before use), and 1.05g of polyvinylpyrrolidone (molecular weight: 40,000g / mol) into the above copper hydroxide nanowire dispersion in sequence, stir at 60°C for 24h, and then Stand at constant temperature at 60°C for 24 hours to remove air bubbles to obtain a uniform casting solution, and then evenly scrape the casting solution onto a clean and scratch-free glass plate to form a cast layer with a thickness of 130 -250μm; ...

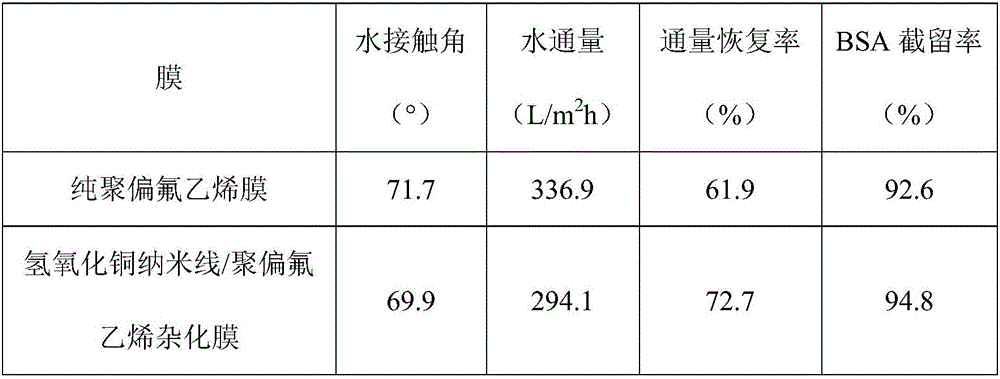

Embodiment 3

[0048] 1) The preparation of copper hydroxide nanowires is exactly the same as in Example 1.

[0049] 2) The difference from Example 1 is that the amount of copper hydroxide nanowires added in the casting solution is different. The specific operation is as follows: prepare 35g of casting solution: mix 0.105g of copper hydroxide nanowires and 26.845g of N,N-dimethylacetamide, and ultrasonicate at room temperature for 20min to obtain a uniform dispersion of copper hydroxide nanowires;

[0050] Add 7g of polyvinylidene fluoride (dried in vacuum at 110°C for 12h before use), 1.05g of polyvinylpyrrolidone (molecular weight: 40000g / mol) into the above-mentioned copper hydroxide nanowire dispersion, stir at 60°C for 24h, and then Stand at constant temperature for 24 hours at ℃ to remove air bubbles to obtain a uniform casting solution, and then evenly scrape the casting solution onto a clean and scratch-free glass plate to form a casting layer. The thickness of the casting layer is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com