Production method of green tea instant tea capable of resisting inflammation and relieving cough

A production method and instant tea technology, which is applied in tea, tea extraction, food science, etc., can solve the problems of complex preparation process, too many and too complicated Chinese medicine ingredients, etc., and achieve the effect of high extraction rate, high activity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0045] The following production process is used to prepare green tea:

[0046] (1) The raw material is a single bud. After picking the fresh leaves, the fresh leaves are collected in batches and aired in a clean bamboo plaque in a cool and ventilated place. The water content is reduced to 70% for 7 hours.

[0047] (2) Microwave curing: Put the dried leaves into a microwave curing machine for microwave curing. The M700 microwave oven of Guangdong Midea Microwave Manufacturing Co., Ltd. is used. The amount of leaves is 40g, the microwave power is 650W, and the curing time is 120s. The curing temperature is 150°C. At this time, the water content of the killing leaves was 50%.

[0048] (3) Kneading: Kneading the above-mentioned microwave curing leaves to obtain a single bud. The 255 type rolling and twisting machine is used for warm rolling, the amount of leaves is 60g, and the time is 20min.

[0049] (4) Vacuum drying: Using the DZF-6501 vacuum drying oven produced by Shanghai Jinghong...

Embodiment 1

[0052] The following production process is used to prepare instant tea with anti-inflammatory and anti-cough green tea:

[0053] (1) Microwave the fresh Houttuynia cordata in a M700 microwave oven to kill enzymes, with 50g leaf throw, 550W microwave power, and 45s killing time;

[0054] (2) Crush the killed Houttuynia cordata to 100 mesh, and crush the green tea of Preparation Example 1 and commercial licorice to 25 mesh and 40 mesh respectively;

[0055] (3) Mix the crushed houttuynia cordata, green tea and licorice according to the weight ratio of 20:55:25;

[0056] (4) Use a mixture of water and ethanol with a volume ratio of 100:20 to extract the mixture obtained in step (3), and add protease, cellulase and pectinase in a mass ratio of 1:1:1 during extraction. Enzymatic hydrolysis of the composite enzyme, the mass volume fraction of the composite enzyme is 0.5%, the volume-mass ratio of the extract to the mixture is 500mL:100g, the extraction temperature is 50°C, the extraction ...

Embodiment 2-8

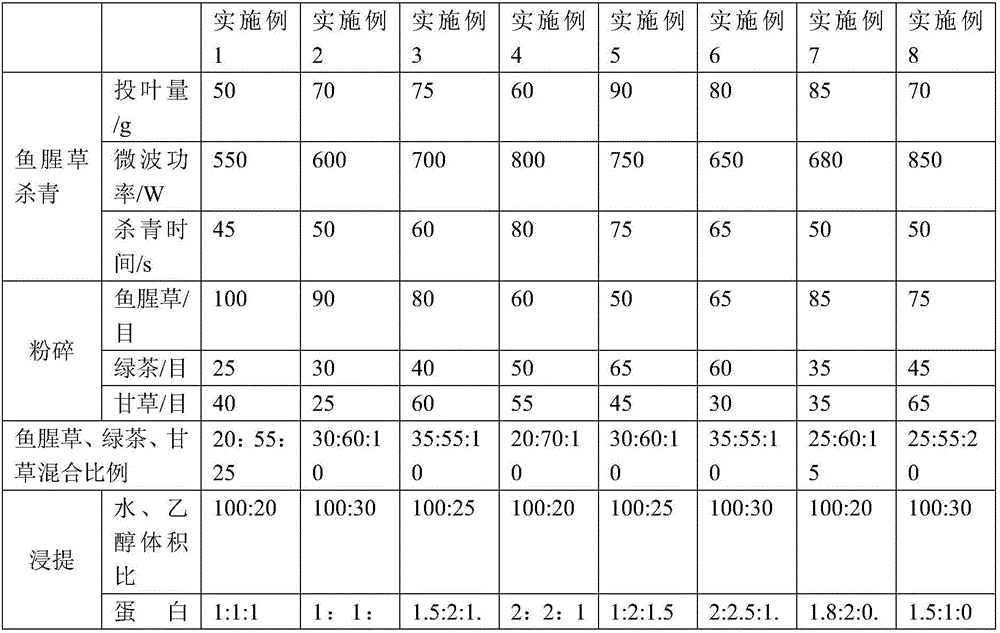

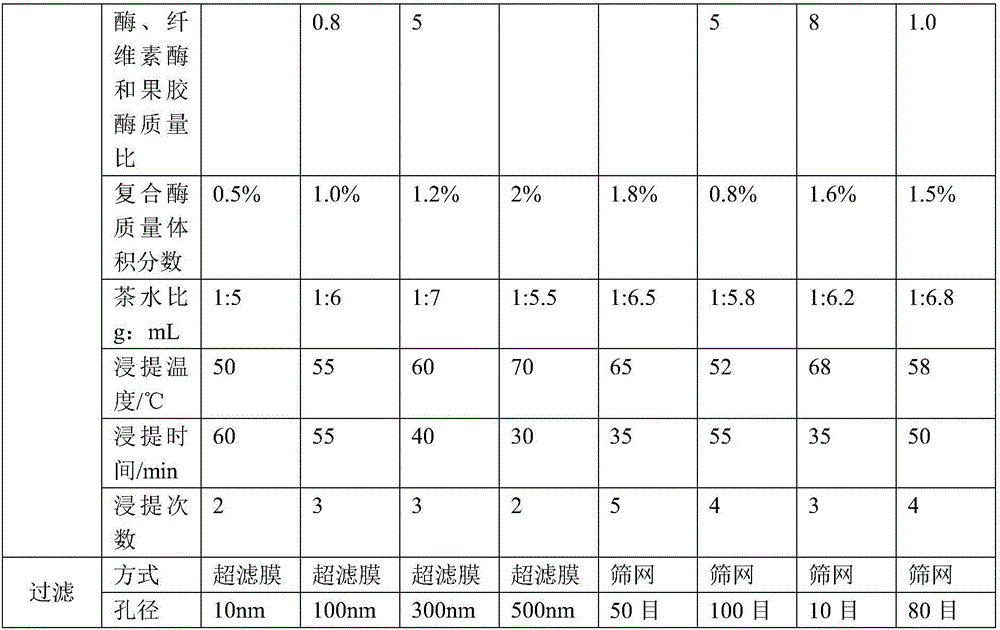

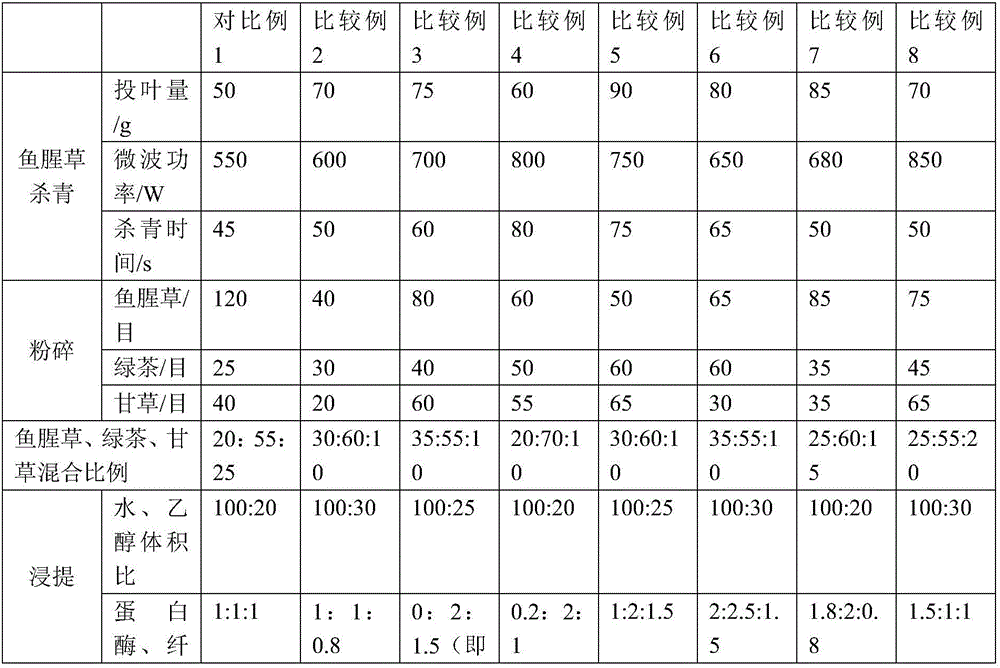

[0060] The instant tea process is basically the same as in Example 1, and the specific process parameters are different in the process conditions in Table 1. In addition, Examples 7 and 8 used ordinary commercial green tea as raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com