Inductive-reactance type oil detection system and manufacturing method thereof

A detection system and manufacturing method technology, applied in the direction of measuring device, material impedance, material resistance, etc., can solve the problems that metal particles cannot be distinguished, water droplets and air bubbles cannot be detected, and various particles cannot be comprehensively detected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

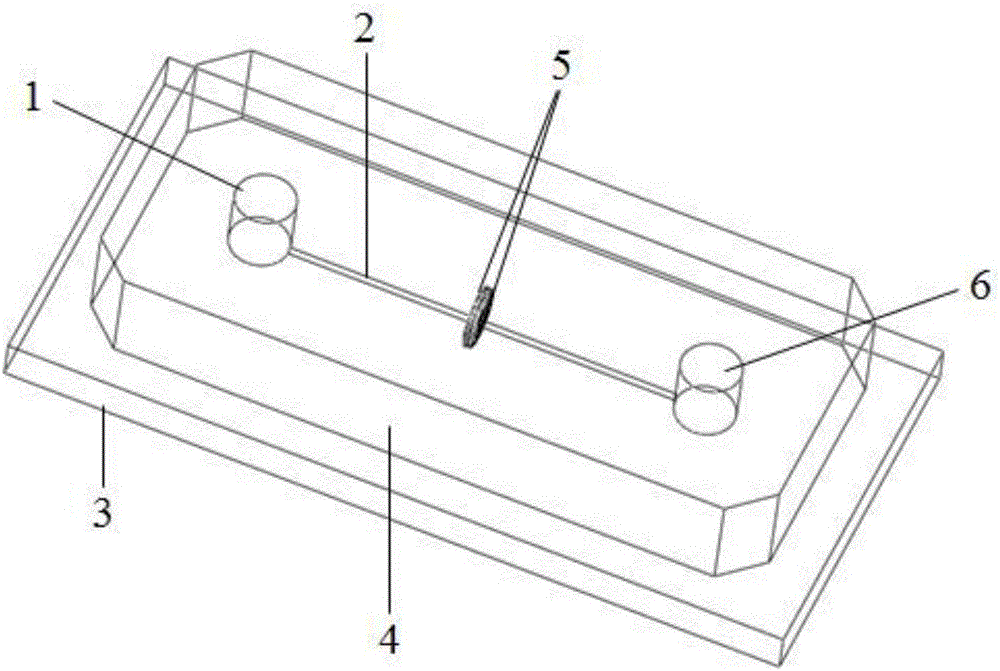

[0050] Combine figure 1 , figure 2 with image 3 , See Image 6 , An inductive reactance oil detection system, including a detection device, a measurement mode switching unit 11, and an excitation-detection unit 12.

[0051] The detection device includes a microfluidic chip and a sensing unit 5. The microfluidic chip includes a microchannel inlet 1, a microchannel 2, a substrate 3, a model material 4, and a microchannel outlet 6.

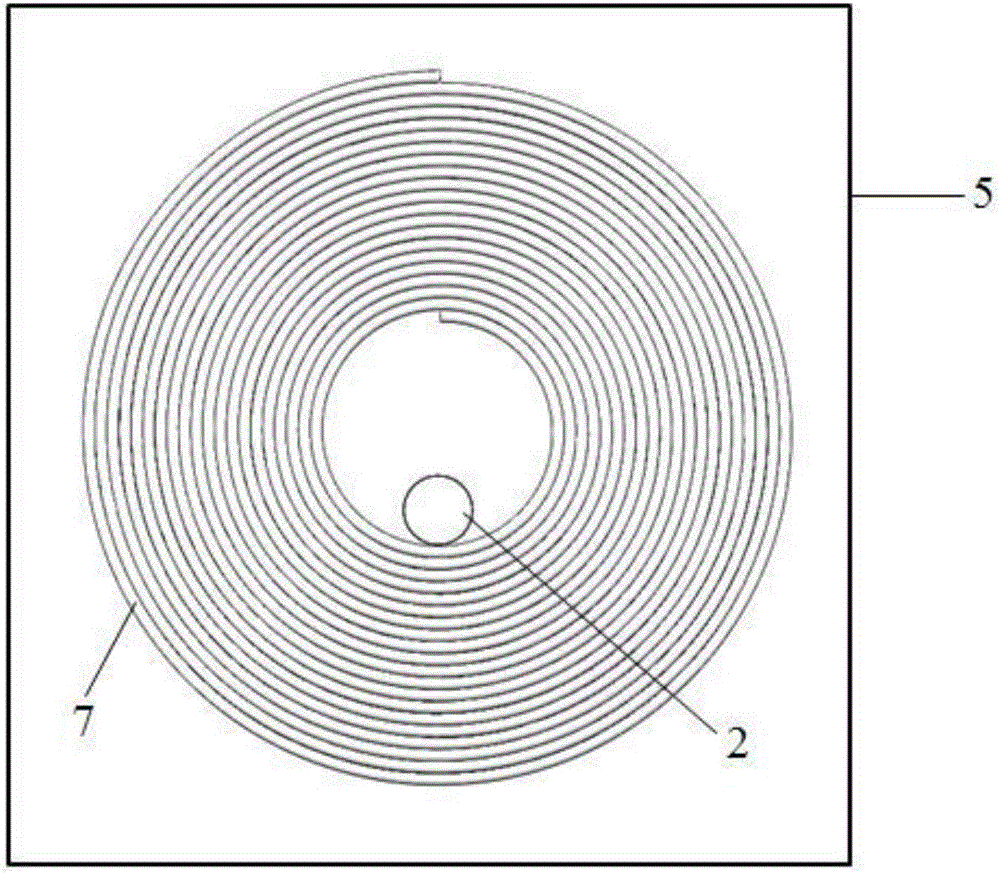

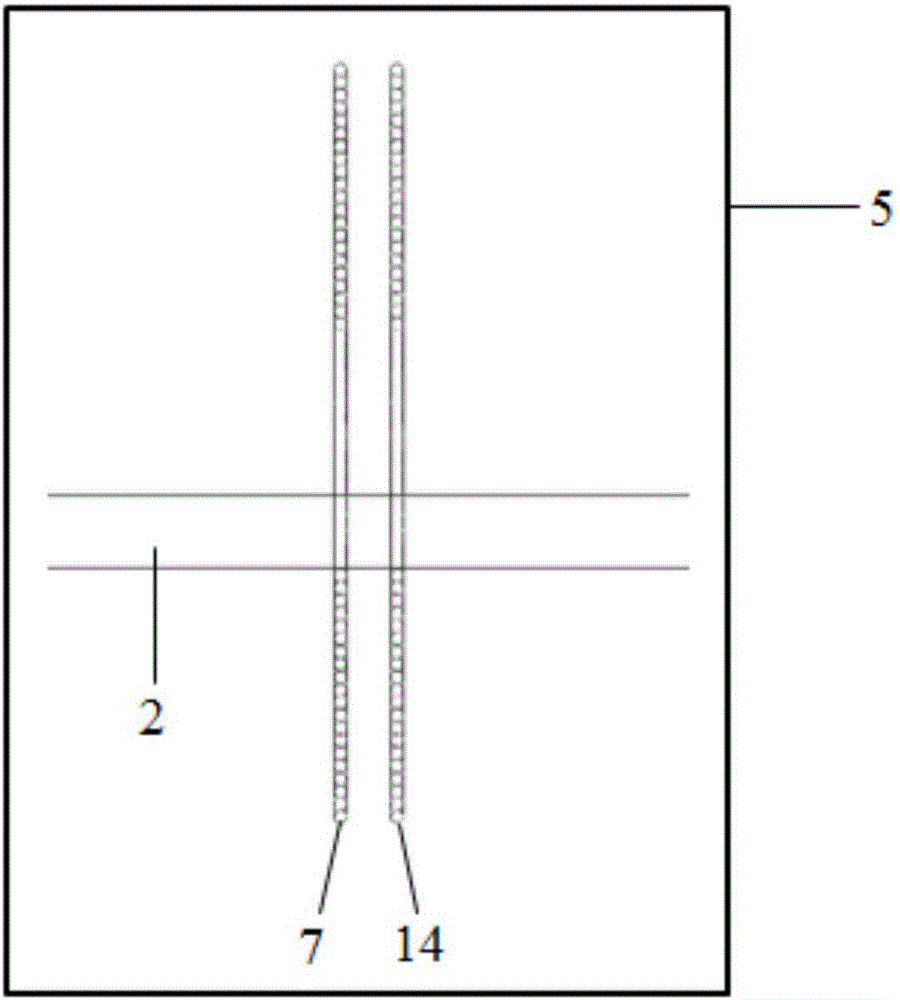

[0052] The sensing unit 5 is composed of two identical first single-layer coils 7 and second single-layer coils 14. The two single-layer coils 7 and 14 are arranged opposite each other, and the microchannel 2 is separated from the two single-layer coils. 7 and 14 pass through the inner holes; the first single-layer coil 7 has a first lead end 15 and a second lead end 16, and the second single-layer coil 14 has a third lead end 17 and a fourth lead end 18.

[0053] The two single-layer coils 7, 14 are wound by enameled wire, the inner diameter of the coil...

Embodiment 2

[0063] See figure 1 with Image 6 The manufacturing method of the inductive reactance oil detection system of the present invention is divided into three steps in total, specifically:

[0064] The first step is to make a detection device. First, fix the micro-channel mold and the two single-layer coils 7, 14 on the substrate 3 at the predetermined position; then pour the model material 4 on the substrate 3 to solidify the model material 4; finally, the micro-channel mold is removed from the cured The model material 4 is extracted, and the two ends of the microchannel 2 are punched with a puncher to form the microchannel inlet 1 and the microchannel outlet 6, and the manufacturing of the detection device is completed. The material of the aforementioned substrate 3 is glass. The four lead ends of the two single-layer coils 7 and 14 are arranged outside the model material 4 and are not poured by the model material 4. The model material 4 is polydimethylsiloxane or polymethyl meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com