Experiment system and method for rock breaking efficiency analysis of TBM disc cutter

A technology of rock-breaking efficiency and disc-shaped hob, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc. Simulate the working process of the tool and other issues to achieve the effect of complete parameters and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

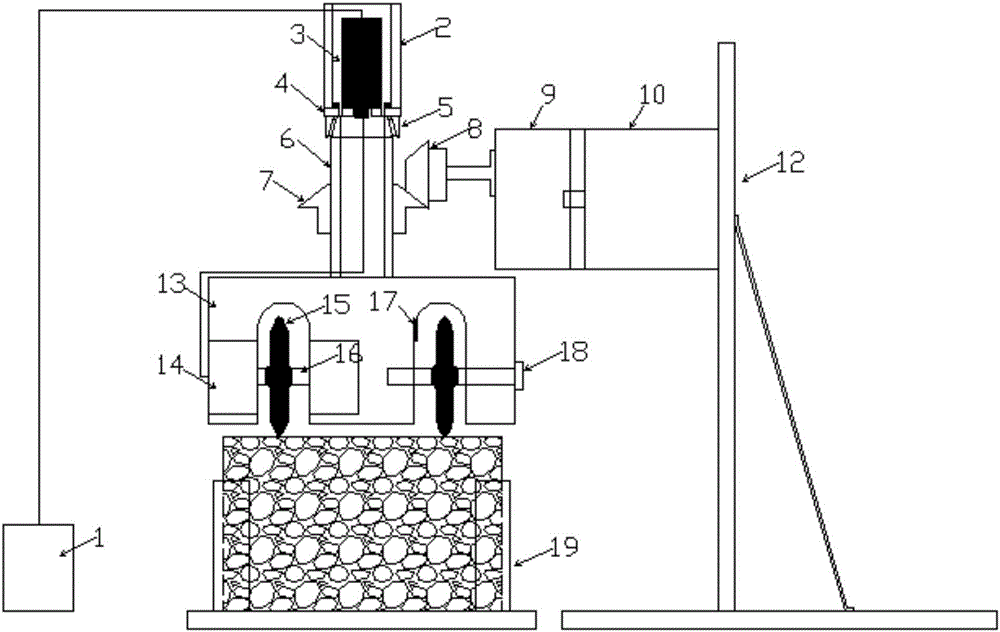

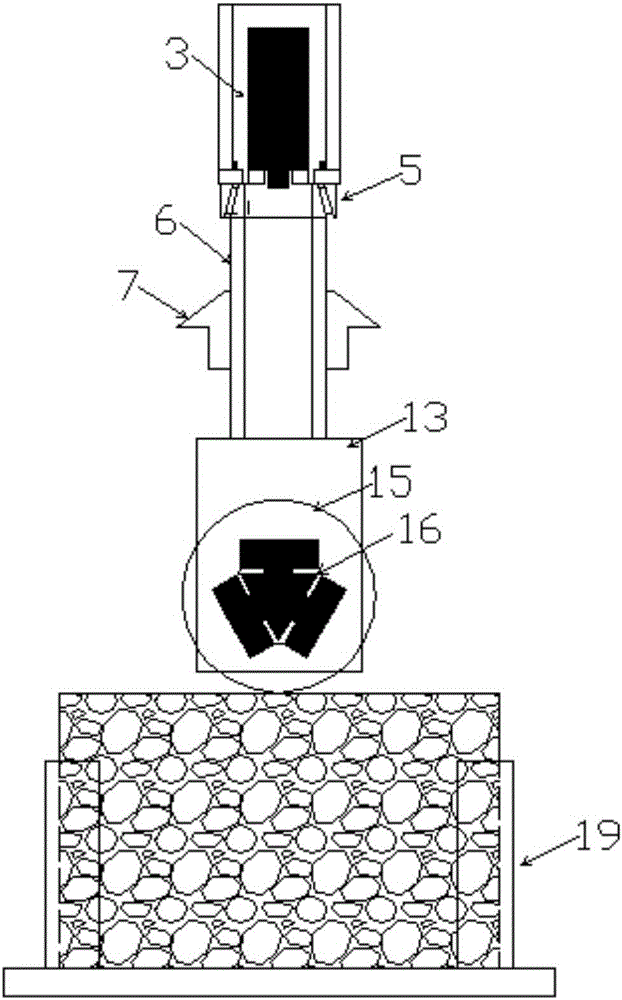

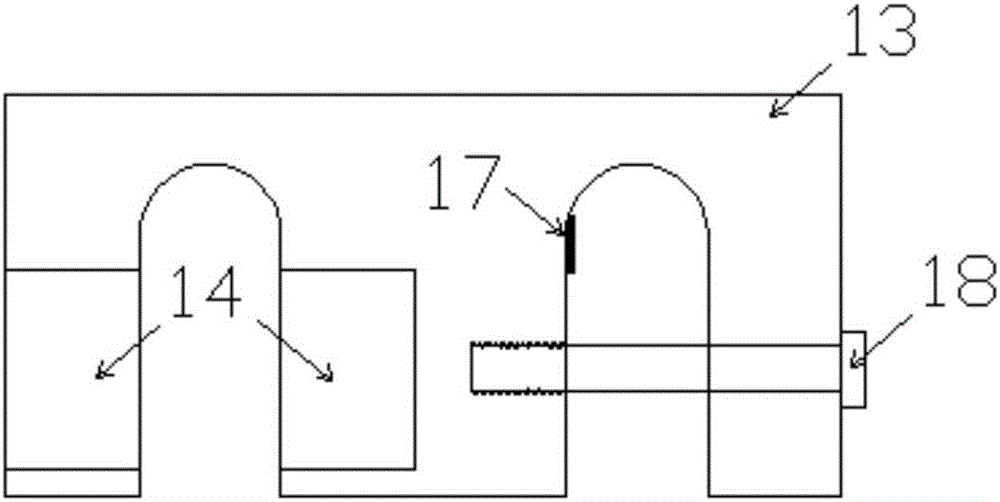

[0068] An experimental system for rock breaking efficiency analysis of a TBM disc hob, including a data acquisition box 1, a stator part, a rotor part, a monitoring system and a power system;

[0069] Stator part: including the upper rod 2 and the press;

[0070] The head of the press is connected to the top of the upper rod 2 for applying downward pressure to the upper rod 2;

[0071] As an optimization, the stator part also includes a wire slip ring 3 and a gasket 4;

[0072] The wire slip ring 3 is arranged in the upper rod 2;

[0073] The gasket 4 is arranged between the bottom of the upper rod 2 and the top of the connector, and the upper surface of the gasket 4 is fixedly connected to the bottom of the upper rod 2. During specific implementation, the two can be welded together to ensure Connection strength, the lower surface of the gasket 4 is fixedly connected with the connector;

[0074] The wire slip ring 3 is fixedly connected to the upper surface of the washer 4 ...

Embodiment 2

[0098] A method for analyzing the rock-breaking efficiency of a TBM disc-shaped hob adopts the experimental system for analyzing the rock-breaking efficiency of the TBM disc-shaped hob described in Embodiment 1, and the specific steps are as follows:

[0099] S1: Set a rock sample base 19 under the M-shaped cutter head 13, and fix the rock sample base 19 on the pressure table,

[0100] The rock sample is fixed on the rock sample base 19, and the height is adjusted by the rock sample base 19;

[0101] S2: Record the individual weighing of the scale hob 15 as m 1 ;The press starts to pressurize the upper rod 2 to stabilize the pressure at a certain value F;

[0102] S3: adjust the height of the motor 10, so that the large bevel gear 7 and the small bevel gear 8 are tightly meshed;

[0103] S4: Start the motor 10, use the governor 9 to stabilize the speed of the motor 10 at the value ω, transmit it through the bevel gear with a transmission ratio of 2:1, and the speed of the M-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com