Light fixture for generating power through photovoltaic temperature difference waste heat

A technology of waste heat power generation and temperature difference power generation, which is applied to semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, which can solve problems such as increased contact surface, increased contact surface thermal resistance, and stability effects, and achieves reduced thermal resistance and efficient heat conduction , strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

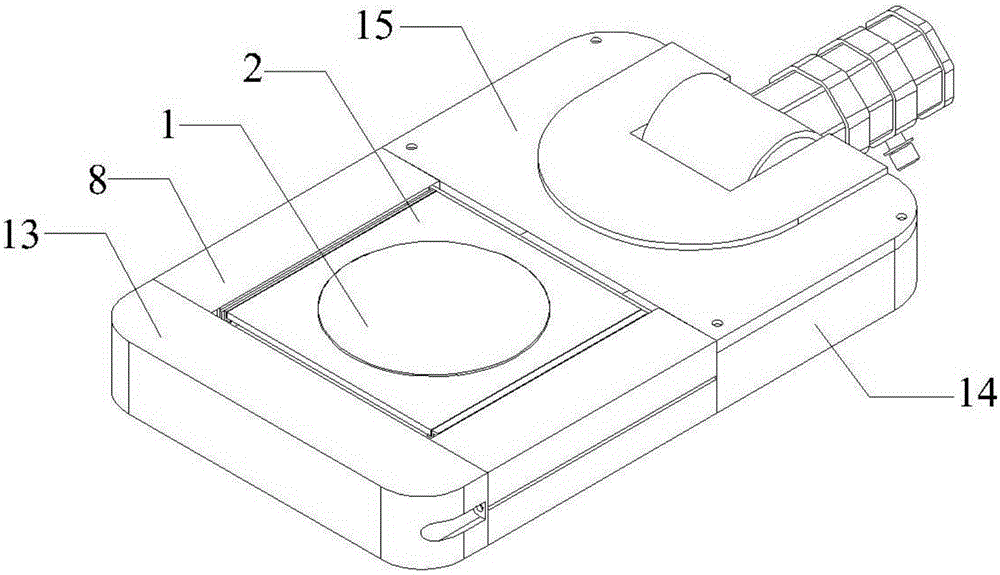

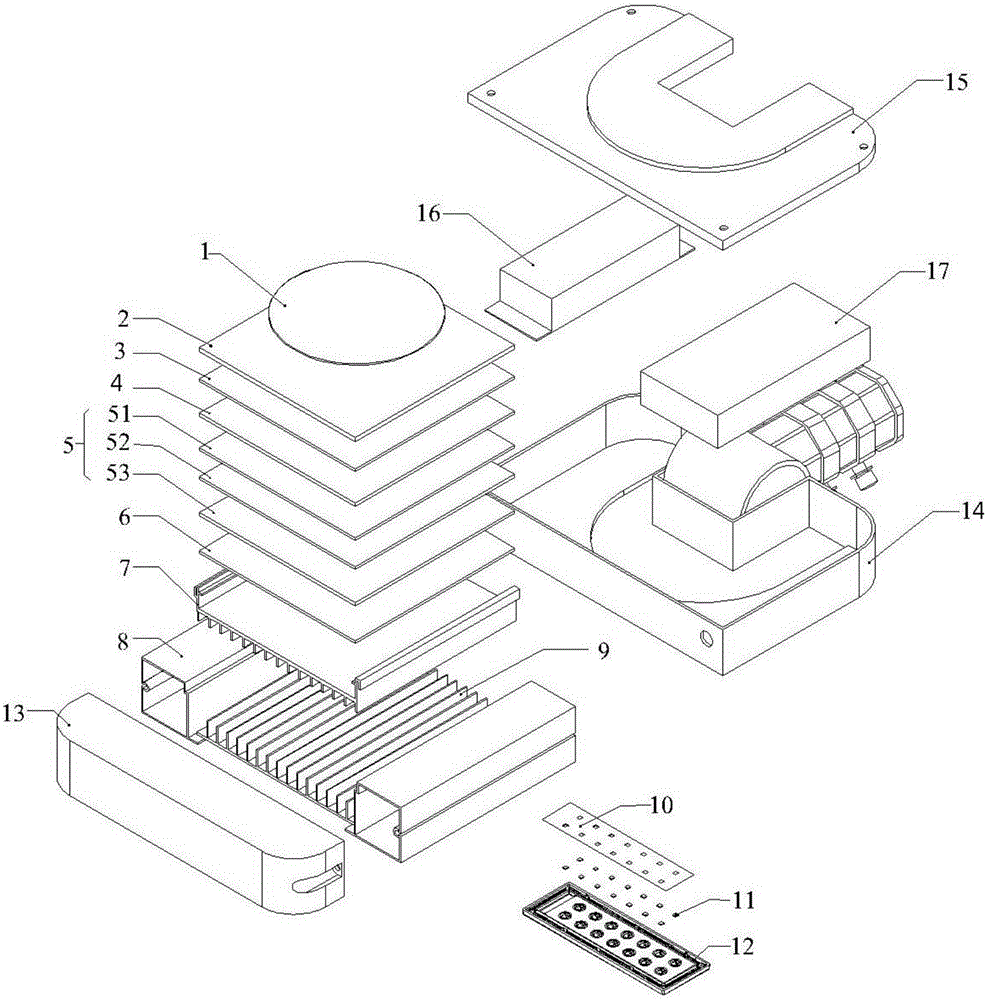

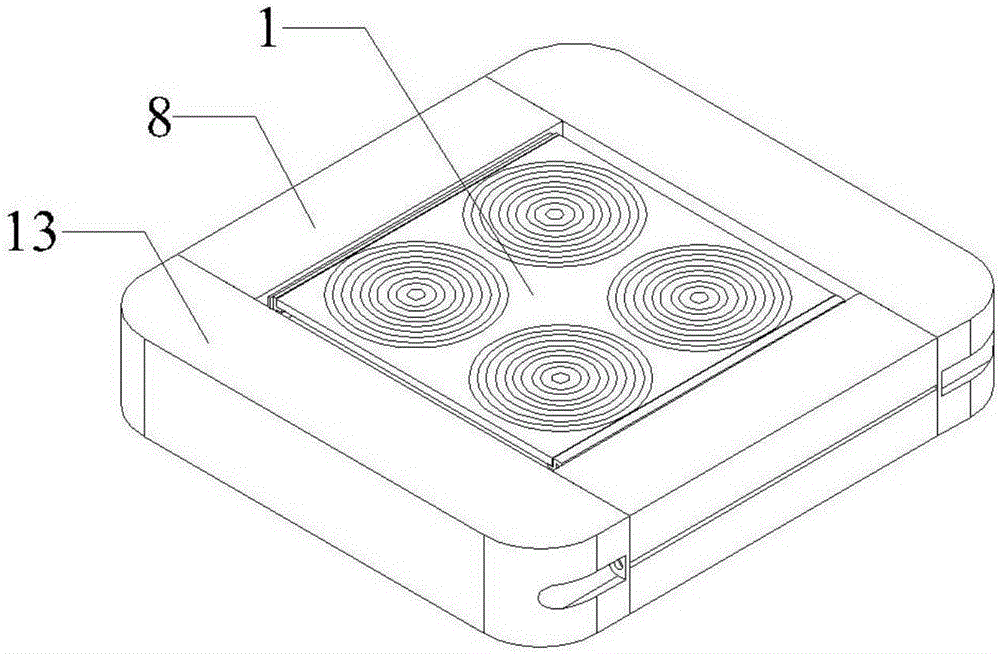

[0024] Such as figure 1 , 2 As shown, it is a preferred embodiment of the present invention, consisting of a condenser lens 1, a glass 2, a protective layer 3, a solar power generation panel 4, a thermoelectric power generation chip 5, an insulating layer 6, a second radiator 7, a bracket 8, a first Radiator 9, substrate 10, LED light source 11, light source lens 12, side cover 13, base 14, cover plate 15, controller 16, energy storage device 17, etc. The lower end of the bracket 8 is fixed with a first radiator 9 , the installation plane of the first radiator 9 is fixed with an LED light source 11 , the upper end of the bracket 8 is fixed with a solar thermoelectric power generation structure, and the front end of the bracket 8 section side is connected with a side cover 13 .

[0025] The structure of solar thermoelectric power generation is mainly composed of condenser lens 1, glass 2, protective layer 3, solar power generation panel 4, thermoelectric power generation chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com