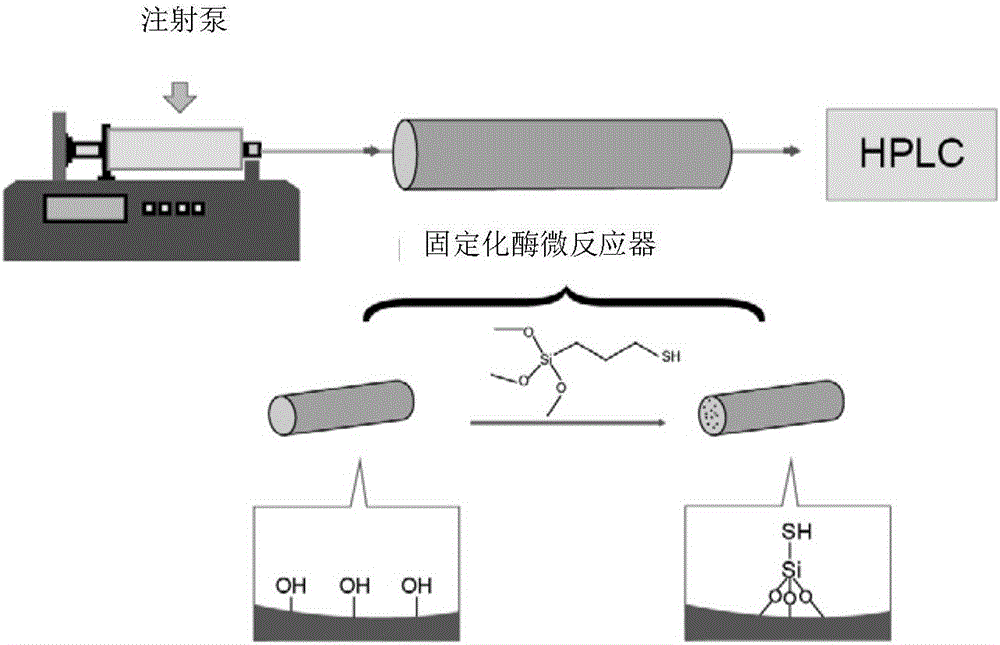

Method for continuous hydrolysis of cellobiose in straw by utilization of immobilized enzyme microreactor

A technology of microreactor and cellobiose, applied in the direction of enzyme production/bioreactor, immobilized on or in the inorganic carrier, biochemical equipment and methods, etc., to reduce energy consumption, reduce usage, and improve enzymatic hydrolysis efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select a 300 cm quartz capillary with an inner diameter of 530 microns. Connect the injection needle with PTFE tube and install it on the injection pump. First, 20% V / V HF aqueous solution was continuously poured into the quartz capillary at a flow rate of 20 μL / min for 30 minutes, washed with purified water until neutral, 1 mol / L hydrochloric acid was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, rinsed with purified water until Neutral, 1mol / L NaOH aqueous solution was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, and washed with purified water until neutral. The treated quartz tube was blown dry with nitrogen gas. A toluene solution of 10% V / V (3-mercaptopropyl)trimethoxysilane was continuously poured into the quartz capillary at a rate of 1 μL / min for 12 hours. Finally, absolute ethanol was continuously poured into the quartz capillary at a rate of 20 μL / min for 100 minutes, and dried.

[0028] The enzym...

Embodiment 2

[0032] Select a 300 cm quartz capillary with an inner diameter of 530 microns. Connect the injection needle with PTFE tube and install it on the injection pump. First, 20% V / V HF aqueous solution was continuously poured into the quartz capillary at a flow rate of 20 μL / min for 30 minutes, washed with purified water until neutral, 1 mol / L hydrochloric acid was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, rinsed with purified water until Neutral, 1mol / L NaOH aqueous solution was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, and washed with purified water until neutral. The treated quartz tube was blown dry with nitrogen gas. A 10% V / V toluene solution of (3-mercaptopropyl)trimethoxysilane was continuously poured into the quartz capillary at a rate of 1 μL / min for 8 hours. Finally, absolute ethanol was continuously poured into the quartz capillary at a rate of 20 μL / min for 100 minutes, and dried.

[0033] The enzyme...

Embodiment 3

[0037] Select a 300 cm quartz capillary with an inner diameter of 530 microns. Connect the injection needle with PTFE tube and install it on the injection pump. First, 20% V / V HF aqueous solution was continuously poured into the quartz capillary at a flow rate of 20 μL / min for 30 minutes, washed with purified water until neutral, 1 mol / L hydrochloric acid was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, rinsed with purified water until Neutral, 1mol / L NaOH aqueous solution was continuously poured into the quartz capillary at 30 μL / min for 100 minutes, and washed with purified water until neutral. The treated quartz tube was blown dry with nitrogen gas. A toluene solution of 10% V / V (3-mercaptopropyl)trimethoxysilane was continuously poured into the quartz capillary at a rate of 1 μL / min for 10 hours. Finally, absolute ethanol was continuously poured into the quartz capillary at a rate of 20 μL / min for 100 minutes, and dried.

[0038] The enzym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com