Functional biodegradable material and preparation method thereof

A biodegradable material and functionalized technology, applied in the field of functionalized biodegradable materials and their preparation, can solve the problems such as the inability of artificial adjustment and control of the degradation cycle, the inability to meet the mechanical properties, and the inability to recycle the products, so as to overcome the problems of non-degradability. , Controllable degradation cycle, controllable rust period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

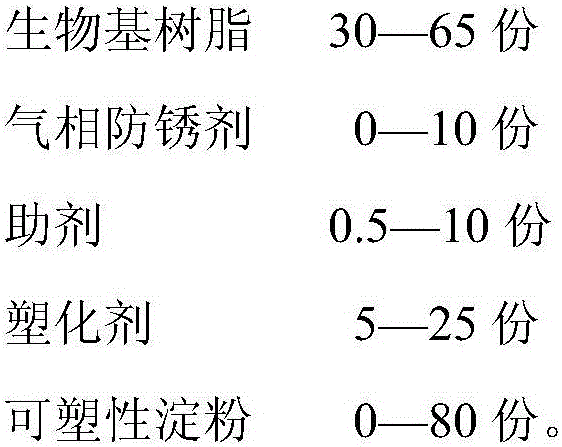

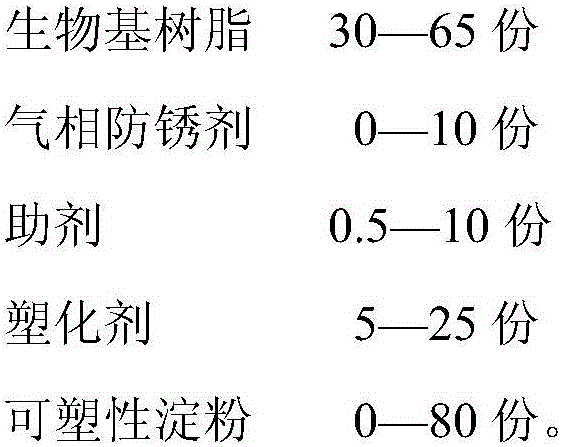

[0028] (1) Prepare raw materials:

[0029] 30 parts of polyvinyl alcohol-1799, 2 parts of dioctyl formate, 1 part of cyclohexylamine, 1 part of o-nitrophenol sodium salt, 0.5 parts of additives, 3 parts of propylene glycol, 2 parts of glyceryl triacetate, 20 parts of plastic starch .

[0030] Described auxiliary agent is made up of the material of following percentage by weight:

[0031] ① Antibacterial and antibacterial agent: nano-silver ion fluorspar, 5%;

[0032] ②Lubricant: calcium stearate, 45%;

[0033] ③Antioxidant: Antioxidant 1010, 25%;

[0034] ④ Nucleating agent: calcium carbonate, 10%;

[0035] ⑤ Surfactant: silane coupling agent, 15%.

[0036] (2) Preparation of functionalized biodegradable materials: first weigh the additives described in step (1) according to the proportion, put them into the reaction tank, stir while heating, melt at 45°C, cool and take out for later use. Then mix other raw materials and prepared additives into a high-speed mixer, stir w...

Embodiment 2

[0038] (1) Prepare raw materials:

[0039] 65 parts of polylactic acid, 4 parts of benzotriazole, 6 parts of monoethanolamine, 10 parts of additives, 5 parts of citric acid, 3 parts of glyceryl monostearate, 4 parts of N-hydroxyethyl formamide, hydroxyalkane 1 part of methyl formamide, 12 parts of ethylene diformamide, 80 parts of plastic starch.

[0040] Described auxiliary agent is made up of the material of following percentage by weight:

[0041] ① Antibacterial and antibacterial agent: sodium alginate, 10%;

[0042] ②Lubricant: polyoxyethylene ester, 25%;

[0043] ③Antioxidant: Antioxidant 168, 45%;

[0044] ④ Nucleating agent: silicon dioxide, 5%;

[0045] ⑤ Surfactant: titanate coupling agent, 15%.

[0046] (2) Preparation of functionalized biodegradable materials: first weigh the additives described in step (1) according to the proportion, put them into the reaction tank, stir while heating, melt at 60°C, cool and take out for later use. Then mix other raw materi...

Embodiment 3

[0048] (1) Prepare raw materials:

[0049] 40 parts of polyhydroxyalkanoate, 1 part of phytic acid, 3 parts of triethanolamine, 0.5 parts of additives, 3 parts of acetamide, 7 parts of triethyl citrate, 35 parts of plastic starch.

[0050] Described auxiliary agent is made up of the material of following percentage by weight:

[0051] ① Antibacterial and antibacterial agent: chitosan, 10%;

[0052] ②Lubricant: oleic acid amide, 30%;

[0053] ③Antioxidant: Antioxidant TZP, 40%;

[0054] ④ Nucleating agent: talcum powder, 8%;

[0055] ⑤ Surfactant: sucrose fatty acid ester, 12%.

[0056] (2) Preparation of functionalized biodegradable materials: first weigh the additives described in step (1) according to the proportion, put them into the reaction tank, stir while heating, melt at 60°C, cool and take out for later use. Then mix other raw materials and prepared additives into a high-speed mixer, stir while raising the temperature, mix at 45-95°C for 60 minutes, then cool the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com