A preparing method of a controllable long-acting slow-release sodium nitrite corrosion inhibitor microcapsule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

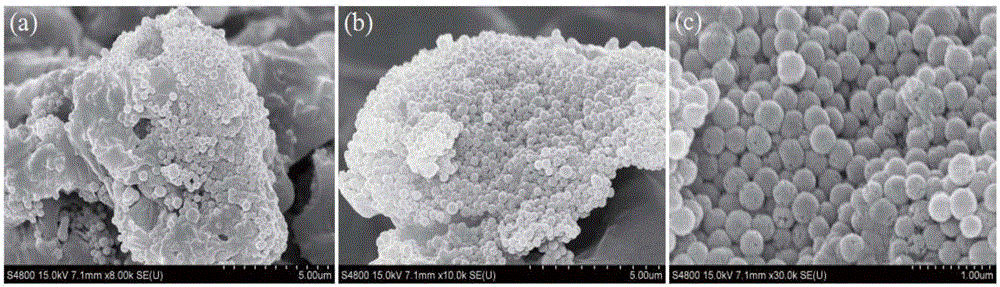

Image

Examples

Embodiment 1

[0021] (1) Weigh a certain mass ratio of methylene chloride, petroleum ether, Span 80 and cetyl trimethyl ammonium bromide in a high-speed emulsifier, dichloromethane, petroleum ether, Span 80 and cetyl Trimethylammonium bromide accounts for 30%, 52.83%, 0.7%, 0.3% of the total weight of the feed, and then a certain mass ratio of styrene, methacrylic acid, glycidyl methacrylate and azo are added to the emulsifier Diisobutyronitrile mixed solution, styrene, methacrylic acid, glycidyl methacrylate and azobisisobutyronitrile respectively account for 7%, 0.6%, 1.5%, 0.07% of the total weight of the feed, and the speed is 15000~20000r Adjust the emulsification and dispersion for 10-15 minutes and then move it into the reactor;

[0022] (2) Add sodium nitrite accounting for 7% of the total weight of the feed into the reactor, react at 60-70°C for 5-7 hours, and raise the reaction temperature to 90-95°C for 3-4 hours;

[0023] (3) Cool to room temperature, wash with water twice, and coll...

Embodiment 2

[0029] (1) Weigh a certain mass ratio of methylene chloride, petroleum ether, Span 80 and cetyl trimethyl ammonium bromide in a high-speed emulsifier, dichloromethane, petroleum ether, Span 80 and cetyl Trimethylammonium bromide accounted for 35%, 40.8%, 0.9%, 0.5% of the total weight of the feed, and then added a certain mass ratio of styrene, methacrylic acid, glycidyl methacrylate and azo into the emulsifier Diisobutyronitrile mixed solution, styrene, methacrylic acid, glycidyl methacrylate and azobisisobutyronitrile respectively account for 10%, 0.9%, 1.8%, 0.1% of the total weight of the feed, and the speed is 15000~20000r Adjust the emulsification and dispersion for 10-15 minutes and then move it into the reactor;

[0030] (2) Add sodium nitrite accounting for 10% of the total weight of the feed into the reactor, react at 60-70°C for 5-7 hours, and raise the reaction temperature to 90-95°C for 3 to 4 hours;

[0031] (3) Cool to room temperature, wash with water twice, and co...

Embodiment 3

[0033] (1) Weigh a certain mass ratio of methylene chloride, petroleum ether, Span 80 and cetyl trimethyl ammonium bromide in a high-speed emulsifier, dichloromethane, petroleum ether, Span 80 and cetyl Trimethylammonium bromide accounts for 32%, 49.62%, 0.7%, 0.4% of the total weight of the feed, and then a certain mass ratio of styrene, methacrylic acid, glycidyl methacrylate and azo are added to the emulsifier Diisobutyronitrile mixed solution, styrene, methacrylic acid, glycidyl methacrylate and azobisisobutyronitrile accounted for 8%, 0.7%, 1.5%, 0.08% of the total weight of the feed, and the speed is 15000~20000r Adjust the emulsification and dispersion for 10-15 minutes and then move it into the reactor;

[0034] (2) Add sodium nitrite accounting for 7% of the total weight of the feed into the reactor, react at 60-70°C for 5-7 hours, and raise the reaction temperature to 90-95°C for 3-4 hours;

[0035] (3) Cool to room temperature, wash with water twice, and collect the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com