A live core drive two-end powder bushing picker

A picker and two-head technology, which is applied in the field of two-headed powder bushing pickers driven by live cores, can solve problems such as pressing shaking, unstable holding and releasing of tweezers, and inconvenient hand pressing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

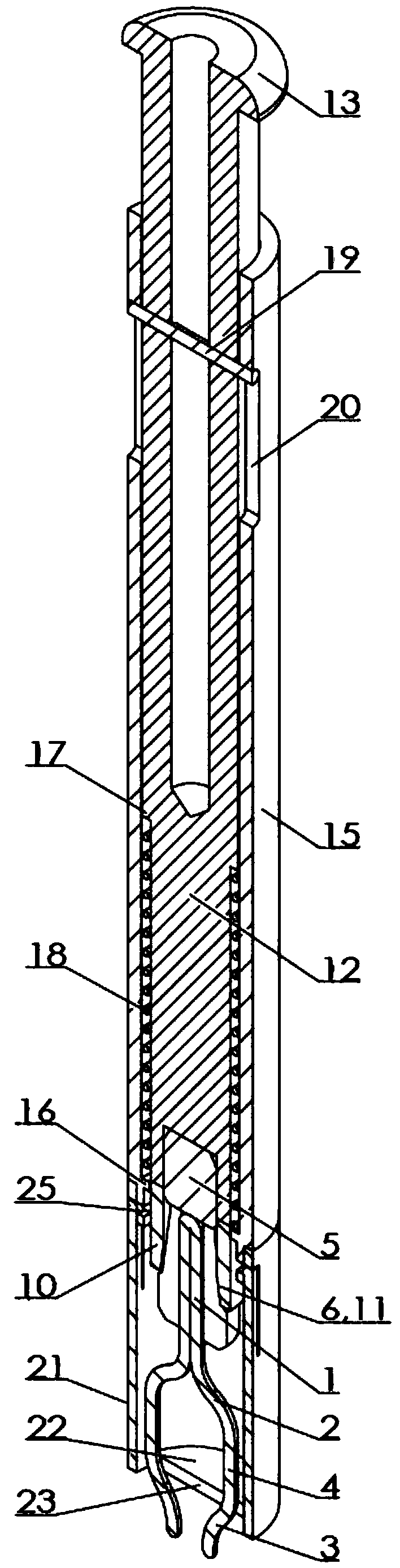

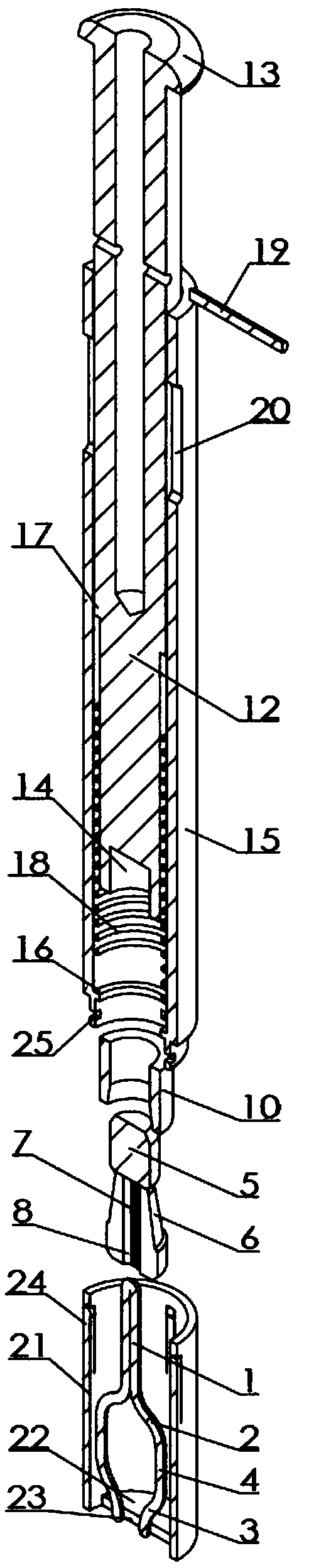

[0011] Examples of the present invention figure 1 , 2 As shown, the live core drives the two-end powder bushing picker with a pick-up part and a handle part. The pick-up part is equipped with a chuck and an elastic wire. The upper section 1 of the elastic yarn in the left half and the right half is a straight section close together, the middle section 2 of the left half and the right half gradually bends outward, and the lower section 3 of the left half and the right half gradually bends inward. Receive, the connection between the lower section and the middle section forms an arc arch, and the arc arch can be an arc-shaped vault at one end, or a straight section. The connection between the lower section and the middle section of this embodiment is connected by a transition section 4, and the transition section is in a vertical state. It can be in better contact with the inner wall of the shaft sleeve, and the connection is more stable. The elastic wire can be bent from metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com