A kind of piston processing method

A processing method and piston technology, which is applied in the field of pistons, can solve problems such as time-consuming, labor-consuming, and errors, and achieve the effects of reducing wear, improving clamping fastness, and preventing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

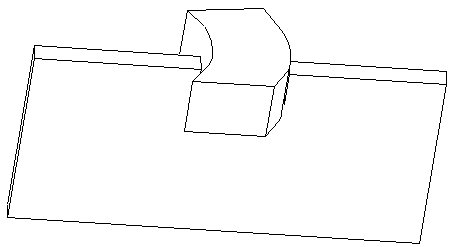

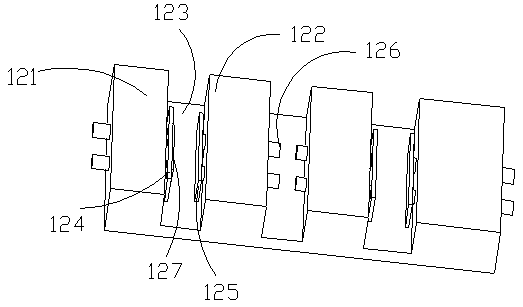

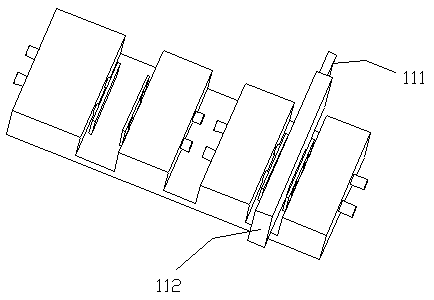

Image

Examples

Embodiment Construction

[0068] In order to further describe the present invention, it will be further described in the following embodiments.

[0069] The invention discloses a piston processing method, which includes the following steps:

[0070] (1) Material selection: select the finished aluminum ingot or mix the finished aluminum ingot and the reheated aluminum material according to the mass ratio of 4:1; among them, the AC4B aluminum ingot is preferably used for the finished aluminum ingot.

[0071] (2) Smelting: Put the aluminum material in a crucible and heat it to 780~800℃; scoop the molten aluminum into the holding furnace, and when the temperature is controlled at 750~770℃, add a slag cleaning agent for inventory treatment; then add deterioration Use a bell jar to press it to below the molten aluminum level and stir; among them, the mass ratio of the modifier to the molten aluminum is 1.2~1.5:500; the degassed molten aluminum is treated with a degasser and set Parameters: Nitrogen pressure 0.4-0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com