Preparation of nitrogen doping carbon nanometer fiber adsorption material for carbon dioxide adsorption separation

A technology of carbon nanofibers and adsorption materials, applied in fiber treatment, separation methods, separation of dispersed particles, etc., can solve the problems of poor adsorption selectivity of carbon nanofibers, and meet the needs of carbon dioxide capture, good adsorption capacity, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

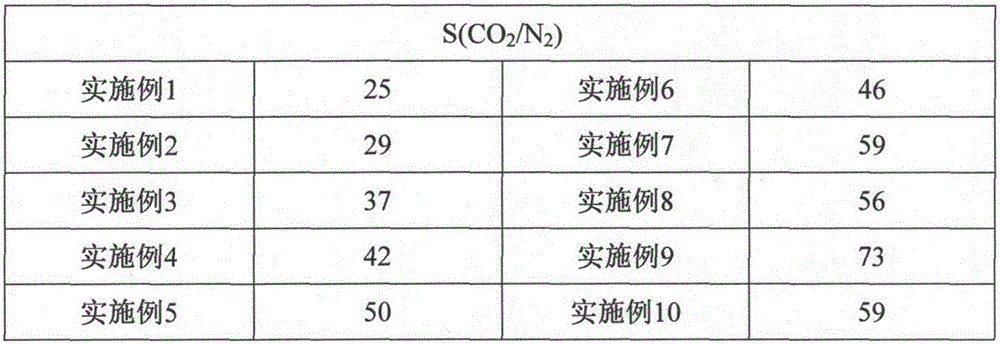

Examples

Embodiment 1

[0024] A preparation method of nitrogen-doped carbon nanofiber adsorption material for carbon dioxide adsorption and separation, the specific steps are:

[0025] (1) At room temperature of 25°C, first add 0.05g of pyrrole to 9.45g of N,N-dimethylformamide and stir for 1 hour to obtain a solution, then add 0.5g of polyacrylonitrile to the above solution and stir until completely dissolved, Obtain electrospinning raw material, wherein, the mass fraction of polyacrylonitrile is 5.5%, the mass fraction of pyrrole is 0.5%;

[0026] (2) Add the obtained electrospinning raw material into the electrospinning device, and carry out electrospinning under the condition that the static voltage is 10kV, the flow rate of the syringe pump is 0.3mL / h, and the distance between the spinneret and the receiving screen is 6cm, and the obtained Nitrogen-containing hybrid nanofibrous materials;

[0027] (3) Carbonize the nitrogen-containing hybrid nanofibrous material. The specific steps are: first ...

Embodiment 2

[0030] A preparation method of nitrogen-doped carbon nanofiber adsorption material for carbon dioxide adsorption and separation, the specific steps are:

[0031] (1) At room temperature 25°C, first add 0.05g of pyrrole to 9.25g of N,N-dimethylformamide and stir for 1h to obtain a solution, then add 0.7g of polyimide to the above solution and stir until completely dissolved , obtain electrospinning raw material, wherein, the mass fraction of polyimide is 7.5%, the mass fraction of pyrrole is 0.5%;

[0032] (2) Add the obtained electrospinning raw material into the electrospinning device, and carry out electrospinning under the condition that the static voltage is 15kV, the flow rate of the syringe pump is 0.5mL / h, and the distance between the spinneret and the receiving screen is 10cm, and the obtained Nitrogen-containing hybrid nanofibrous materials;

[0033](3) Carbonize the nitrogen-containing hybrid nanofiber material. The specific steps are: firstly heat up to 180°C under...

Embodiment 3

[0036] A preparation method of nitrogen-doped carbon nanofiber adsorption material for carbon dioxide adsorption and separation, the specific steps are:

[0037] (1) At room temperature of 25°C, first add 0.1g of urea-formaldehyde resin to 8.9g of ethanol and stir for 2 hours to obtain a solution, then add 1g of polyvinyl butyral to the above solution and stir until completely dissolved to obtain the electrospinning raw material , wherein, the mass fraction of polyvinyl butyral is 11%, and the mass fraction of urea-formaldehyde resin is 1%;

[0038] (2) Add the obtained electrospinning raw material into the electrospinning device, and carry out electrospinning under the condition that the static voltage is 20kV, the flow rate of the syringe pump is 1mL / h, and the distance between the spinneret and the receiving screen is 15cm, and the obtained Nitrogen hybrid nanofibrous materials;

[0039] (3) Carbonize the nitrogen-containing hybrid nanofiber material. The specific steps ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com